Clutch control mechanism and vehicle

A clutch control and release bearing technology, applied in clutches, electric clutches, mechanical drive clutches, etc., can solve the problems of skew of the lever actuator, uneven force on the clutch and release bearing, etc., to avoid skew, easy space layout, Uniform force effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

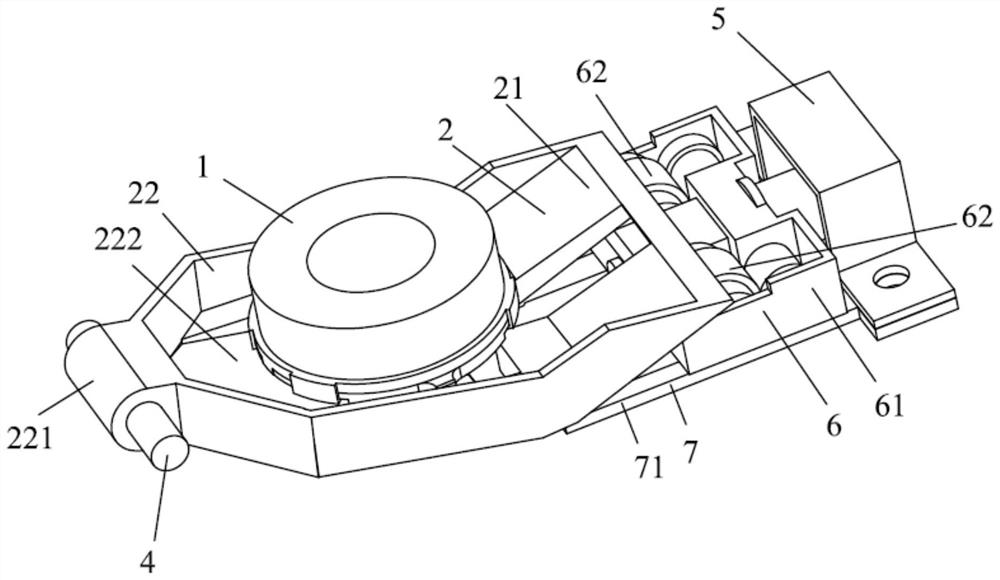

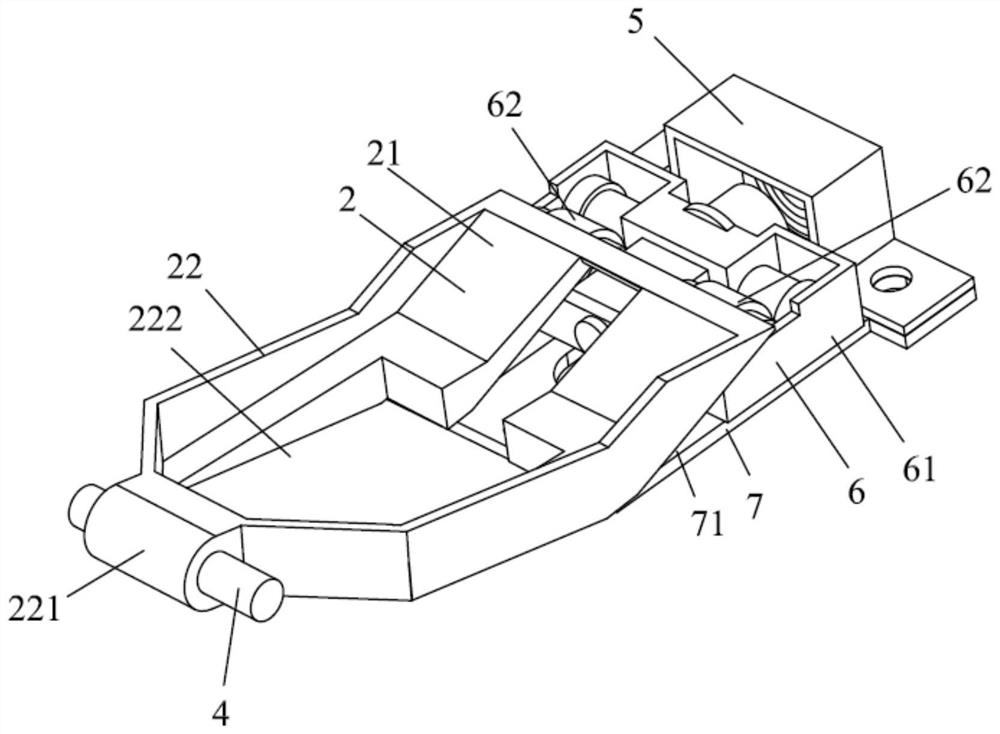

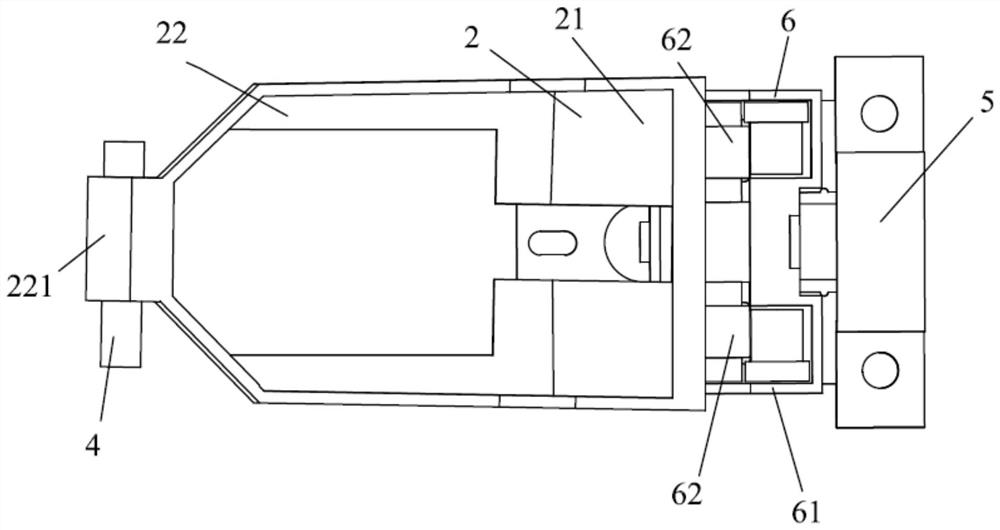

[0052] Such as Figure 1 to Figure 9 As shown, the first embodiment of the present invention provides a clutch control mechanism, including a release bearing 1, an actuator frame 2 and a driving device. The actuator frame 2 includes a rolling plate 21 and a support frame 22 for placing and supporting the release bearing 1, the first end of the support frame 22 is connected to the rolling plate 21 (fixedly connected or integrally formed), The second end of the support frame 22 is rotatably connected to the transmission case through the support pin shaft 4 . The driving device applies a driving force to the actuator frame to make the actuator frame 2 swing around the axis of the support pin shaft 4, thereby pushing the release bearing 1 to move toward or away from the clutch, so as to control the clutch joining or disengaging.

[0053] In the first embodiment, the rolling plate end of the actuator frame 2 is a rolling plate 21 .

[0054] In some alternative solutions, the rol...

no. 2 example

[0088] Figure 10 The clutch control mechanism provided for the second embodiment of the present invention is different from the first embodiment in that the second end of the raceway extends below the bottom surface of the support frame 22, and the rolling member 62 is in