Manufacturing and operating method of automatic loading, unloading, moving and transporting labor-saving trolley

A technology of automatic loading and unloading and small trolleys, which is applied to trolleys, motor vehicles, single-axis trolleys, etc., can solve the problems of large number of personnel, high labor costs, and low efficiency, and achieve the effects of convenient construction, low cost, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

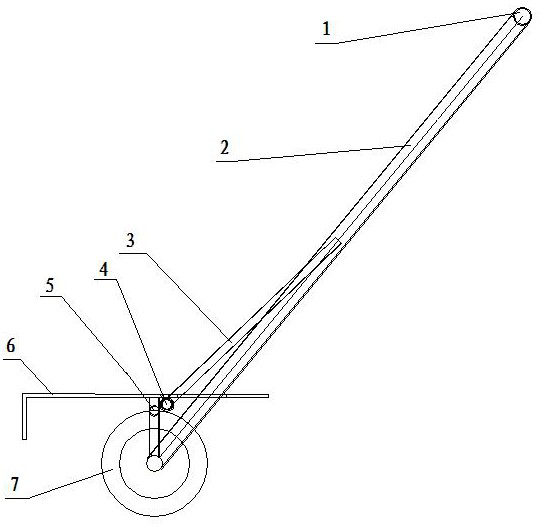

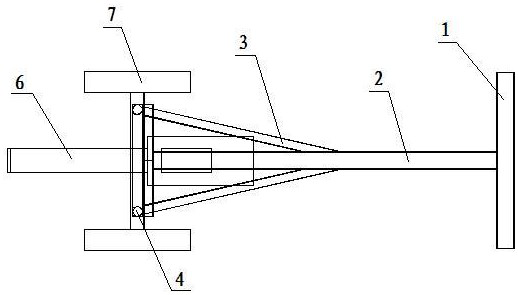

[0025] A labor-saving trolley for automatic loading, unloading and transporting, which consists of: a push rod, the push rod includes a cross bar 1, and the top 2 of the cross bar is welded with a vertical bar at the middle position to form a T-shaped structure. One end of the reinforcing bar 3 is respectively fixed on both sides of the vertical bar, the other end of the reinforcing bar is welded to the steel pipe 5, the bottom of the vertical bar is welded to the connecting shaft of the solid wheel 7, and passes through the L-shaped gripper pedal 6 square hole, the bottom of the L-shaped gripper pedal is connected with the swivel ring, the two ends of the connecting shaft are respectively fixed with the bearings in the solid wheel 7, and the two sides of the connecting shaft are respectively welded with vertical supporting steel pipes, so that The upper part of the vertical support steel pipe is welded with the horizontal support steel pipe.

Embodiment 2

[0027] According to the automatic loading, unloading, and labor-saving trolley described in Embodiment 1, the front end of the L-shaped gripper pedal adopts a steel plate with a thickness of 10mm and an L-shaped shape, and its rear end adopts a flat plate with a thickness of 10mm, and has In the square groove, the inner clear distance between the two wheels on the connecting shaft is greater than the side length of the prefabricated block by 40mm.

Embodiment 3

[0029] A method for making and operating a labor-saving trolley for automatic loading and unloading, the method includes the following steps:

[0030] (1) Manufacture of the described automatic loading, unloading, and labor-saving trolley:

[0031] First of all, the horizontal bar and the vertical bar are made of steel pipes with a diameter of 50 mm to form a T-shaped push rod, and the inverted V-shaped reinforcing rod is made of a steel pipe with a diameter of 20 mm to form a composite reinforced push rod;

[0032] The front end of the L-shaped gripper pedal is made of a 10mm thick steel plate, and the rear end is made of a 10mm thick steel plate. When loading and unloading objects exceeding 200KG, L-shaped ribs are required to form a composite reinforced L-shaped gripper. Pedal, the bottom of the L-shaped gripper pedal is welded with a steel pipe with a length of 70mm and a diameter of 40mm to connect the horizontal steel pipe of the support part to form a swivel of the L-sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com