Deep sea mud environment corrosion testing apparatus

A corrosion test and sea mud technology, applied in the direction of measuring devices, weather resistance/light resistance/corrosion resistance, instruments, etc., can solve the problems that cannot truly and completely reflect the corrosion performance of materials, and achieve reliable design principles, simple main structure, and measurement The effect of large sample size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

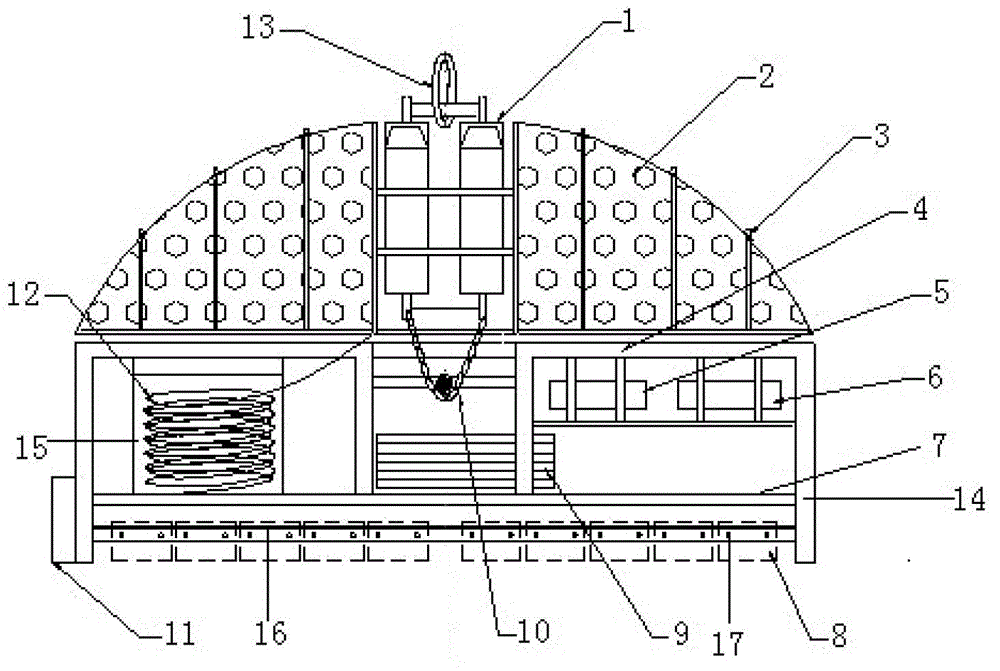

[0011] The main structure of this embodiment includes an acoustic release device 1, a floating body 2, a floating body support 3, a test frame 4, an environmental factor testing device 5, a corrosion testing device 6, a counterweight slideway 7, a sample 8, a counterweight cast iron plate 9, Release anchor chain 10, sea mud sampler 11, recovery cable 12, hoisting ring 13, column 14, insulated metal rod 16, fixing hole 17 and cable bucket 15; the transverse section of the test frame 4 of the cube frame structure is a square, Its side length is 1000-1500mm, and its height is 400mm; the bottom of the test frame 4 is fixed with insulated metal rods 16 in series to form a sample 8; flush, to prevent the sample 8 from being subjected to excessive pressure, and to ensure that the sample 8 is pressed into the sea mud by weight; a circular sea mud sampler 11 is fixedly installed on the outside of one of the four columns 14 for digging Get sea mud and determine sea mud thickness and mak...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com