A high-precision flat-nose pliers and its transmission part trapezoidal thread processing technology

A flat-nose pliers, high-precision technology, applied in the field of flat-nose pliers, can solve the problems of large scrap loss, reduced life of the whole pliers, large machining allowance, etc., to meet the requirements of ensuring assembly accuracy, improving processing efficiency, and reducing finishing allowance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

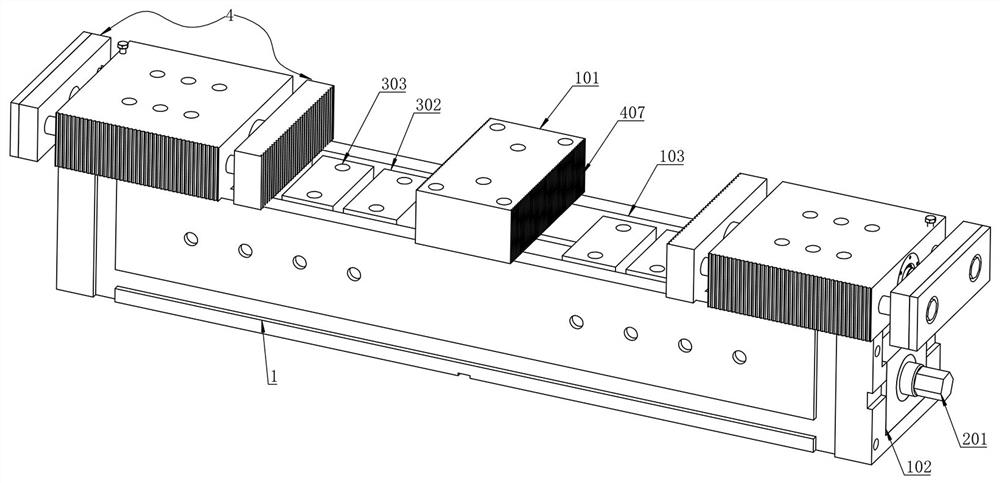

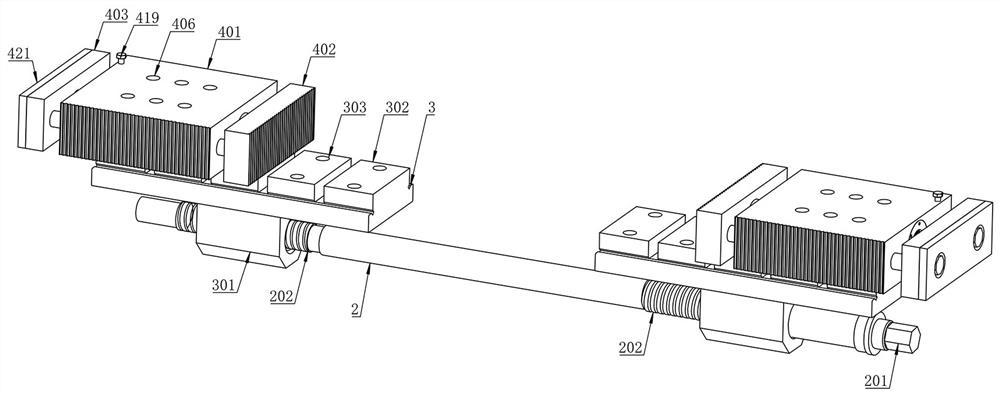

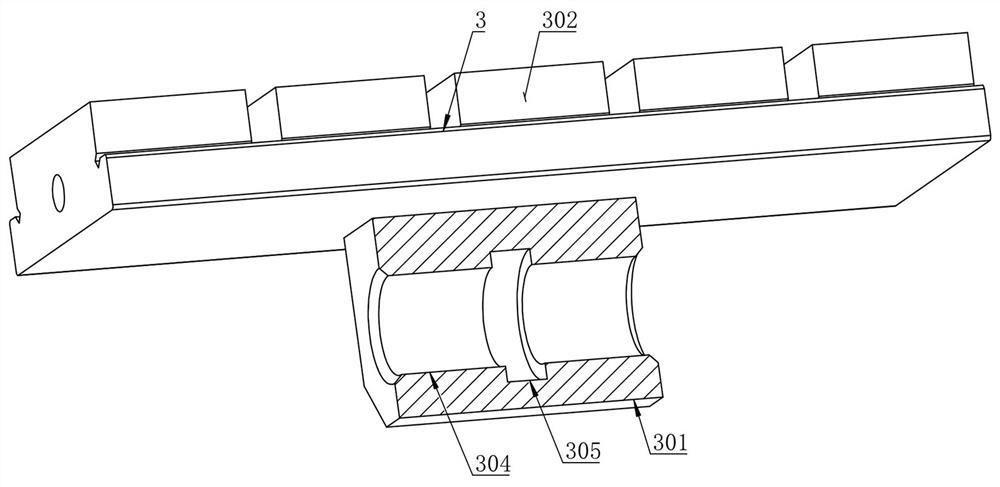

[0032] Specific implementation mode one: combine Figure 1-8As shown, a high-precision flat-nose pliers is characterized in that: a body base 1, a screw rod 2, a sliding seat 3 and a multidirectional adjustable lock body device 4; the top of the pliers body base 1 is fixedly provided with a fixed clamp block 101 Both sides of the pliers body base 1 are provided with fixing seats 102; the screw rod 2 is arranged in the middle of the two fixing seats 102; the right end of the screw rod 2 is provided with a spline shaft 201; the middle part of the screw rod 2 Both sides are symmetrically provided with threaded buttons 202; the spiral directions of the two threaded buttons 202 are opposite; a slide rail 103 is arranged above the inside of the pliers body base 1; the slide seat 3 is slidably connected to the slide rail 103; The bottom of the seat 3 is provided with a transmission sleeve 301; the transmission sleeve 301 is arranged on the threaded buckle 202; the upper side of the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com