Rotating table for motorcycle luggage rack welding and welding assembly line

A welding assembly line and luggage rack technology, applied in welding equipment, welding equipment, auxiliary welding equipment, etc., can solve the problems of inconvenient turning over and inconvenient movement of the operation table, and achieve the effect of speeding up work efficiency, saving expenses, and avoiding hoisting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some of the embodiments of the present invention, not all of them.

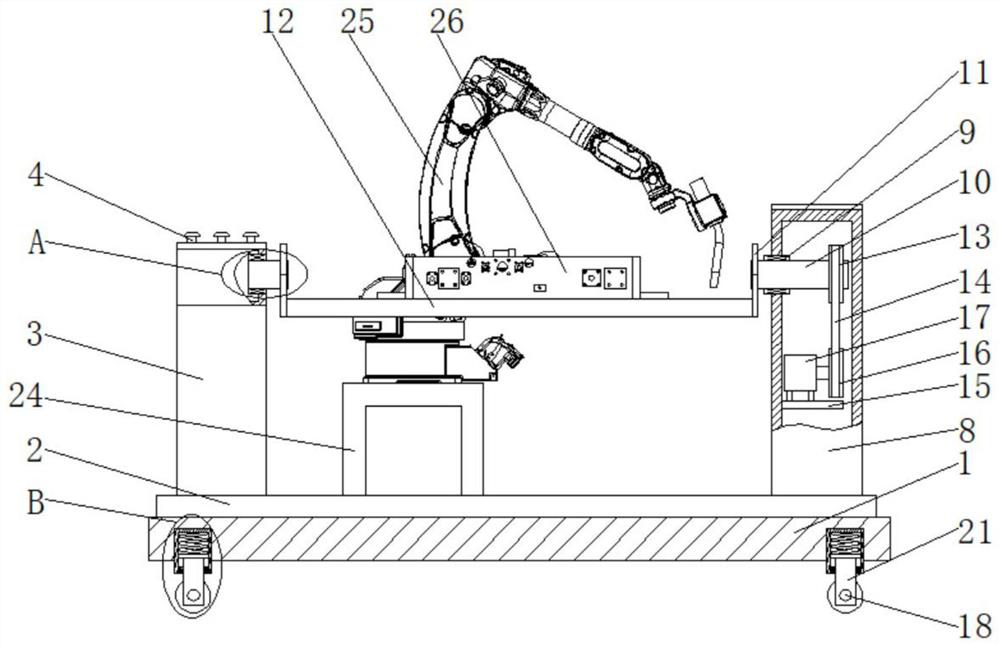

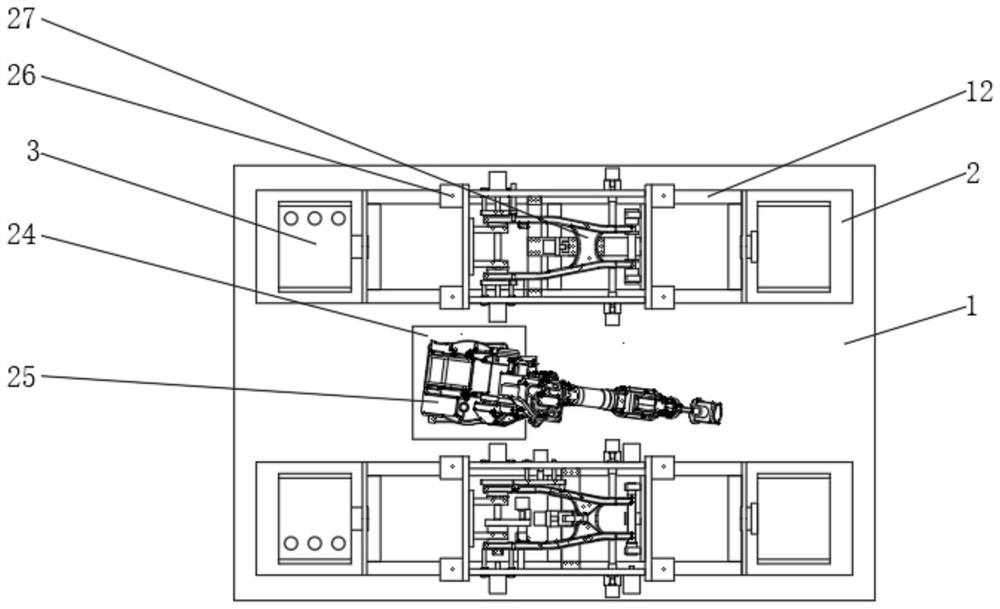

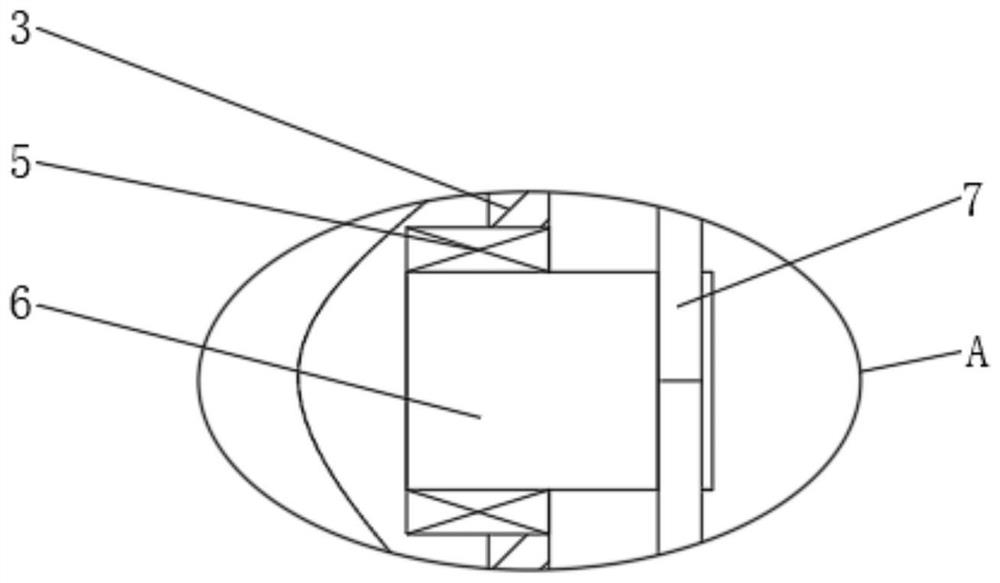

[0020] refer to Figure 1-4 , a rotating table for motorcycle luggage rack welding and a welding line, including a base 1, the upper end of the base 1 is fixedly connected with two symmetrically distributed support plates 2, each support plate 2 is fixedly connected with a control box 3, and the control box 3 Bearing-5 is fixedly sleeved inside, and driven shaft 6 is fixedly sleeved inside of bearing-5, and the end of driven shaft 6 away from bearing-5 is fixedly sleeved with rotating disk-7, and the end of supporting plate 2 is far away from the control box. One end of 3 is fixedly connected with drive box 8, and the inside of drive box 8 is fixedly sl...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap