Automatic winding mechanism of mechanical watch and mechanical watch

A mechanical watch, automatic technology, applied in the direction of automatic winding, mechanically driven clock, spring ratchet mechanism, etc., can solve the problems of increasing the thickness of the automatic upper splint, affecting the thickness of the movement, and reducing the thickness of the movement. , The effect of improving installation accuracy and reducing thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0025] In order to better understand the object, structure, and function of the present invention, the automatic string mechanism and the mechanical watch of a mechanical watch of the present invention will be described in further detail below with reference to the accompanying drawings.

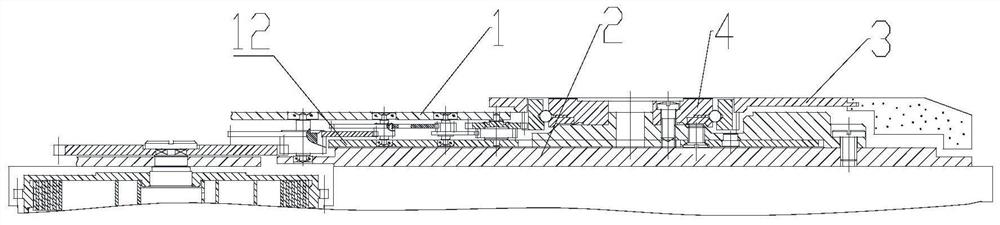

[0026] Such as Figure 1 - Figure 2 As shown, the drive wheel of the conventional automatic upper condition is fixed between the automatic upper splint 1 and the automatic lower clamp 12, and a portion is fixed between the main secting 2 and the automatic upper splint 1, which not only increases the thickness of the entire automatic string portion, but also Since the drive wheel is fixed, the impact of the transmission is affected, further affects the transmission accuracy of the automatic upper string portion.

