High-temperature-resistant, safe and explosion-proof quick-opening blind plate structure

A high temperature resistant and explosion-proof technology, used in safety valves, functional valve types, lift valves, etc., can solve problems such as nowhere to release pressure, equipment safety hazards, damage to sealing rings, etc., to prevent leakage, improve safety, The effect of improving the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

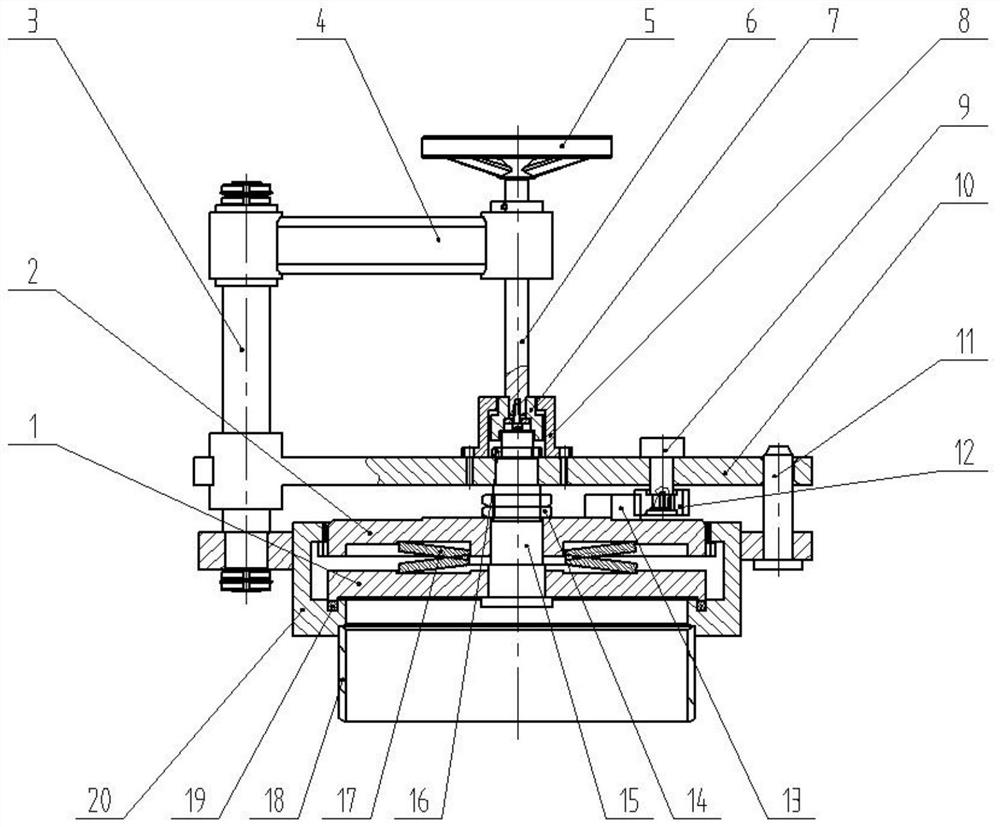

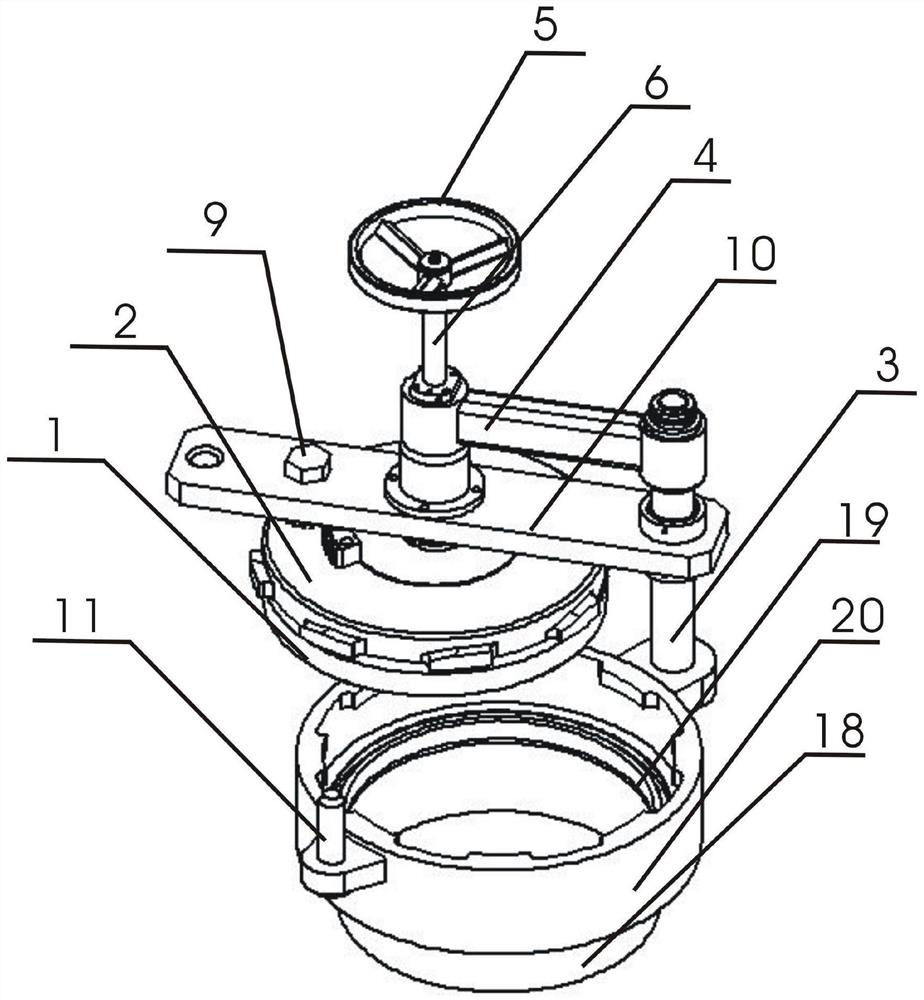

[0024] The invention provides a high-temperature-resistant, safe and explosion-proof quick-opening blind plate structure, including a quick-opening blind plate body 1, a gland 2, a rotating shaft 3, a rotating arm 4, a handwheel 5, a lead screw 6, a connector 7, and an end cover 8. Gear shaft 9, positioning plate 10, guide shaft 11, pinion 12, large gear 13, large lock nut 14, mandrel 15, disc spring 17, cylinder 18, graphite sealing ring 19, cylinder seat 20, hand The lower side of the wheel 5 is connected with the lead screw 6, the lead screw 6 is set on one end of the shaft arm, the other end of the shaft arm is set on the rotating shaft 3, the lower side of the rotating shaft 3 passes through the installation groove on the side of the cylinder seat 20 and is fixed by a nut, The lower end of the lead screw 6 is connected to the connector 7, the connector 7 is installed inside the end cover 8, the end cover 8 is fixed on the positioning plate 10 by bolts, one end of the posit...

Embodiment 2

