Precision optical machine assembly method of trapezoidal prism optical system

A trapezoidal prism and optical system technology, applied in optics, optical components, installation, etc., can solve the problems of low assembly accuracy, unable to meet the high-precision assembly requirements of the trapezoidal prism optical path, etc., and achieve the effect of high-precision reference conversion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

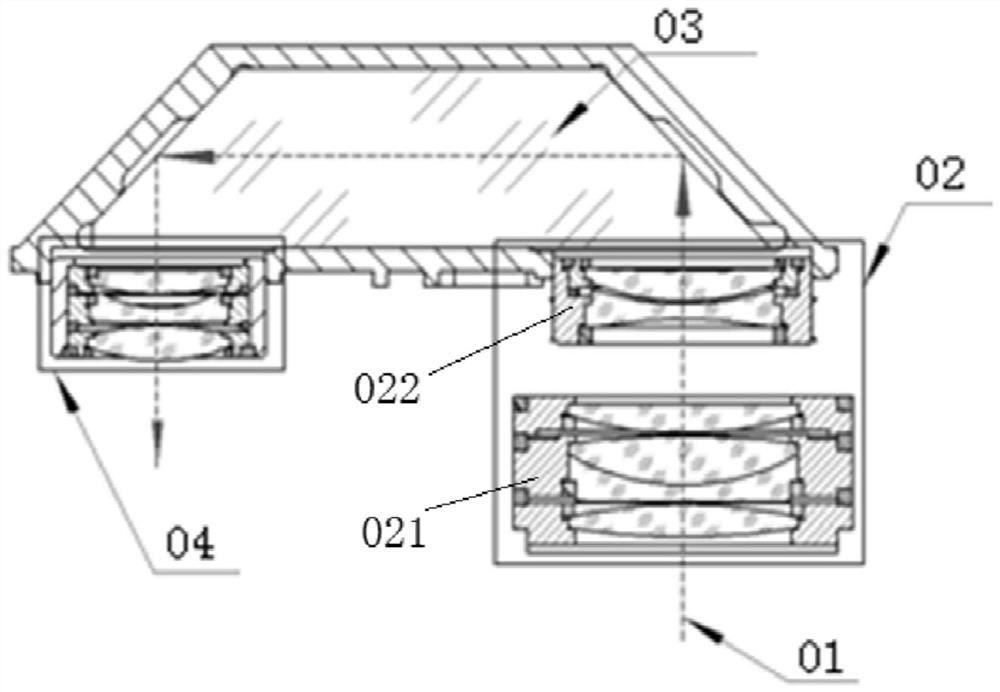

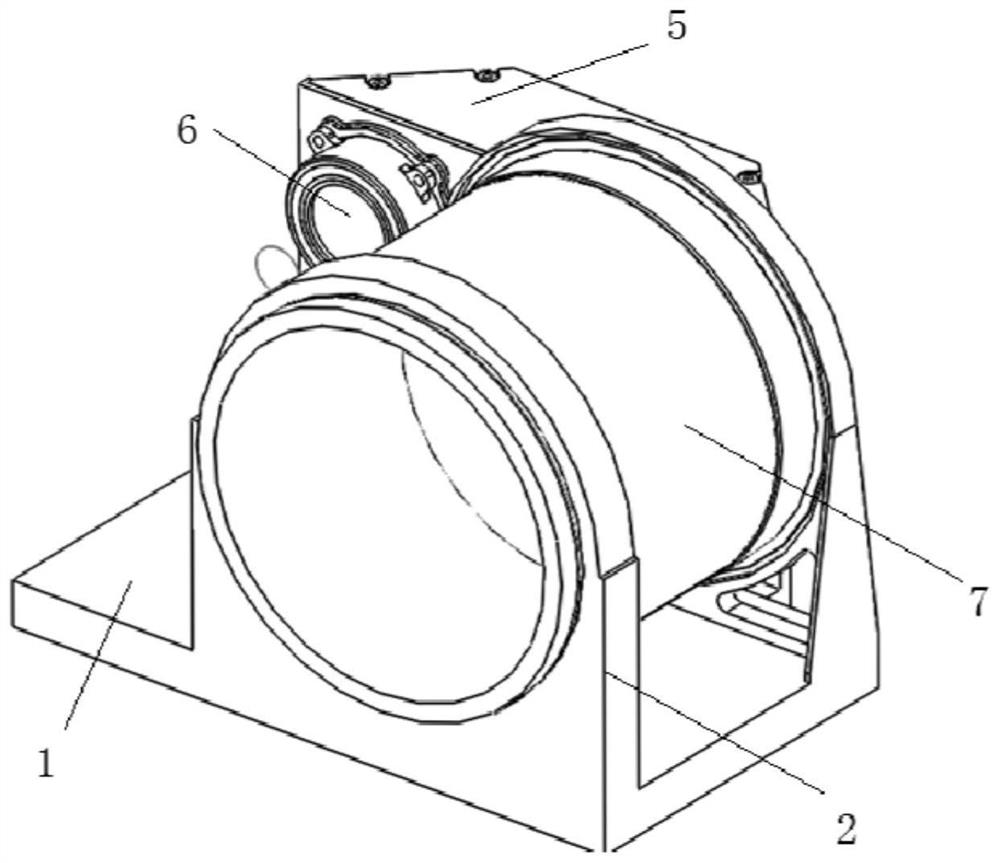

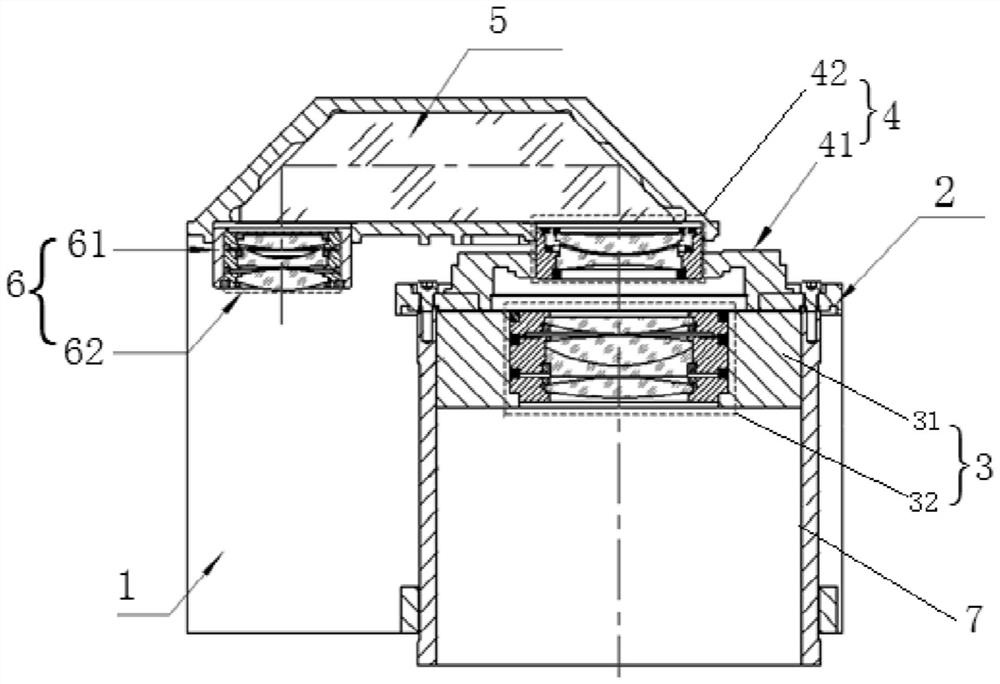

[0091] like figure 2 and image 3 As shown, a trapezoidal prism optical system includes a base plate 1, a bracket 2, a long barrel 7, a first front-end optical assembly 3, a second front-end optical assembly 4, a trapezoidal prism 5, and a rear-end optical assembly 6; the first front-end optical assembly Assembly 3 includes a first lens barrel 31 and a first front lens group 32, a second front optical assembly 4 includes a second lens barrel 41 and a second front lens group 42, and a rear optical assembly 6 includes a third lens barrel 61 and a rear Optical lens group 62, the long lens barrel 7 is installed on the bracket 2 by screws, the first lens barrel 31 is assembled inside the long lens barrel 7; the second lens barrel 41 is installed on the bracket 2; the bottom plate 1 provides bottom mounting for all structures benchmark. In this embodiment, the cooperation between the first front-end lens group 32 and the first lens barrel 31, between the second front-end lens gro...

Embodiment 2

[0123] The difference from Embodiment 1 is that before the trapezoidal prism optical system is assembled, the first front end lens group 32 is not installed on the first lens barrel 31, the second front end lens group 42 is not installed on the second lens barrel 41, and the rear end lens group 42 is not installed on the second lens barrel 41. The third lens barrel 61 is not installed in the optical lens group 62, then the precision optomechanical assembly method of the trapezoidal prism optical system:

[0124] In step 1.2), before the first tool reticle 81 is loaded into the first lens barrel 31, the first front-end lens group 32 does not need to be removed;

[0125] In step 2.2), before the second tooling reticle 82 is loaded into the second lens barrel 41, it is not necessary to dismantle the second front end lens group 42;

[0126] In step 5.3), before the third tool reticle 83 is loaded into the third lens barrel 61 , the rear optical lens group 62 does not need to be di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com