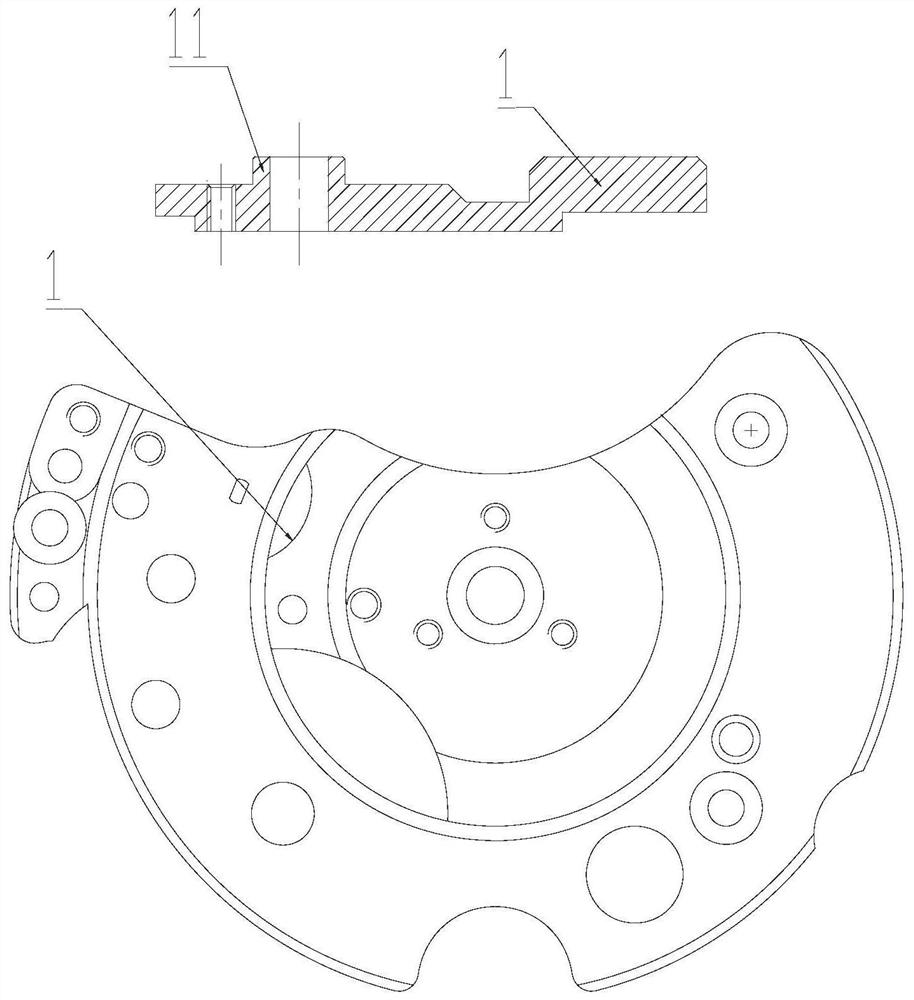

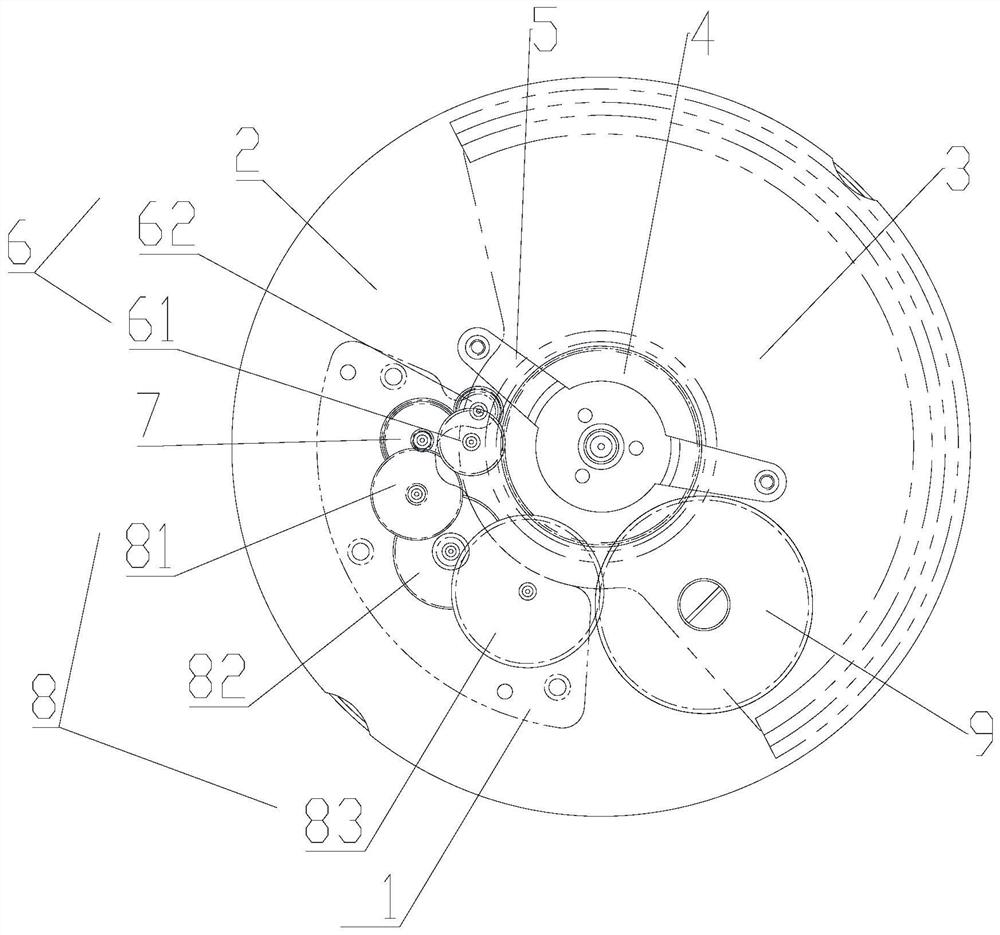

[0027] Such as Figure 3 - Figure 4 As shown, the automatic string mechanism of the mechanical watch of the present invention includes an automatic upper splint 1, a main segment 2, a au...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap