Assembly type integrated toilet without plate descending

A toilet, prefabricated technology, used in water supply devices, building components, sewage removal, etc., can solve the problems of occupying building plane space, high cost, and complicated dry installation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

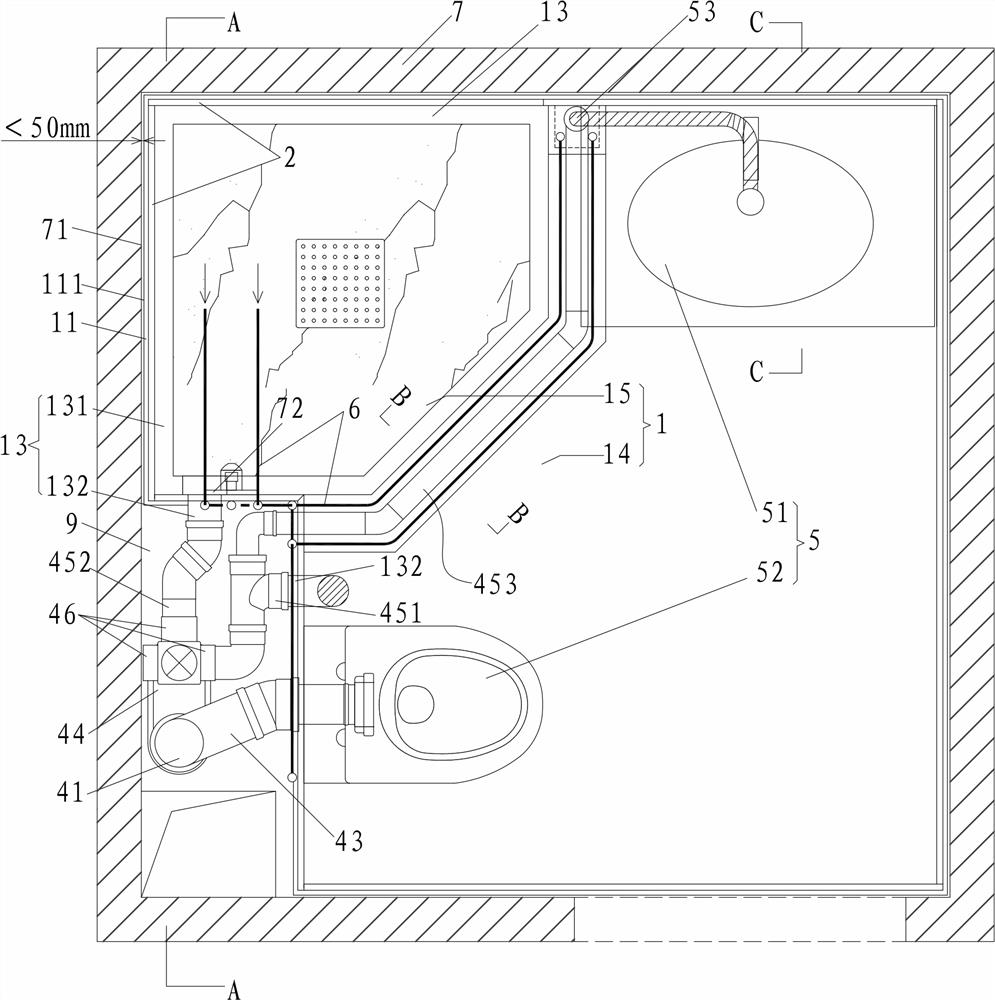

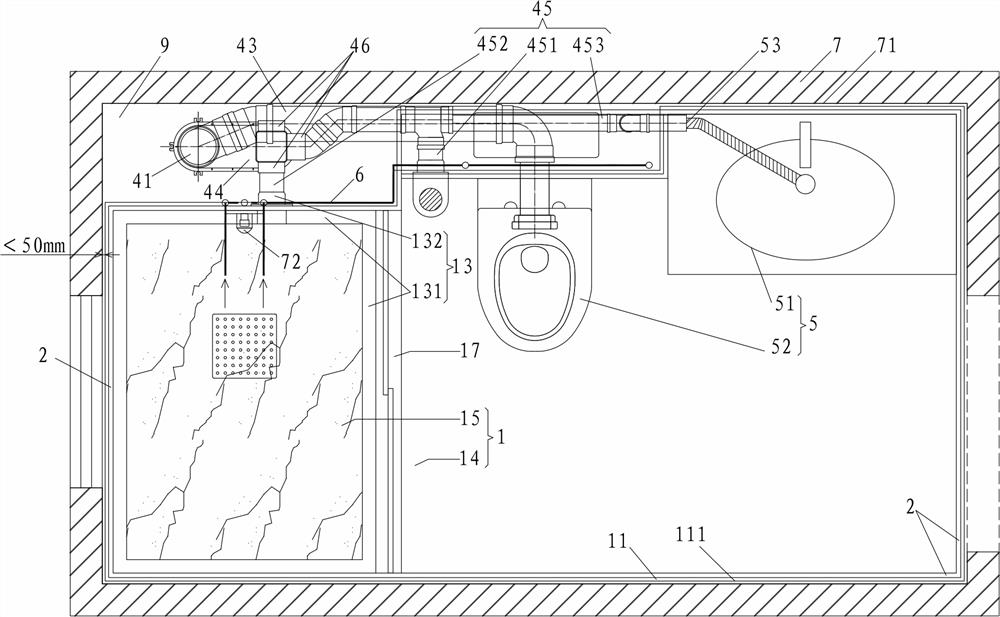

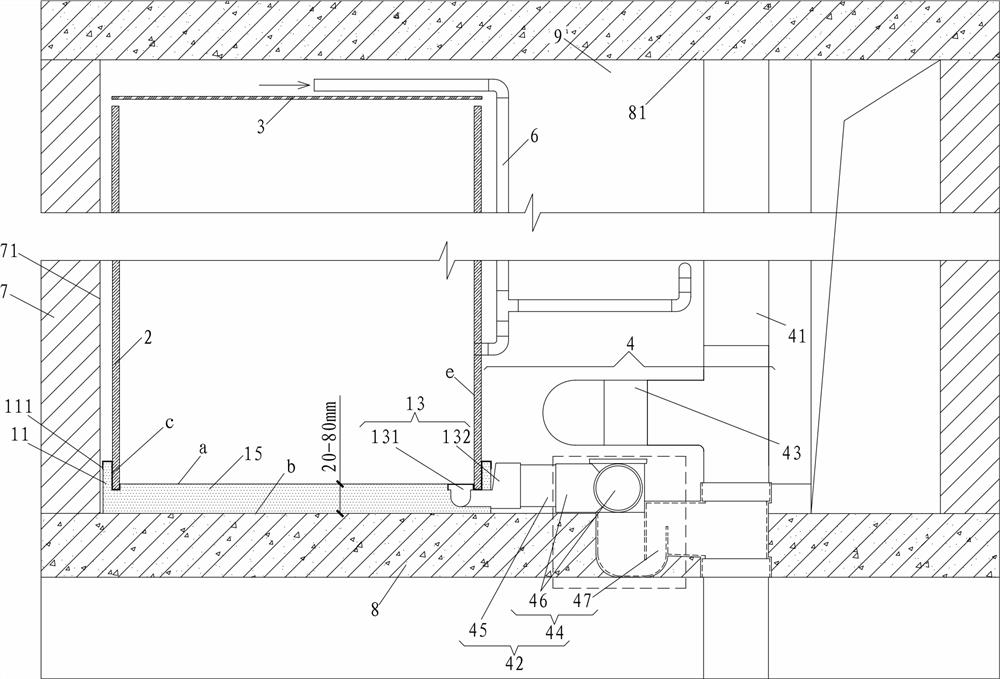

[0029] Such as figure 1 , 2 , 3, the non-falling plate assembled integrated toilet of the present invention is composed of a waterproof chassis 1, a waterproof wall panel 2, a roof 3, a drainage system 4, a drainage device 5, a water supply pipeline 6, a structural wall 7, a structural floor 8, a structural The top surface 81 and the pipeline maintenance shaft 9 are formed; the waterproof chassis 1 is placed above the structural ground 8, the bottom surface b of the waterproof chassis 1 is close to the structural ground 8, and the top surface a of the waterproof chassis 1 is close to the structural ground 8. The height of the surface is 50mm, the top plate 3 is located at the top of the waterproof wall panel 2, the lower part of the structural top surface 81, and the top surface of the top plate 3 is less than 30mm from the bottom surface of the top surface 81; the waterproof chassis 1 is composed of a waterproof baffle 11, a wall The plate slot 12 and the ground drain 13 are...

Embodiment 2

