Device and method for testing coal dust explosion propagation characteristics of mine with corner joint structure

A technology for explosion propagation and characteristic testing, which is applied in the field of safety technology and engineering, and can solve the problems such as the rare research and development of coal dust explosion devices with angle-connected structures, the difficulty in researching the mechanism of coal dust explosion propagation characteristics, and the lack of a channel structure. Simulate the effect of dust production, simple structure and increased cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

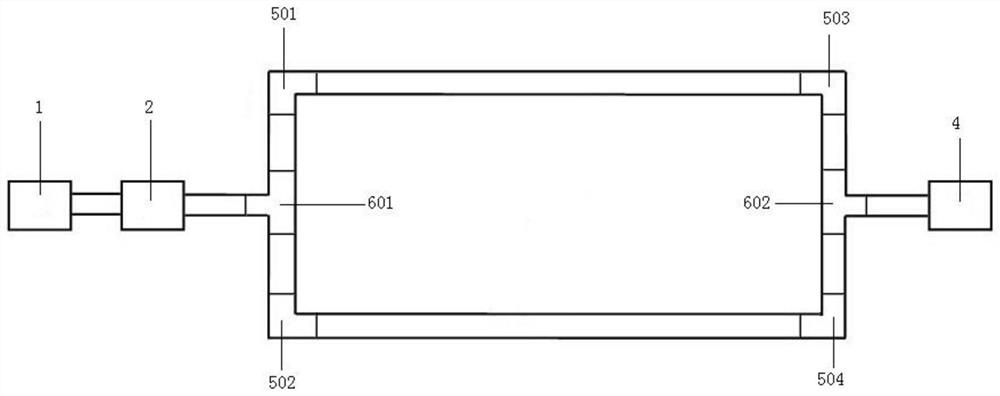

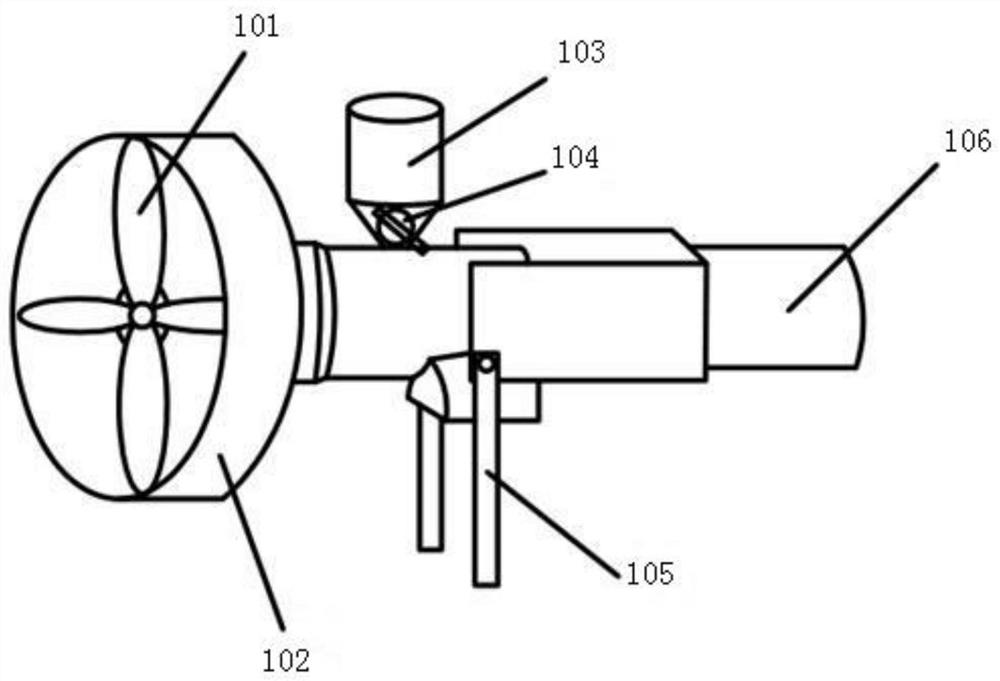

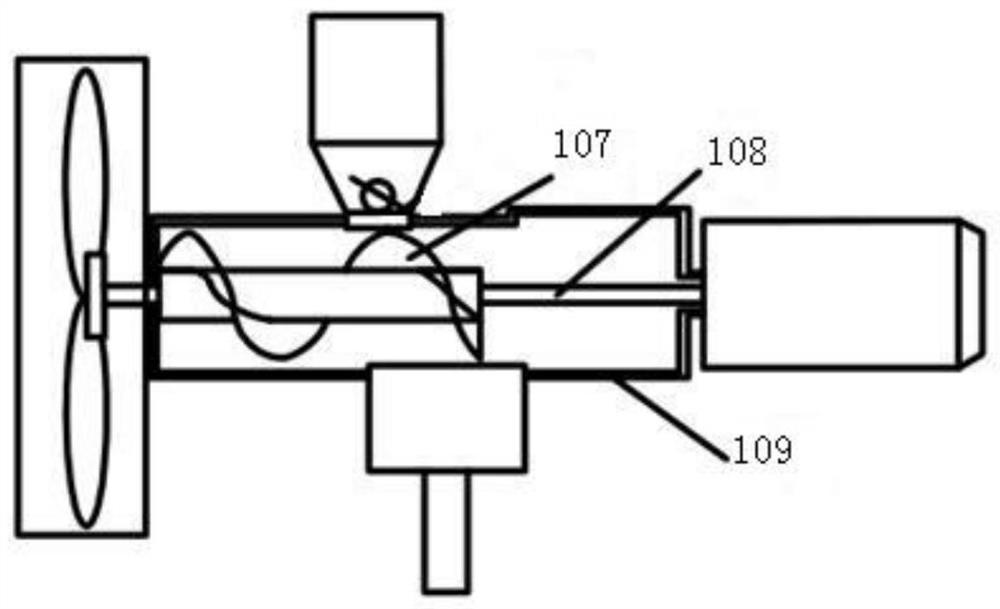

[0031] like Figure 1 to Figure 5As shown, a mine coal dust explosion propagation characteristic testing device with angle connection structure includes a coal dust injection device 1, an ignition device 2, a pipe body purging device 4, an elbow joint and a bifurcated pipe joint, and the coal dust injection device 1 Connect one end of the pipe body through a flange, and the other end of the pipe body is connected to the first joint of the bifurcated pipe joint I601 through the flange, and a point is installed on the pipe body between the bifurcated pipe joint I601 and the coal dust injection device 1 Fire device 2, the second joint and the third joint of the bifurcated pipe joint I601 are respectively connected to one end of the elbow joint I501 and the elbow joint II502 through the pipe body and the flange plate, and the other end is respectively connected to the pipe body and the flange plate respectively. Elbow joint III503 and elbow joint IV504 are connected at one end, an...

Embodiment 2

[0040] like Image 6 As shown, the difference between embodiment 2 and embodiment 1 is that, in embodiment 2, an angle joint branch pipe 3 is arranged between the two intermediate pipe bodies, and the angle joint branch pipe 3 is fixed by the bracket guide rail to reduce the explosion caused by explosion. The tube vibrates. The corner joint branch pipe 3 can be used to lay deposited coal dust. After the explosion propagates to the corner joint branch, a secondary explosion may be formed. The quality, thickness, particle size, and spreading position of the deposited coal dust can be changed according to the test conditions.

[0041] A test method for a test device for the propagation characteristics of mine coal dust explosion with an angle connection structure, comprising the following steps:

[0042] Step 1, add the coal dust required for the test in the coal dust feed box 103 of the coal dust injection device 1; after starting the coal dust injection device 1, the motor 106...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com