the position When the first end of the raceway is in contact with the highest point of the bottom surface of the rolling plate 21, the rolling member 62 is in contact with the bottom surface of the support frame 22 when it is in the second end of the raceway. The bottom surface of the support frame 22 and the bottom surface of the rolling plate 21 transition through an arc. When the rolling element 62 moves to the inflection point, the speed of the rolling element 62 remains stable, the motor is controllable (providing appropriate driving force), and the clutch is kept engaged.

[0089] The arc surface protrudes toward the biasing direction of the rolling element 62 . The angle between the bottom surface o...

no. 3 example

[0095] Figure 11 to Figure 15 Shown is the clutch control mechanism provided by the third embodiment of the present invention, which differs from the first embodiment in that:

[0096] (1) The support element is an arc-shaped bump 30, which is integrally formed on the top surface of the support frame 22, and the side surfaces other than the top surface of the arc-shaped bump 30 are limited. position hole 301, the claw portion 91 of the release bearing bottom plate 9 is provided with a mounting hole 92, and the clutch control mechanism also includes a snap spring 40 clamped between the release bearing bottom plate 9 and the release bearing 1, the clip The locking feet of the spring 40 are inserted into the installation hole 92 and the limiting hole 301 to limit the displacement of the release bearing bottom plate 9 and the release bearing 1 outside the axial direction. That is, the release bearing base plate 9 and the release bearing 1 cannot rotate around the guide shaft 8 ....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com