[0031] Such as figure 1 , 2 , 3, the non-falling plate assembled integrated toilet of the present invention is composed of a waterproof chassis 1, a waterproof wall panel 2, a roof 3, a drainage system 4, a drainage device 5, a water supply pipeline 6, a structural wall 7, a structural floor 8, a structural The top surface 81 and the pipeline maintenance shaft 9 are formed; the waterproof chassis 1 is placed above the structural ground 8, the bottom surface b of the waterproof chassis 1 is close to the structural ground 8, and the top surface a of the waterproof chassis 1 is close to the structural ground 8. The height of the surface is 60mm, the top plate 3 is located at the top of the waterproof wall panel 2, the lower part of the structural top surface 81, and the top surface of the top plate 3 is less than 100mm from the bottom surface of the top surface 81; the waterproof chassis 1 is composed of a waterproof baffle 11, a wall The plate slot 12 and the ground drain 13 ar...

Embodiment 3

[0033] Such as figure 1 , 2 As shown in , 4, in the non-falling plate assembled integrated toilet according to the present invention, the waterproof chassis 1 is composed of a dry area chassis 14 and a wet area chassis 15, and there is a gap between the two adjacent chassis that is higher than the top surface a of the waterproof chassis 1 Waterproof isolation strip 16, waterproof isolation strip 16 is covered with 冂 type isolation baffle 17, 冂 type isolation baffle 17 is enclosed within the outside of waterproof isolation baffle 16, and the bottom of 冂 type isolation baffle 17 is lower than in waterproof isolation baffle 16 of heights.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com