Sensor device

A sensor device and sensor technology, applied in the direction of sensors, caliper sensors, mechanical equipment, etc., can solve problems such as time-consuming, and achieve the effect of reducing production time, fast and instant identification, and reducing the amount of particulate matter

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

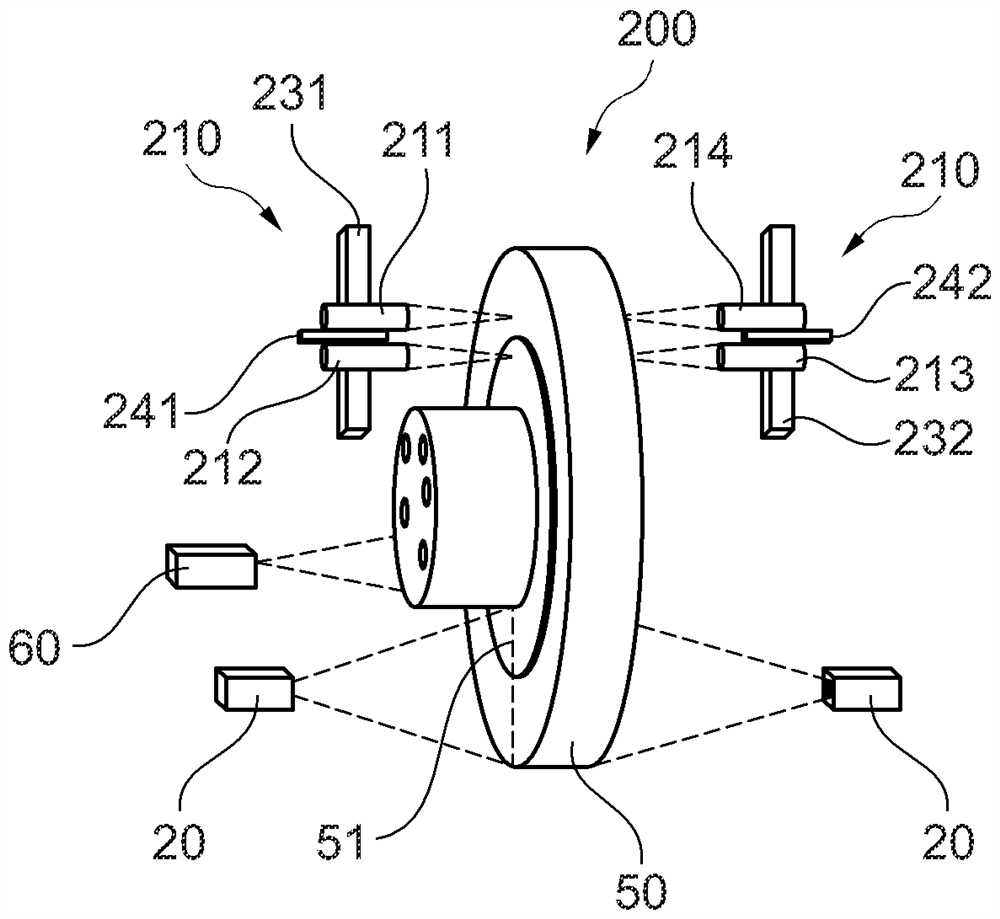

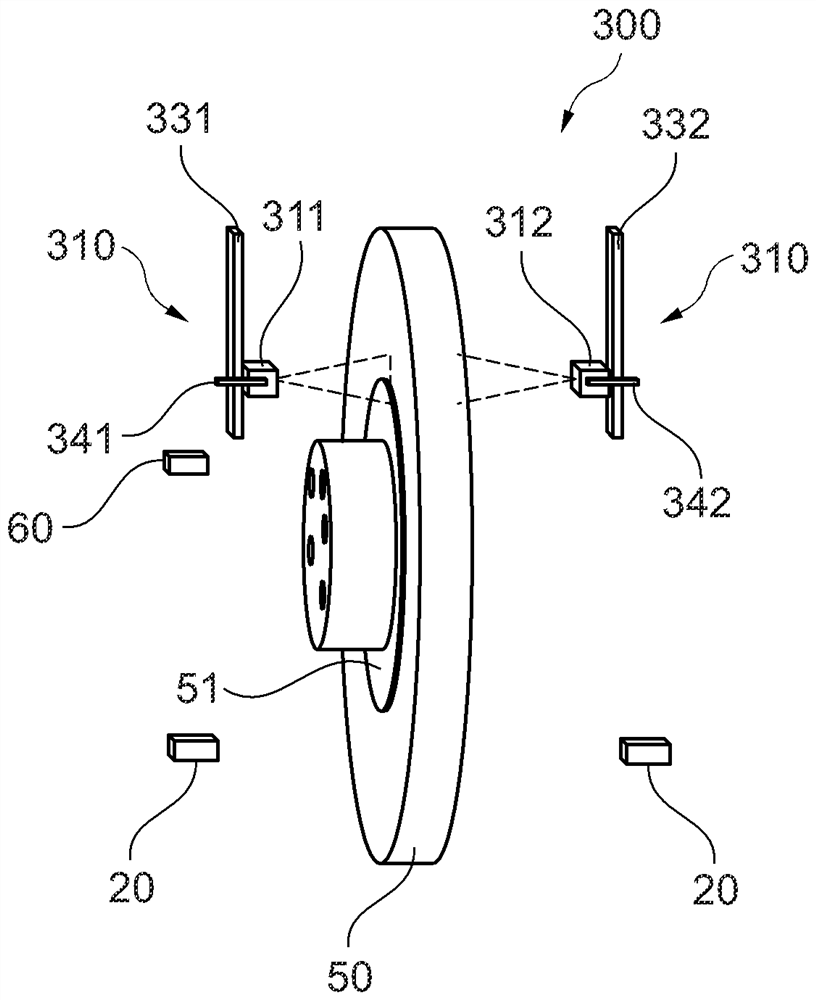

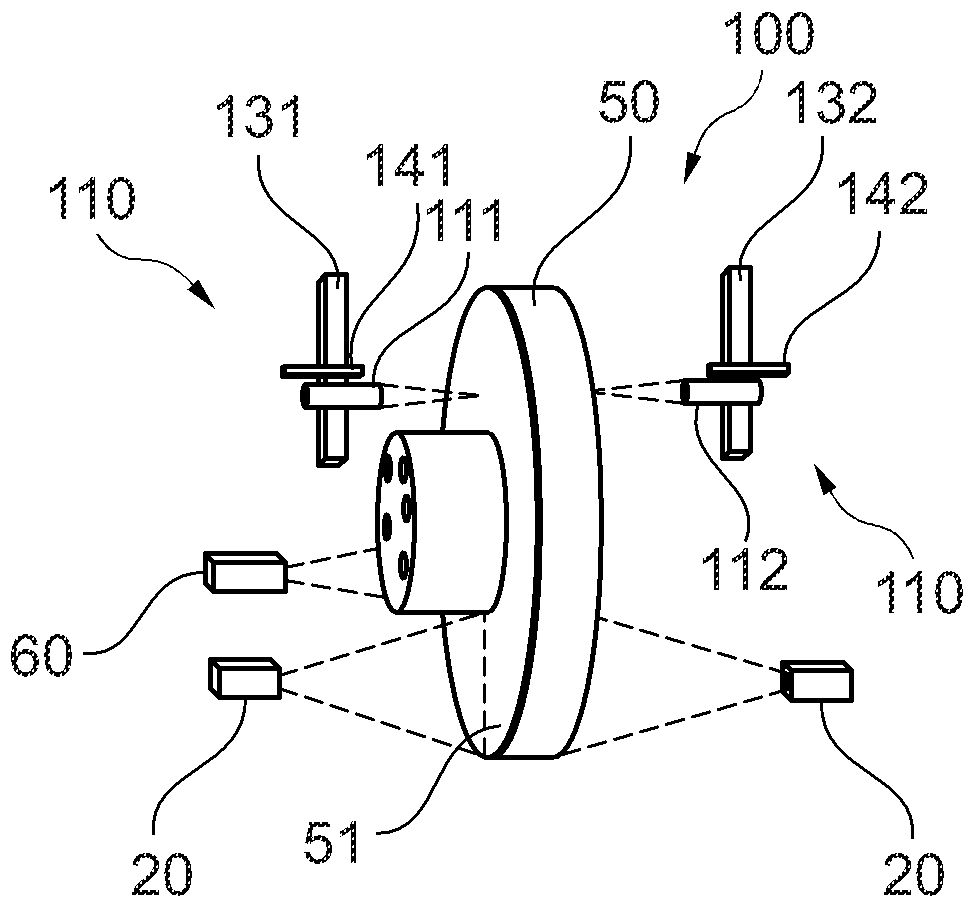

[0044] figure 1 A first embodiment of a sensor device 100 according to the invention is shown. The sensor device according to the invention comprises a first optical sensor system 110 consisting of two parts. Each part of this sensor system 110 is arranged on opposite sides of a disc 50, which may in particular be a brake disc. As already described, the object of the sensor device 100 according to the invention is to determine the layer thickness of the coating of the disc 50 .

[0045] Each subunit of the first optical sensor system 110 comprises an optical sensor 111 , 112 . Each of these sensors 111 , 112 is fastened to a linear guide 131 , 132 and additionally comprises an adjuster 141 , 142 .

[0046] Confocal color sensors that determine the distance from the corresponding side of the disk 50 can be used here as optical sensors 111 , 112 .

[0047] Furthermore, a second optical sensor system 20 is provided, which can be designed, for example, in the form of a line sc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com