Linear sliding rail structure capable of being modularized

A linear slide, modular technology, applied in the direction of linear motion bearings, shafts and bearings, bearings, etc., can solve the problems of insufficient rigidity of aluminum alloy sliders, heavy overall weight, space occupation, etc., to achieve disassembly and disassembly Convenient and fast, easy and convenient to assemble, easy to assemble and disassemble

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

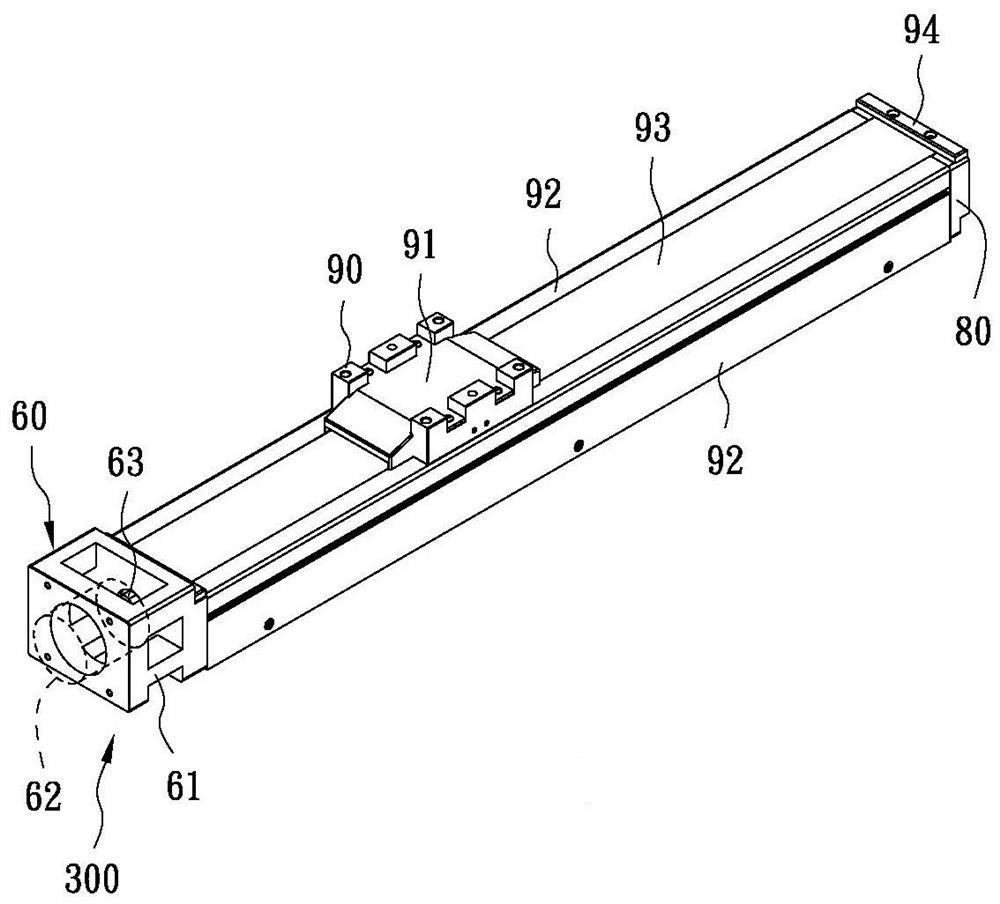

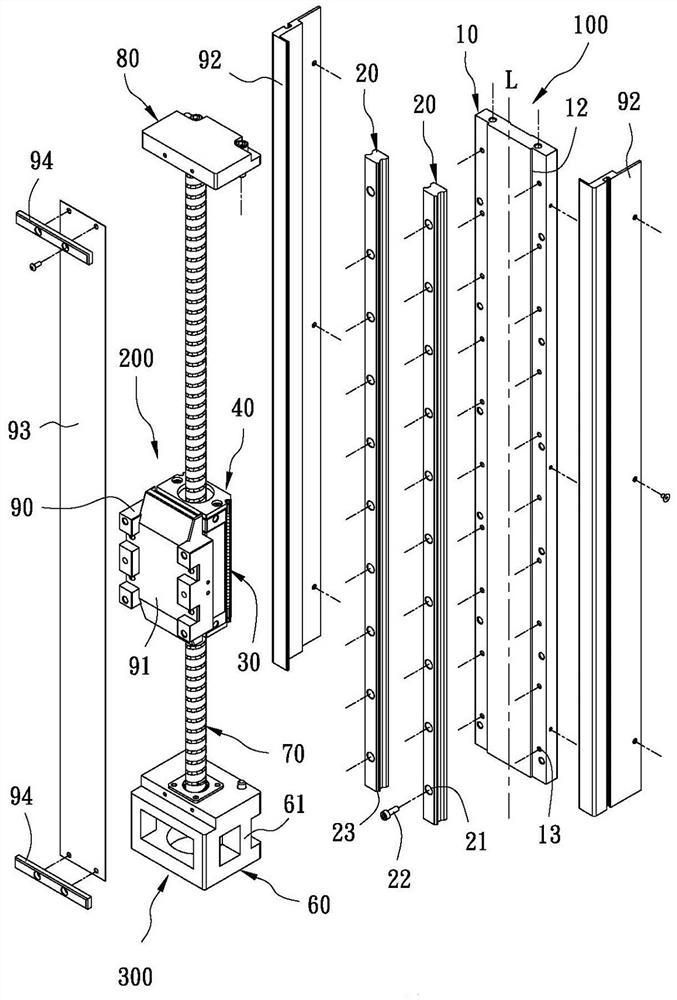

[0042] refer to figure 1 and figure 2 , a preferred embodiment of the modular linear slide rail structure of the present invention includes a slide rail unit 100 , a slider unit 200 and a drive unit 300 .

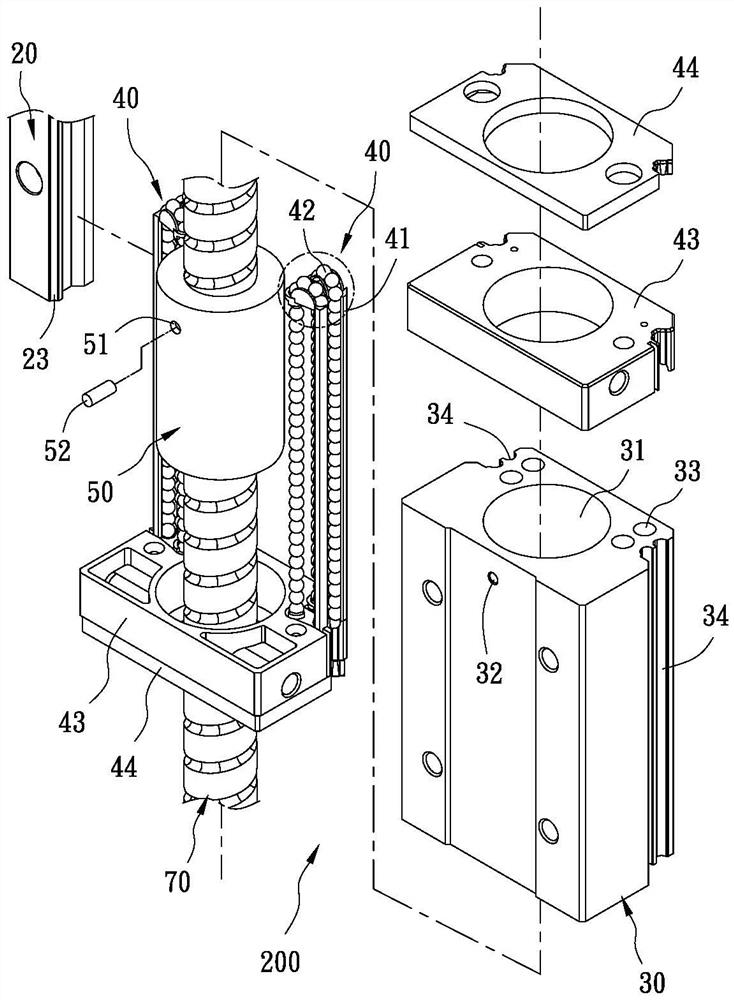

[0043] refer to figure 2 and Figure 4 , the slide rail unit 100 has a slide rail base 10 and two slideway seats 20 extending along a major axis direction L, the slideway seats 20 are assembled on both sides of the slide rail base 10, and are connected with the slide rail base 10 The rail base 10 establishes a sliding channel 11 .

[0044] The two sides of the long axis direction L of the slide rail base 10 are respectively provided with a restricting portion 12, the restricting portion 12 is a downwardly recessed stepped channel, so that the lower edge of the slide seat 20 can be abutted and accurately embedded in the slide rail base 10. On the restricting portion 12 , to ensure that the slideway seats 20 can be kept parallel to each other on the slide rail base 10 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com