Fuel cell system

A fuel cell system and fuel cell stack technology, which is applied to fuel cells, fuel cell additives, power system fuel cells, etc., can solve the problems of increasing the size of the fuel cell system, and achieve the goal of suppressing the increase in size and supplying efficiently. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

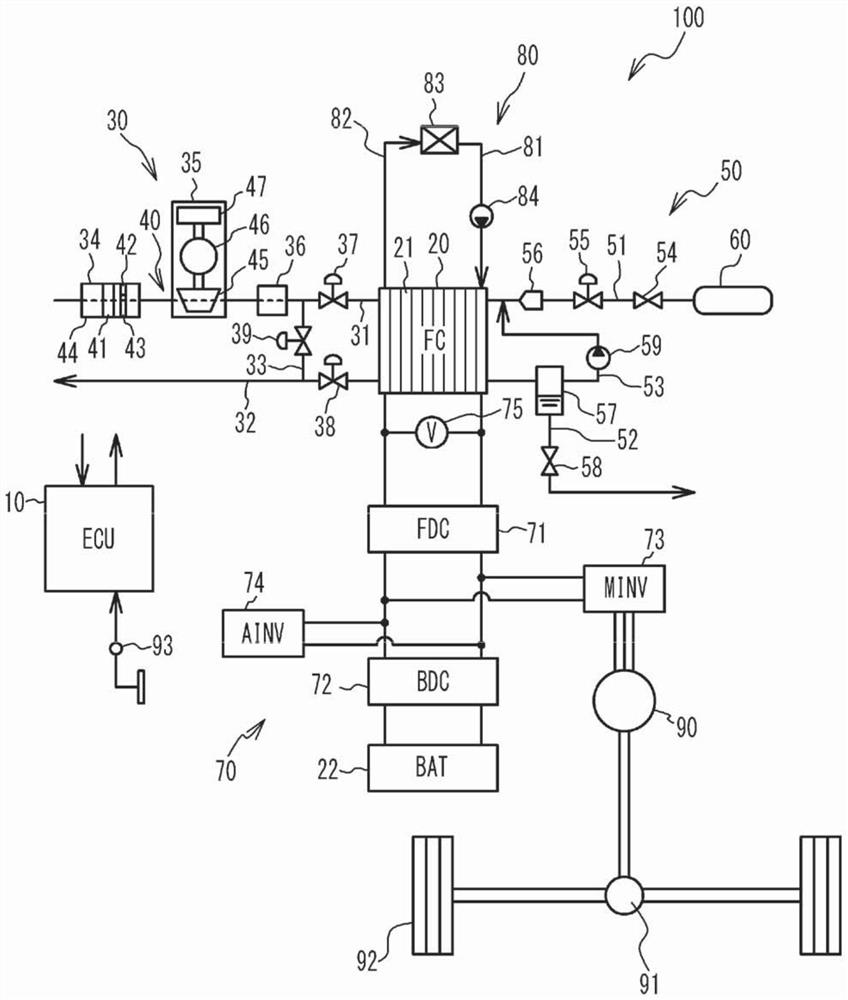

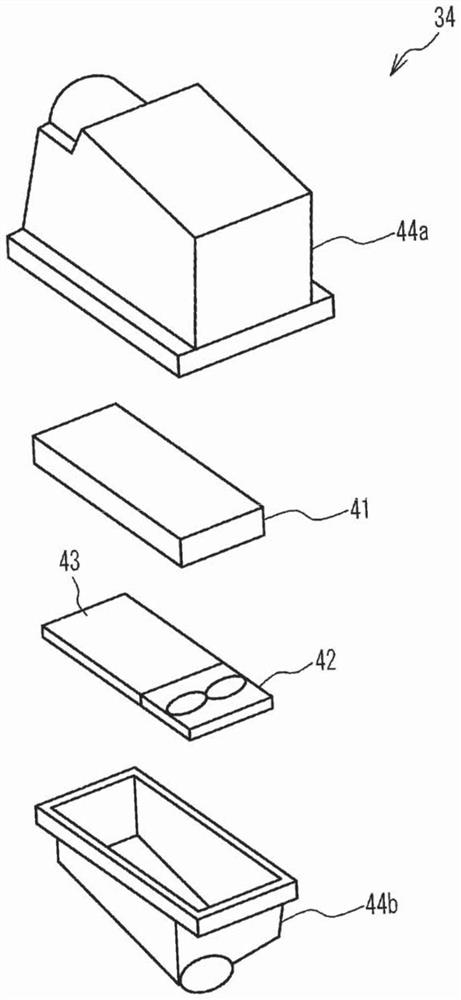

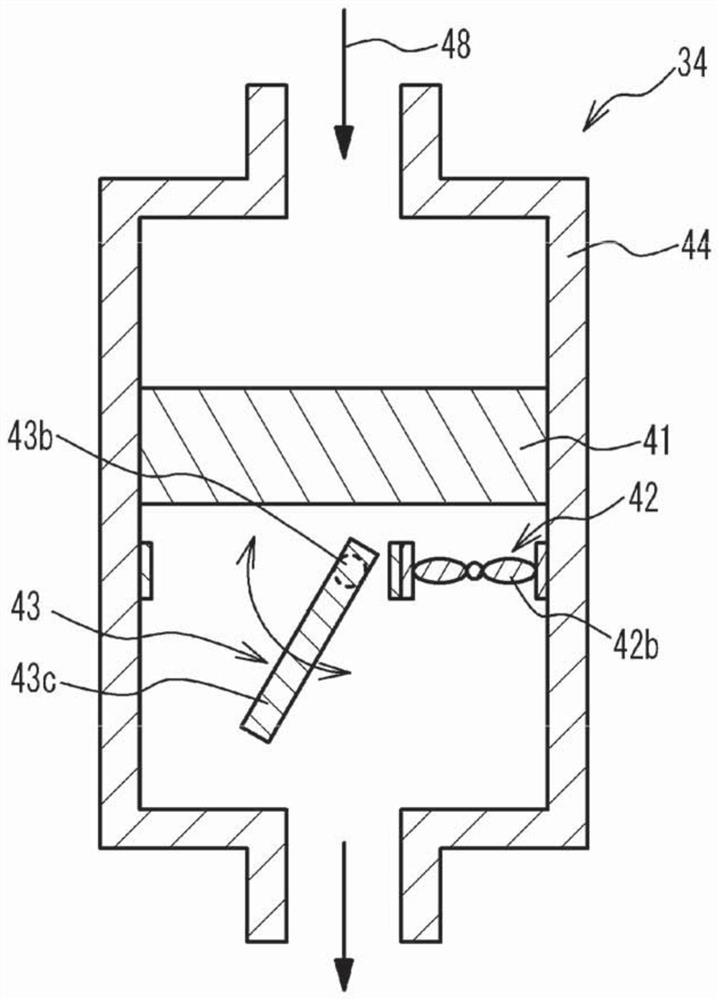

[0032] [Schematic Configuration of Fuel Cell System]

[0033] figure 1 is a schematic diagram of the fuel cell system according to the first embodiment mounted on a vehicle. refer to figure 1 , the fuel cell system 100 includes an electronic control unit (ECU) 10, a fuel cell stack (hereinafter referred to as FC) 20, a secondary battery (hereinafter referred to as BAT) 22, an oxidant gas system 30, a fuel gas system 50, Power system 70 and cooling system 80 . In addition, the vehicle includes an electric motor 90 for running, a transmission 91 , wheels 92 , and an accelerator opening sensor 93 . The vehicle travels by driving the motor 90 using the FC 20 and the BAT 22 as power sources.

[0034] FC 20 receives fuel gas and oxidant gas to generate electricity. The FC 20 includes a stacked unit cell 21 of solid polymer electrolyte type. The unit cell 21 includes: a membrane electrode assembly which is a power generator in which electrodes are arranged on both surfaces of a...

no. 2 example

[0080] Figure 8 is a schematic diagram of a fuel cell system according to a second embodiment mounted on a vehicle. refer to Figure 8 , in the fuel cell system 200 according to the second embodiment, the air compressor 35 , the air cleaner 34 , and the intercooler 36 are arranged in this order from the upstream side of the flow of the oxidant gas flowing through the air supply pipe 31 . Other components are the same as those in the first embodiment, and thus descriptions thereof are omitted.

[0081] As described above, the first embodiment shows the air compressor 35 disposed at the downstream side of the flow of the oxidant gas with respect to the fan 42 and the switching valve 43 . However, in the second embodiment, the air compressor 35 is provided at the upstream side of the flow of the oxidant gas with respect to the fan 42 and the switching valve 43 . Likewise, in the second embodiment, the on-off valve 43 is opened due to the force generated by driving the air com...

no. 3 example

[0083] The third embodiment differs from the first embodiment in that the on-off valve 43 is a solenoid valve or an electric valve, and the opening and closing of the on-off valve 43 is controlled according to an instruction from the controller 10 . Other components are the same as those in the first embodiment, and thus descriptions thereof are omitted.

[0084] [Intermittent operation control of ECU]

[0085] Figure 9 is a flowchart showing an example of intermittent operation control of the ECU in the third embodiment. and Figure 5 Similar to the control shown in the first embodiment, Figure 9 The control shown in starts with the power generation operation in which the required power of the FC 20 is higher than the predetermined power and the FC 20 performs power generation. refer to Figure 9 , the ECU 10 executes with Figure 5 Steps S10 and S12 in the first embodiment are the same as steps S40 and S42. After step S42, the ECU 10 instructs the on-off valve 43 to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com