Manufacturing process of personalized customized pressure comfortable shapewear

A technology of making crafts and body shaping clothes, which is applied to sewing tools, underwear, corsets, etc. It can solve the problems of ignoring the restraint pressure and poor body shaping effect, and achieve good body shaping effect, strong fit, and ensure accuracy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

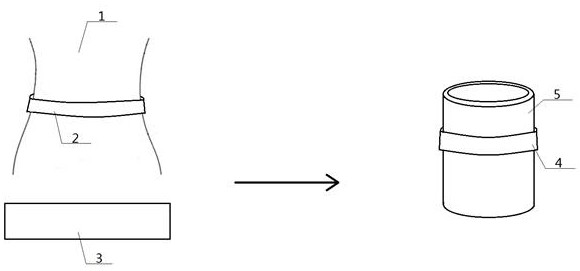

[0053] see figure 1 — Figure 4 , a manufacturing process of personalized custom pressure comfort type shapewear, comprising the following steps:

[0054] Step 1: Use the measuring tape 2 to wrap a single circle around the waist of the customer 1 (the original circumference is 80 cm), and then shorten the measuring belt 2 to shrink the waist of the customer 1 until the customer 1 feels uncomfortable, then measure The length of belt 2 at this time is the body-shaping waist circumference (65 cm) of the customizer 1. At the same time, the pressure (3.5KPA) exerted by the measurement belt 2 on the waist of the customizer 1 at this time is measured as the body-shaping pressure;

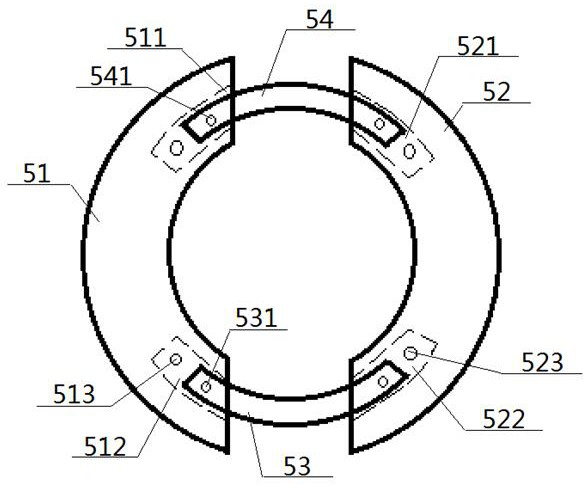

[0055] Step 2: First select the target fabric 3 that will be used to make the shapewear later, then select the strip-shaped target fabric 3 as the measuring fabric 4, and then select the measuring cylinder 5. The side circumference length of the measuring cylinder 5 is equal to the waist circumference of ...

Embodiment 2

[0058] Basic content is the same as embodiment 1, the difference is:

[0059] Customizer 1's waist has an original circumference of 81 cm, a body shaper waist of 72 cm, and a waist custom fabric length of 60 cm.

Embodiment 3

[0061] Basic content is the same as embodiment 1, the difference is:

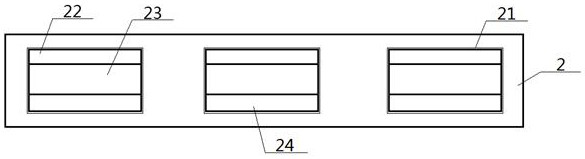

[0062] The inside of the measuring tape 2 is provided with a plurality of pressure measuring chambers 21, all of which are sequentially arranged along the axial direction of the measuring tape 2, and the inside of each pressure measuring chamber 21 is filled with a front adhesive layer 22, The middle conductive layer 23 and the rear adhesive layer 24, one side of the front adhesive layer 22 is bonded to the cavity wall of the pressure measurement chamber 21, and the other side of the front adhesive layer 22 is bonded to the rear through the middle conductive layer 23 One side of the layer 24 is bonded, and the other side of the rear bonding layer 24 is bonded to the cavity wall; the middle conductive layer 23 is formed by smearing conductive powder. The conductive powder is any one or any mixture of metal powder, graphite powder and carbon black powder.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com