Latex bubble filtering device and latex supply system

A filter device and latex technology, which is applied in the field of cigarette production, can solve the problems of wasting latex, not being able to find the existence of air bubbles, and taking a long time, so as to achieve the effect of convenient exhaust

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The embodiments described below by referring to the figures are exemplary only for explaining the present invention and should not be construed as limiting the present invention.

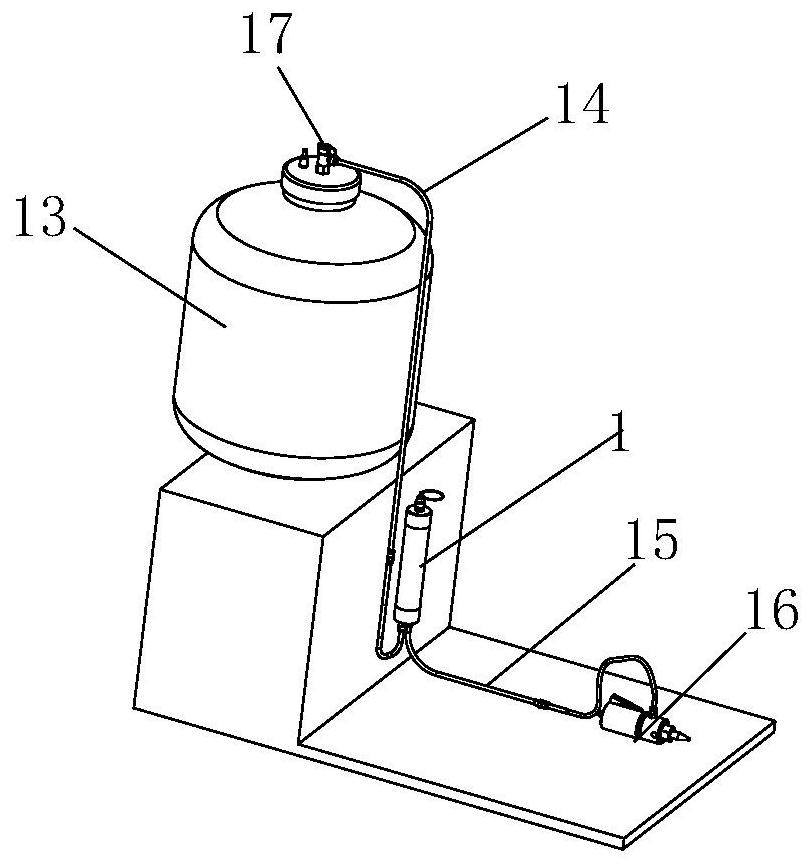

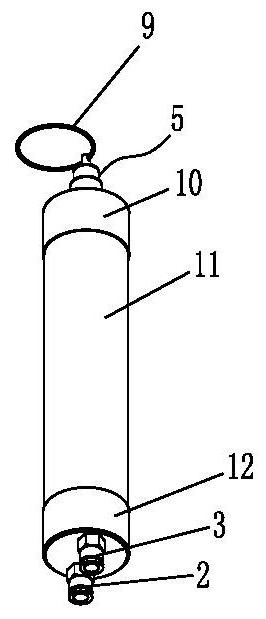

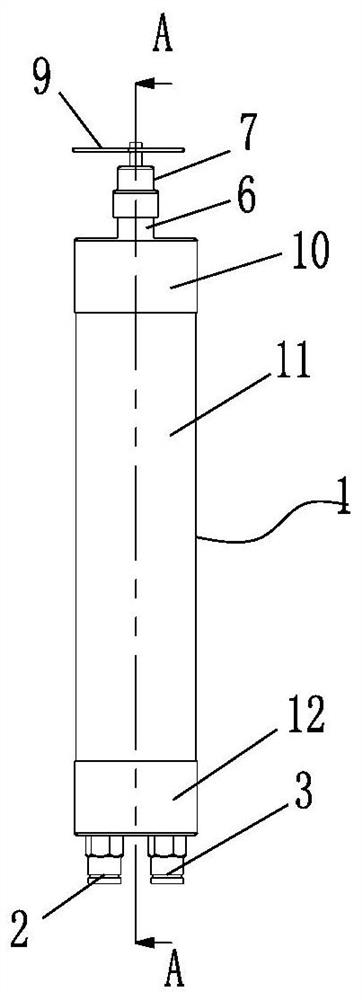

[0038] Please refer to Figure 1 to Figure 4 , the present invention proposes a latex bubble filter device, which includes a filter cartridge 1, and the filter cartridge 1 can be a cylinder, a square cylinder, or a cylinder of other shapes. As a result, the filter cartridge 1 should have a certain depth in the longitudinal direction, and the inner wall should be arranged smoothly.

[0039] Specifically, one end of the filter cartridge 1 is connected with a rubber inlet pipe 2 and a rubber outlet pipe 3; Relatively large static space, since the pressure in the filter cartridge 1 is not much different, and the glue outlet is located below the filter cartridge 1, when the glue with bubbles enters the filter cartridge 1, the bubbles will be under the action of buoyancy The lower rise finally ac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com