[0026] When the quick opening blind plate needs to be closed, turn the hand wheel 5, the hand wheel 5 drives the screw 6 to rotate downward, and the positioning plate 10, the gland 2, and the quick opening blind plate 1 move downward along the rotating shaft 3 through the connector 7 , until the positioning hole of the positioning plate 10 penetrates the guide shaft 11, the quick opening blind plate body 1 is pressed against the graphite sealing ring 19, stop turning the handwheel 5 at this time, and then use a torque wrench to turn the gear shaft 9, the gear shaft 9 drives the small The gear 12 rotates, so that the small gear 12 drives the large gear 13 and the gland 2 to rotate around the mandrel 15 together. At this time, the inclined surface of the boss of the outer ring of the gland 2 and the cylinder seat 20 generate axial thrust along the boss, and the disc spring 17 Push the quick-opening blind plate body 1 to compress the graphite sealing ring 19 in the axial direction...

Embodiment 3

[0028] When opening the quick-opening blind plate: first turn the gear shaft 9 with a torque wrench, so that the small gear 12 drives the large gear 13 and the gland 2 to rotate around the mandrel 15 until the boss of the outer ring of the gland 2 and the upper edge of the cylinder seat 20 The bosses are completely staggered. At this time, turn the hand wheel 5 to drive the screw 6 and move the positioning plate 10, the gland 2, and the quick-opening blind plate 1 upwards along the rotating shaft 3 through the connector 7. When moving to the bottom plane of the quick-opening blind plate 1 When it is higher than the upper plane of the cylinder seat 20, the rotating arm 4 can be rotated along the rotating shaft 3, so that the quick-opening blind plate 1 can be opened to a suitable position such as figure 2 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com