Mixer capable of automatically quantifying standard oil sample and used for inspection of the online monitoring device applied to dissolved gas in oil, and standard oil sample configuration method

A technology for dissolving gas in oil and monitoring device, which is applied to mixers with rotary stirring devices, measuring devices, chemical instruments and methods, etc. Large volume and other problems, to achieve the effect of high degree of equipment automation, intuitive human-computer interaction, and improved configuration speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] In order to make the objectives, technical solutions and beneficial effects of the present invention clearer, the technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments It is only some embodiments of the present invention, but not all embodiments.

[0033] In the description of the present invention, it should be understood that the terms "first" and "second" are used for description purposes only, and cannot be interpreted as indicating relative importance or implicitly indicating the quantity of indicated technical features. Thus, a feature defined as "first" or "second" may explicitly or implicitly include one or more of these features.

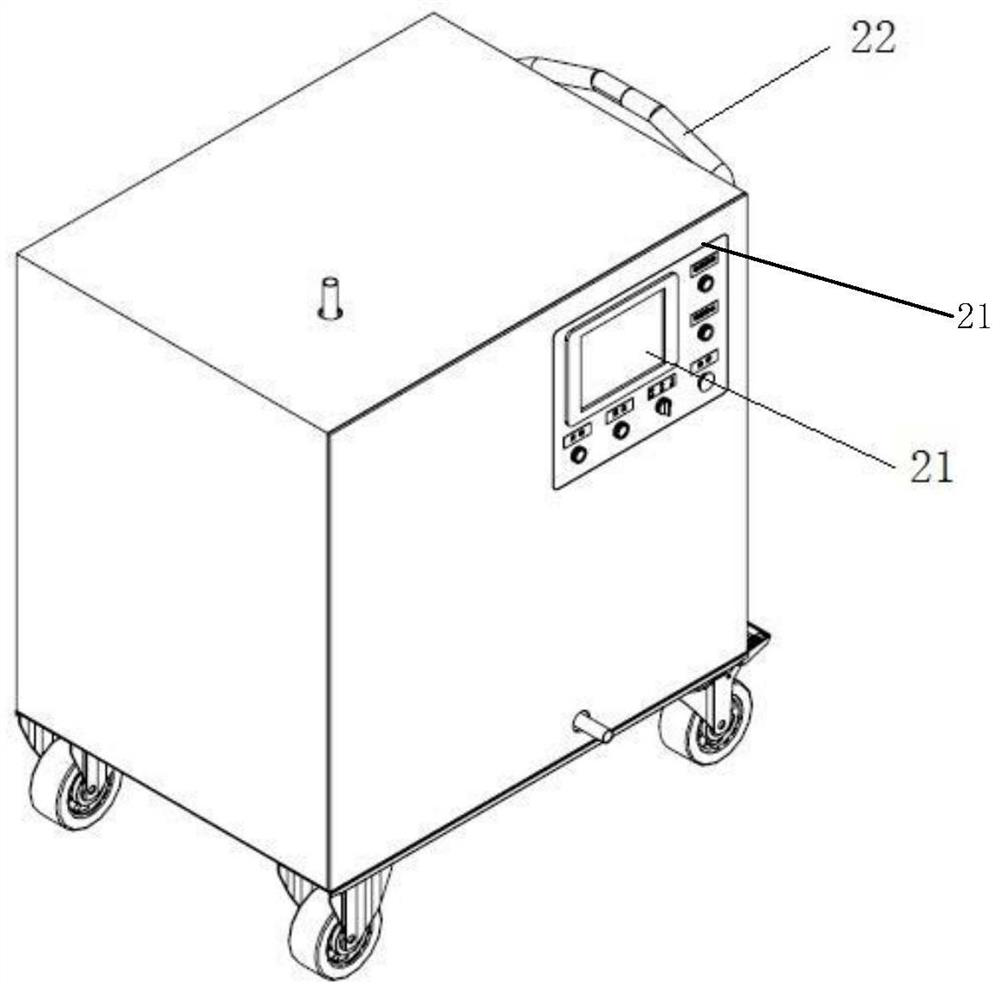

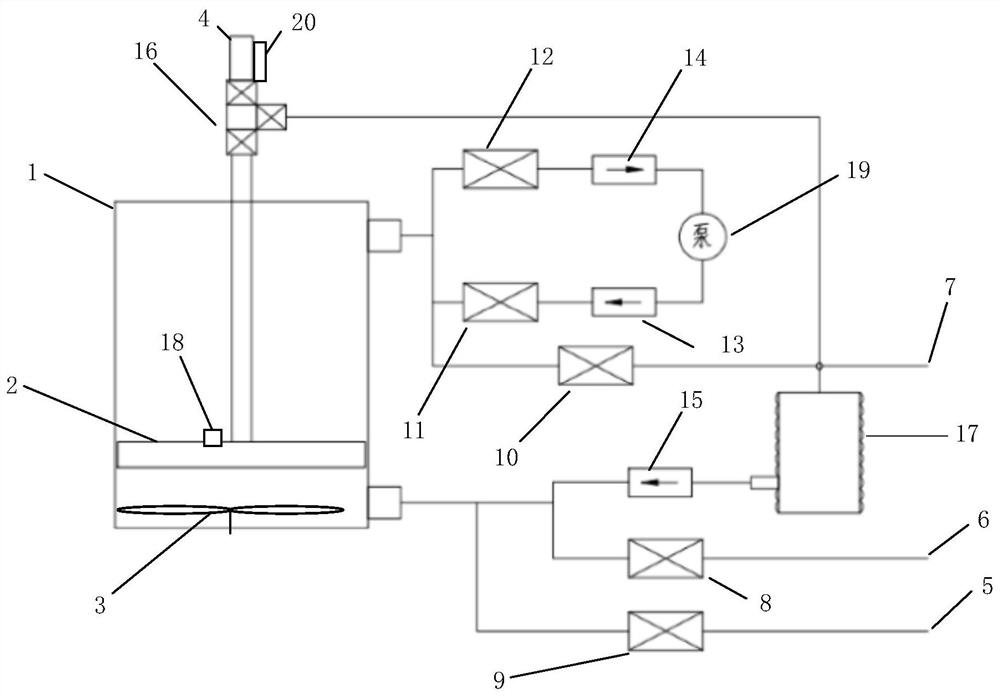

[0034] Such as figure 1 with figure 2 As shown, the standard oil sample automatic quantitative mixer for inspection of the dissolved gas in oil onl...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap