Gravity sensing material management cabinet and method

A technology of gravity sensing and management cabinets, which is applied in the field of material management, can solve the problems of high environmental requirements for material and equipment storage, easy to be affected by temperature and humidity, and non-relevant staff who take it and use it, and achieve a wide range of application prospects and structure. Simple, reliable design principles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

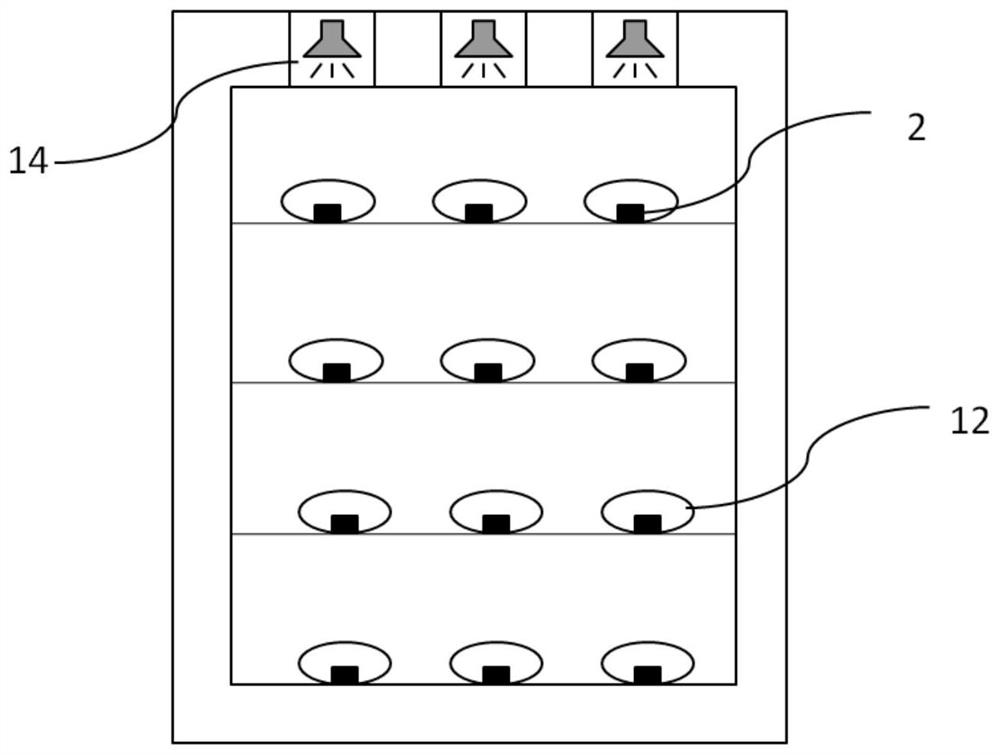

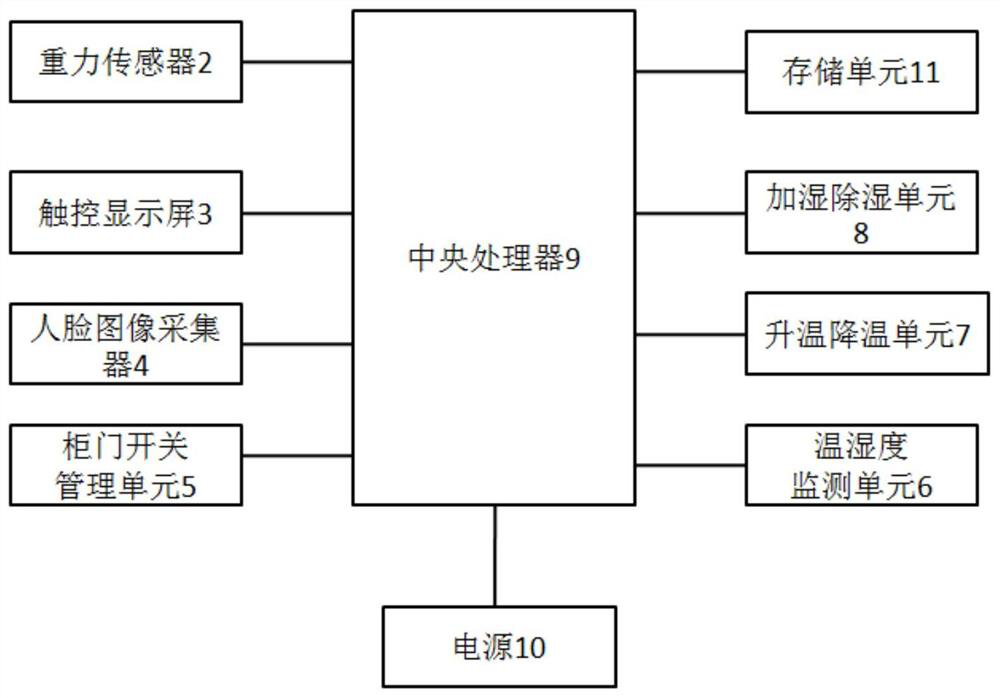

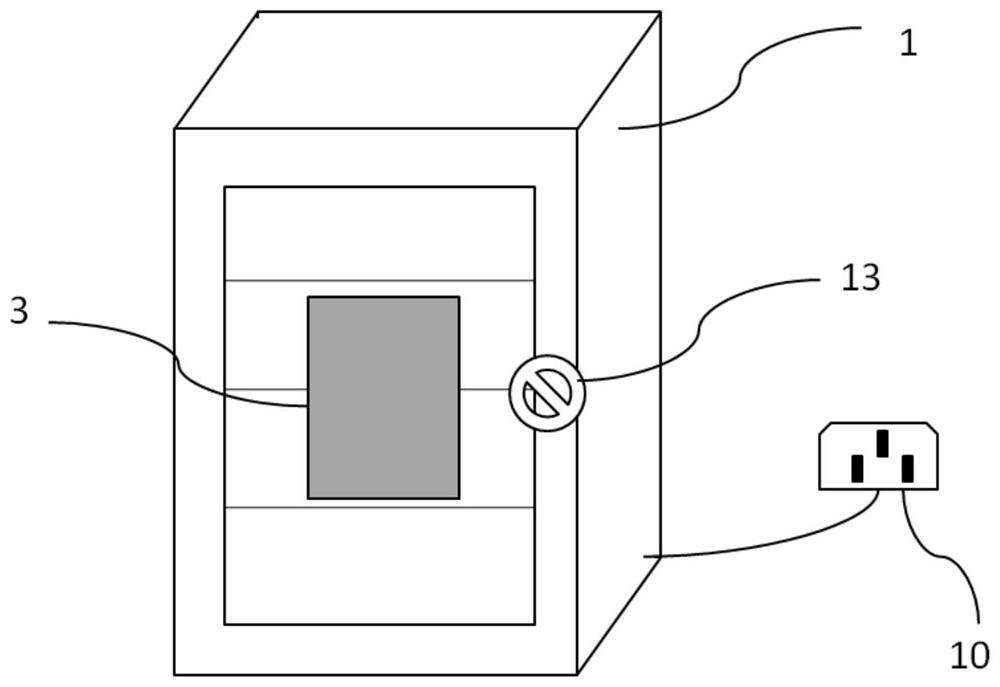

[0036] like figure 1 , figure 2 , image 3 As shown, this embodiment provides a gravity-sensing material management cabinet, including: a management cabinet body 1, a gravity sensor 2, a touch screen 3, a face image collector 4, a cabinet door switch management unit 5, and a temperature and humidity monitoring unit. Unit 6, heating and cooling unit 7, humidification and dehumidification unit 8, central controller 9, power supply 10, storage unit 11; the gravity sensor 2, touch screen 3, temperature and humidity monitoring unit 6, heating and cooling unit 7 and humidification and dehumidification Unit 8, face image collector 4, cabinet door switch management unit 5, storage unit 11 and power supply 10 are all connected to the central controller; multiple interlayers are set in the management cabinet body 1, and multiple interlayers are arranged in each interlayer. A material tray 12, the gravity sensor 2 is arranged on the only matching material tray 12; the management cabin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com