Combined adjustable supporting device and using method

A supporting device and adjustable technology, applied in the direction of tool storage device, manufacturing tool, etc., can solve the problems of riveting site placement and lack of space, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

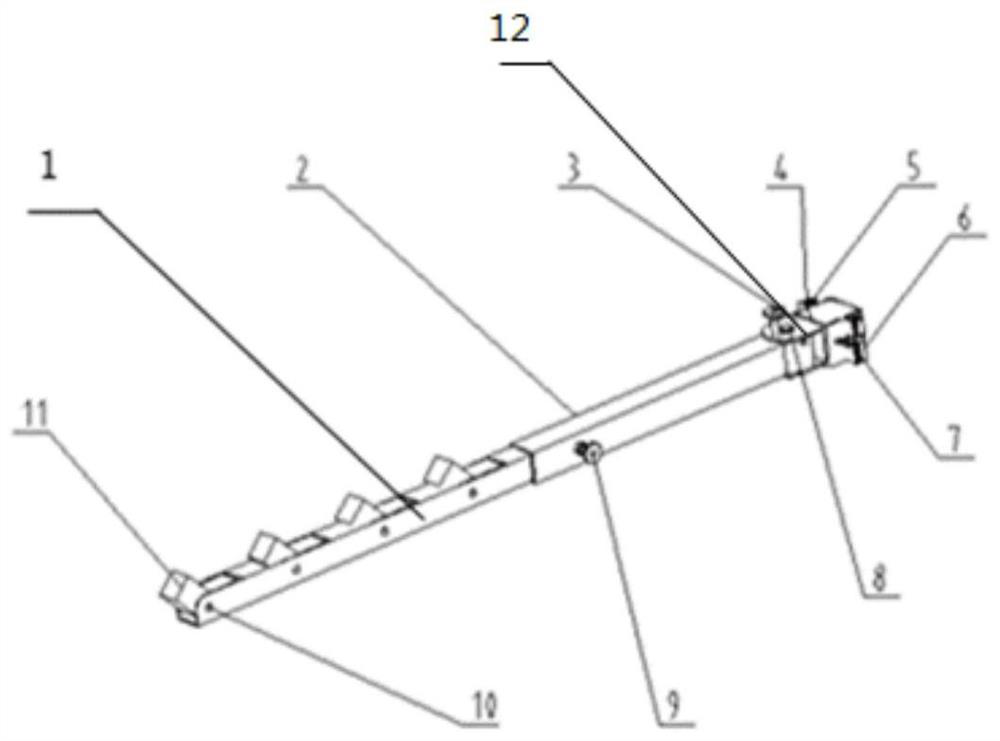

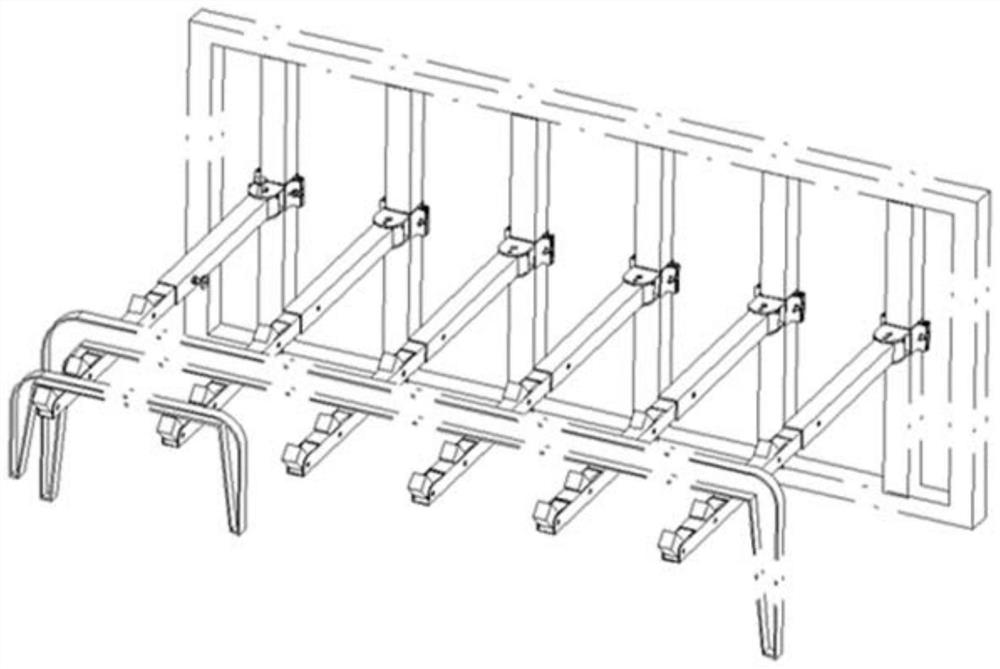

[0032] The combined adjustable support device provided by the present invention and its usage method will be explained below with reference to the accompanying drawings.

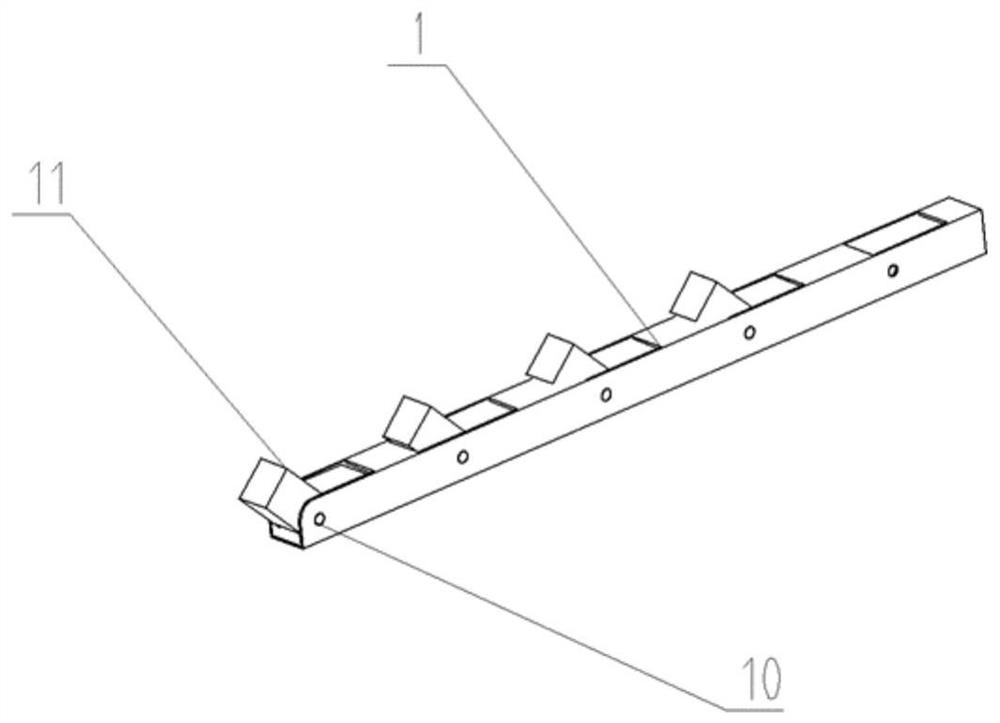

[0033] refer to Figure 1-Figure 6 , the present invention provides a combined adjustable support device, including: positioning telescopic slide rod 1, fixed sleeve assembly 2, rotating support 3, clamping fork lug 4, locking pin 5, sleeve 6, wing nut 7. Rotation pin 8, handle screw 9, fixed pin 10, rotation limit block 11, locking screw 12;

[0034] Wherein, the positioning telescopic slide bar 1 is a hollow square steel pipe, with an equidistant square notch on the top, and fixing pin holes are opened on the side of the notch, and the positioning telescopic slide bar 1 is connected with the rotation limiting block 11 through the fixing pin 10, and the rotation limiting block 11 can rotate in square notch.

[0035] The fixed sleeve assembly 2 has a hollow square steel pipe at the head, a rotating cylinde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com