Throttle grip device that receives driver's throttle operation

A door handle and throttle valve technology, which is used in transportation and packaging, bicycle accessories, bicycle control systems, etc., can solve problems such as the increase in the size of the throttle handle device, and achieve the effect of inhibiting and inhibiting the size increase.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

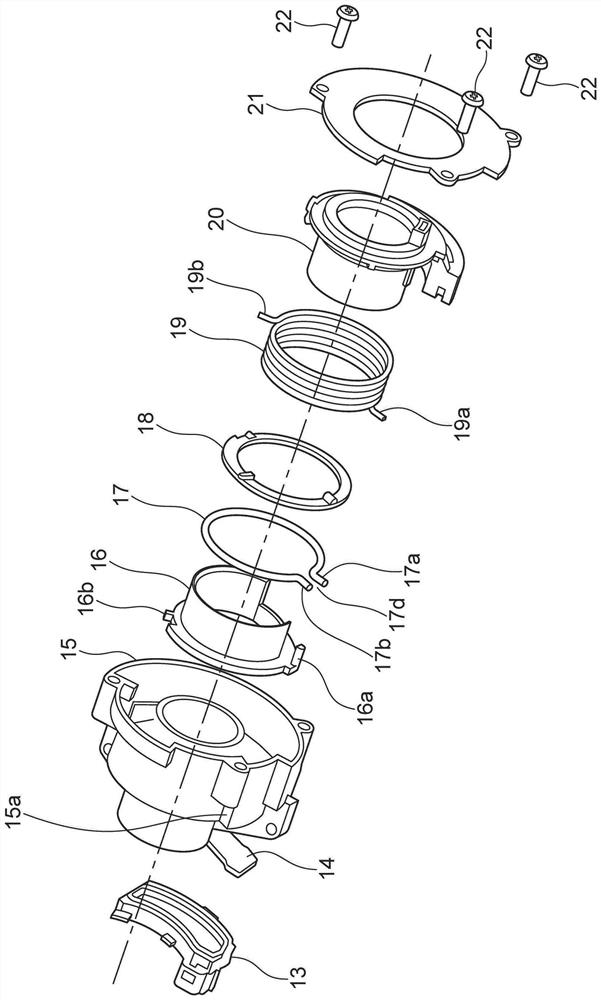

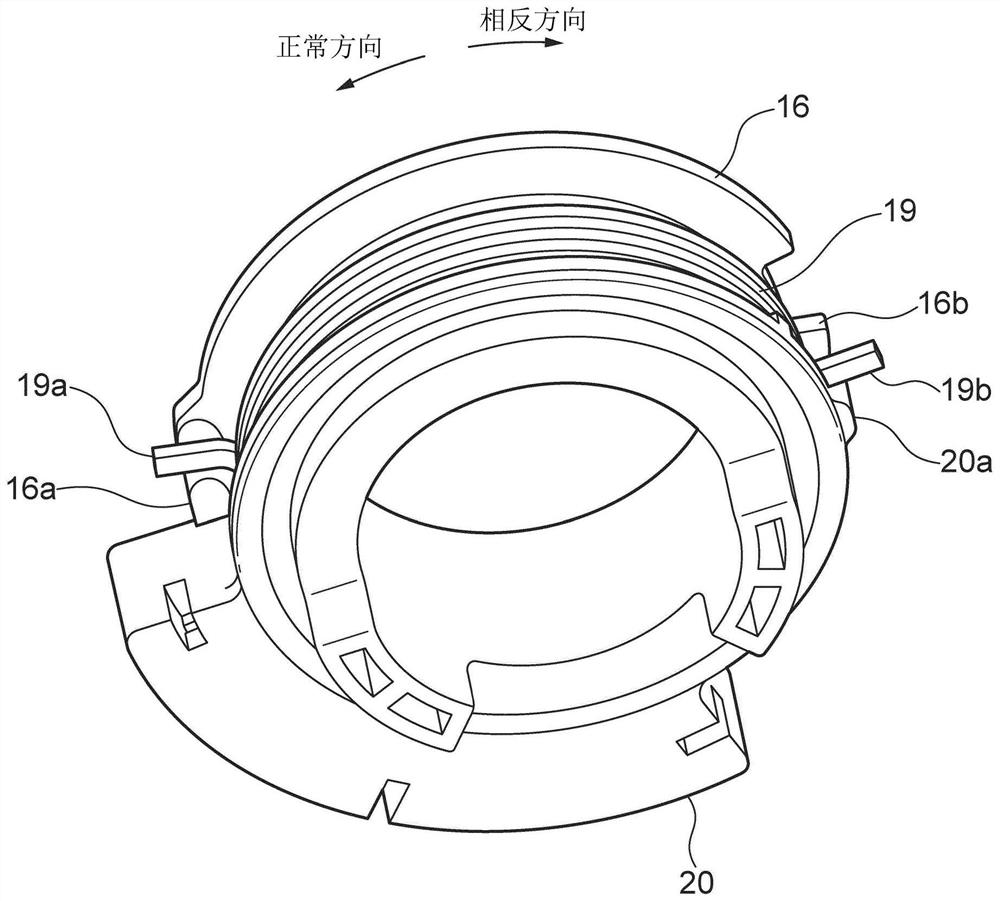

[0020] Hereinafter, embodiments of the present invention will be described in detail with reference to the accompanying drawings.

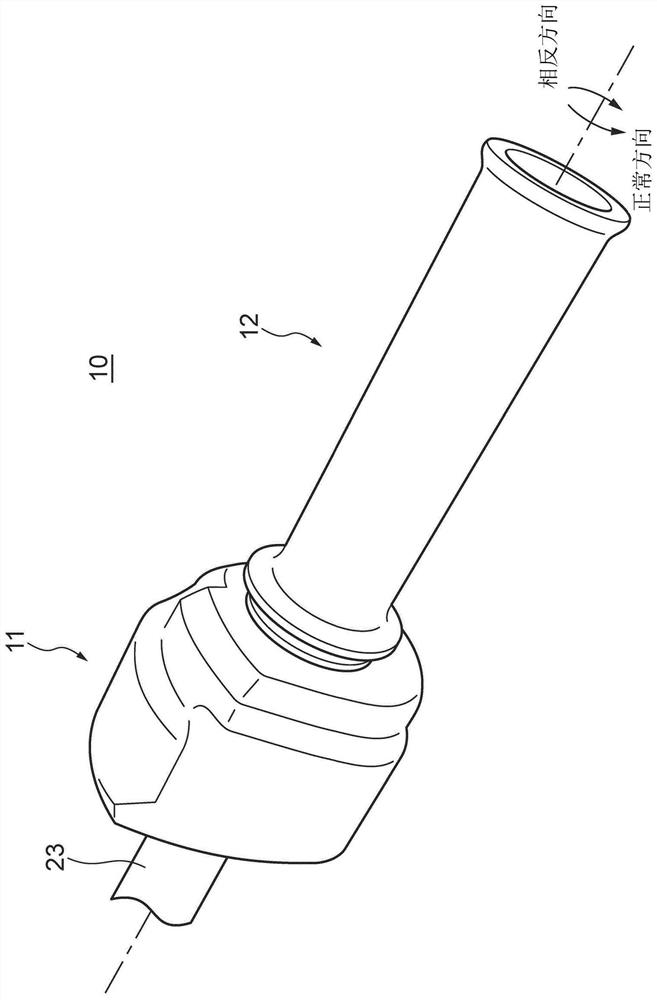

[0021] figure 1 is a perspective view schematically showing the appearance of the throttle handle device 10 according to the present embodiment. exist figure 1 Among them, the throttle handle device 10 includes: a housing 11 attached to a handlebar 23 of the vehicle; and a throttle handle 12 extending from the housing 11 in the axial direction of the handlebar 23 (shown by a broken line in the figure out). The housing 11 includes a rear shell and a front shell, and the handlebar 23 is sandwiched by the rear shell and the front shell. The throttle grip 12 is arranged to be rotatable around the central axis of the handlebar 23 (hereinafter, simply referred to as "around the central axis"), rotatable in a normal direction, which is a direction from an initial position to the driver's side (one direction ), and it is also possible to rotate in the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com