Knitted garment

A clothing and knitting technology, applied in the field of knitted clothing, can solve the problems of lack of comfort and air permeability, and achieve the effects of excellent ventilation performance, improved comfort performance, and good comfort.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

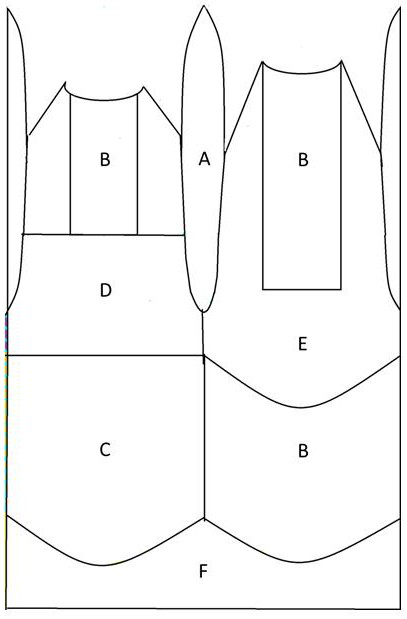

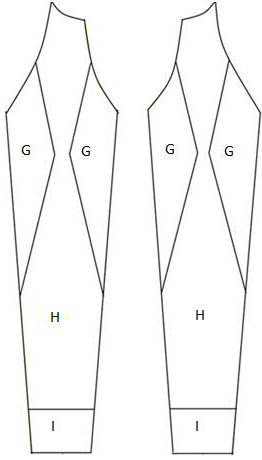

Image

Examples

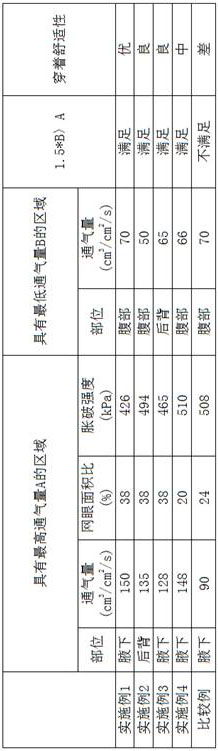

Embodiment 1

[0033] On the 28G single-sided seamless underwear machine, 75D-72f full-dull polyester DTY is used as the surface yarn, and 50D-24f full-dull polyester FDY and 30D-16f polyester DTY / 20D-PU covering yarn are used as the inner yarn. , No. 1-8 routes of No. 5 yarn feeder: penetrate the surface yarn; No. 1, 3, 5, and 7 routes of No. 2 yarn feeder: penetrate the inner yarn 50D-24f full-dull polyester FDY; No. 2, 4, 6, 8 roads: penetrate 30D-16f-PET / 20D-PU semi-dull covering yarn (lining yarn) to get gray cloth, and then put the gray cloth into scouring→drying→intermediate shaping→dyeing→soaping→drying →Water absorption and softening treatment →Drying →Sizing on the garment, according to the design drawing of the garment, the fabric is cut and sewn to obtain the knitted garment of the present invention. The details are shown in Table 1.

Embodiment 2

[0035] Select 100D-36f full-dull polyester DTY as the surface yarn, the covered yarn of 75D-72f full-dull polyester FDY and 50D-24f polyester DTY / 20D-PU as the inner yarn, and all the other are the same as embodiment 1 to obtain the knitted clothes. The details are shown in Table 1.

Embodiment 3

[0037] 100D-36f full-dull polyester DTY is selected as the surface yarn, 75D-72f full-dull polyester FDY and 50D-24f polyester DTY / 20D-PU covering yarn are used as the inner yarn, among which, the first- Route 8: threading surface yarn; No. 1, 3, and 5 routes of No. 2 yarn feeder: threading inner yarn 50D-24f full-dull polyester FDY; No. 2, 4, 6, 8 routes: threading 30D-16f- The semi-dull covering yarn (inner yarn) of PET / 20D-PU obtains gray cloth, and all the other are the same as embodiment 1, obtain knitted clothes of the present invention. The details are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bursting strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com