Spinning steam generating device with self-cleaning function for spinning production and use method of spinning steam generating device

A steam generating device and self-cleaning technology, applied in the field of textiles, can solve the problems of difficult to handle scale, difficult to clean the inner wall of the generator, and power consumption, so as to achieve centralized collection and treatment, improve cleaning effect, improve cleaning effect and clean The effect of the degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] In order to make the technical problems, technical solutions and advantages to be solved by the present invention clearer, the following will describe in detail with reference to the drawings and specific embodiments.

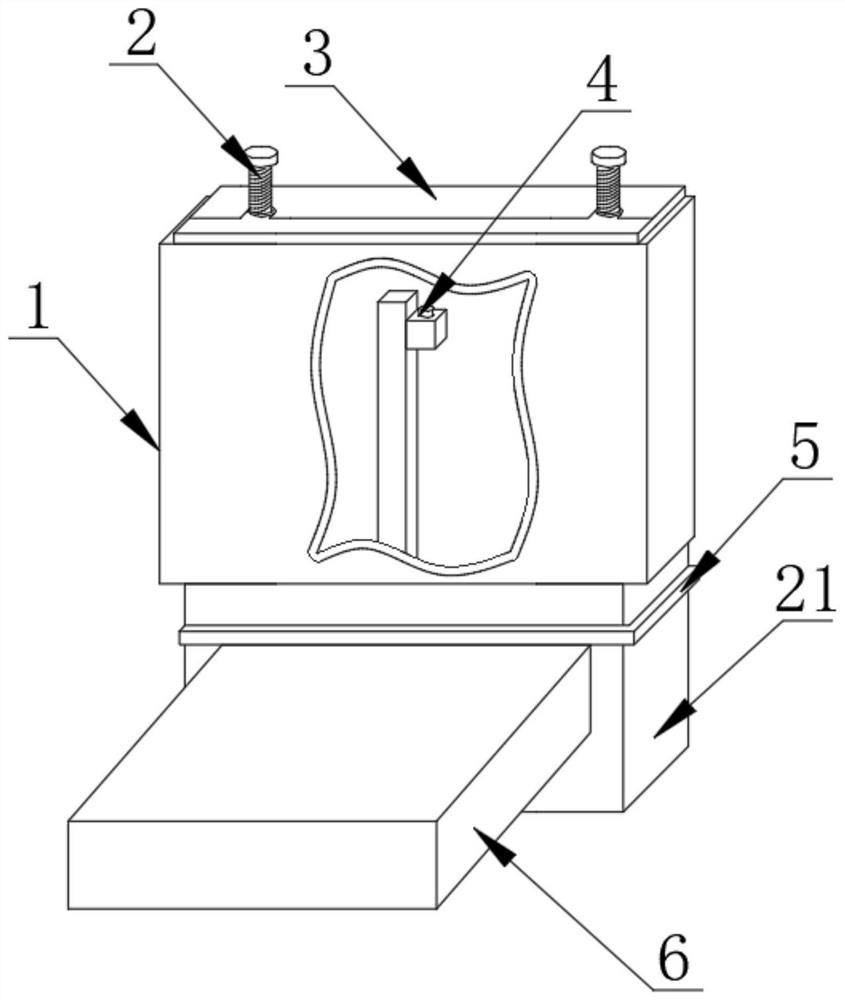

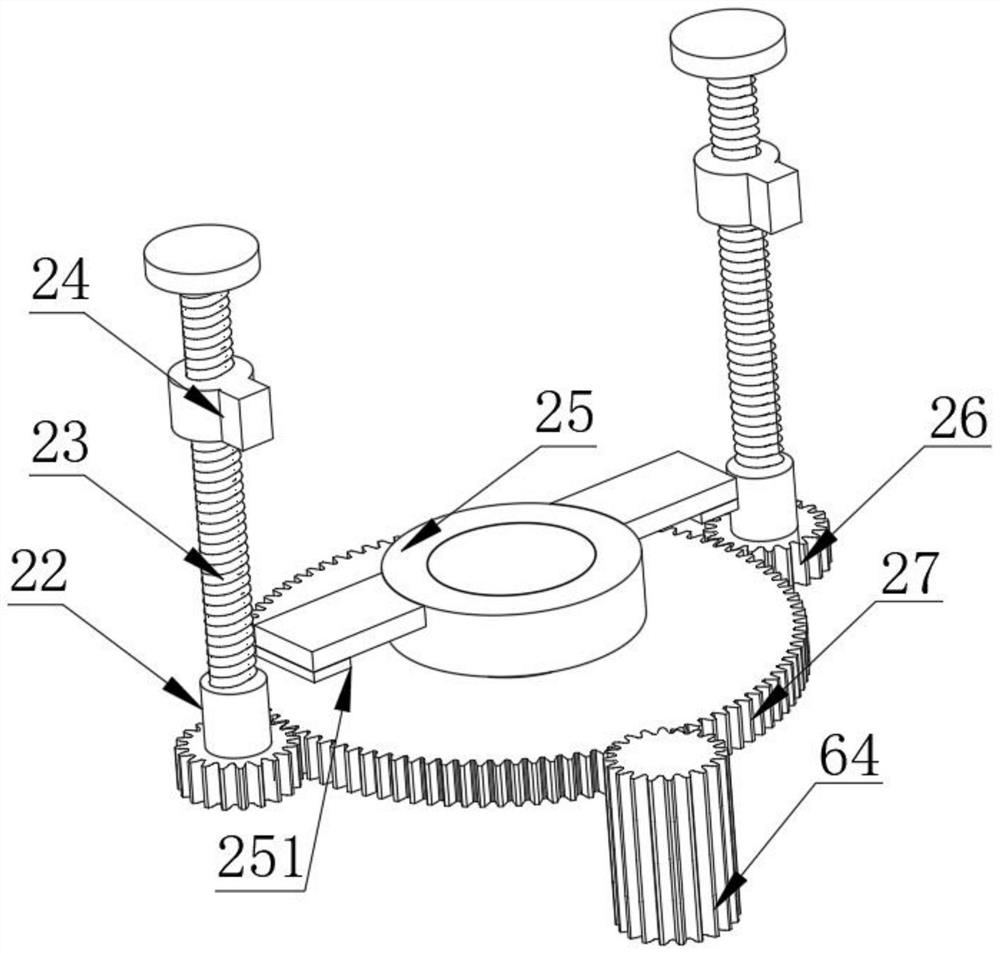

