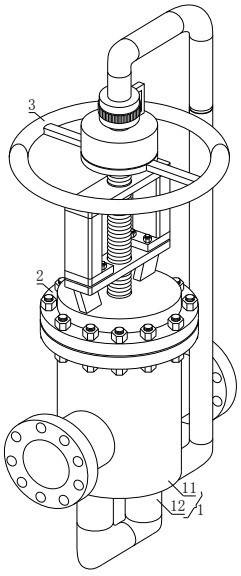

Automatic valve with pressure relief protection structure and implementation method of automatic valve

A protective structure and automatic valve technology, which is applied in the direction of sliding valve, valve shell structure, valve details, etc., can solve the problems of manpower consumption, waste of resources, troublesome operation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach , 1 Embodiment approach

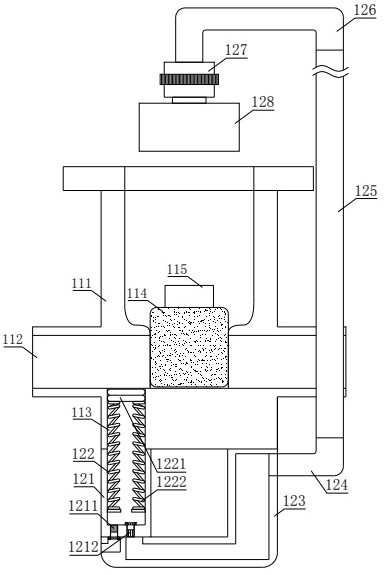

[0042] In order to further and better explain the above-mentioned embodiments, the present invention also provides an embodiment, a method for implementing an automatic valve with a pressure relief protection structure, comprising the following steps:

[0043] Step 1: When the water pressure in the pressure collecting chassis 1 increases, the pressure will push down the rubber pad 1221, and the air in the communication hole 113 will enter the L-shaped connecting cylinder 123 through the second one-way valve 1212, In the first hard connection pipe 124, the telescopic connection long pipe 125 and the second hard connection pipe 126;

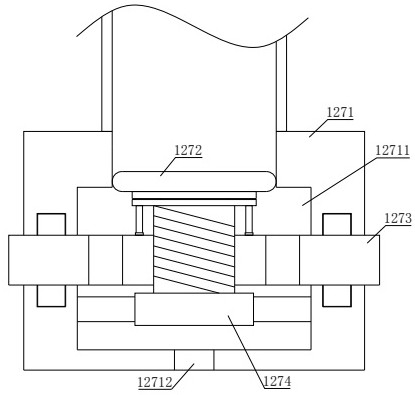

[0044] Step 2: By turning the switch wheel 1273, driven by the second threaded column 12737, the T-shaped installation round block 12735 drives the air outlet rubber pad 1272 to move downward, the L-shaped connecting cylinder 123, the first hard connecting pipe 124, The air in the telescopic connection long pipe 125 and the second hard connection p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com