Operation method for man-machine collaborative inspection of power distribution network

A technology of man-machine and unmanned aerial vehicles, which is applied in the direction of closed-circuit television system, inspection time patrol, non-electric variable control, etc., can solve the problems of manual inspection time-consuming and low efficiency, and achieve convenient power distribution network inspection Operation, strong practicability, manual inspection to adapt to the effect of a wide area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

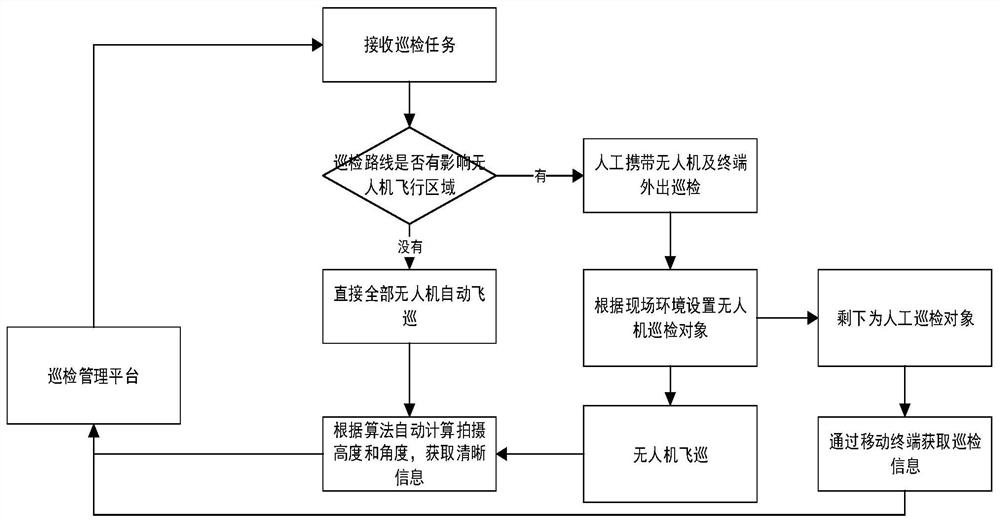

Method used

Image

Examples

Embodiment 1

[0047] The targets of the inspection include Yuchang towns and rural areas, and the length of the entire power supply network is 4km. There is no electrified railway nearby, and there is no high-grade power supply line crossing. During the inspection, the personnel set the inspection target located in the town as manual, and the rest of the objects are assigned to the drone. Calculate the hovering angle according to the tower height and tower properties (tension resistance, branch line, branch) of the target object. For example, when the information is a 10-meter tension rod and there is no branch inspection, calculate the angle of the pole's entry and exit line (based on latitude and longitude), Then, according to the focal length of the camera on both sides of the incoming and outgoing lines, take clear photos of the insulating string porcelain bottles at both ends as close as possible.

Embodiment 2

[0049] The inspection target is located in a mountainous country, and if it is crossed by other power lines, it can be all assigned to the UAV, and the UAV first calculates the route with the least leap over the area based on the cross-crossing information of the inspection object. When approaching the crossing area, the flight altitude is automatically calculated, and the flight speed is reduced at the same time, reminding manual video surveillance, slowly flying over the crossing area, and then patrolling normally to ensure the safety of inspections.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com