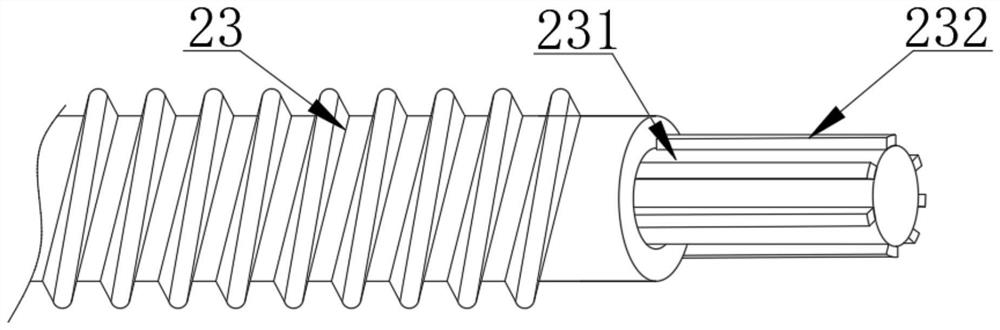

[0036] as attached figure 1 to attach Figure 7 Embodiments of the present invention provide a textile steam generating device with self-cleaning function for textile production and its use method, comprising a steam generating box 1, a water level sensor 4 is fixedly installed on the inner side of the steam generating box 1, and a bottom surface of the steam generating box 1 A scale cleaning mechanism 2 is fixedly installed, a scale collecting mechanism 5 is detachably installed on the outside of the steam generating box 1, and a heat energy conversion mechanism 6 is fixedly installed on the outer wall of the steam generating box 1, and the scale cleaning mechanism 2 and the heat energy conversion mechanism 6 are connected by transmission;

[0037] In ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com