Cosmetic processing and stirring equipment based on bubble-overflowing prevention technology

A technology for mixing equipment and cosmetics, applied in mixer accessories, mixers with rotating mixing devices, chemical instruments and methods, etc., can solve problems such as punching equipment and material waste, achieve accuracy, improve mixing quality, Ensure the effect of stirring and mixing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

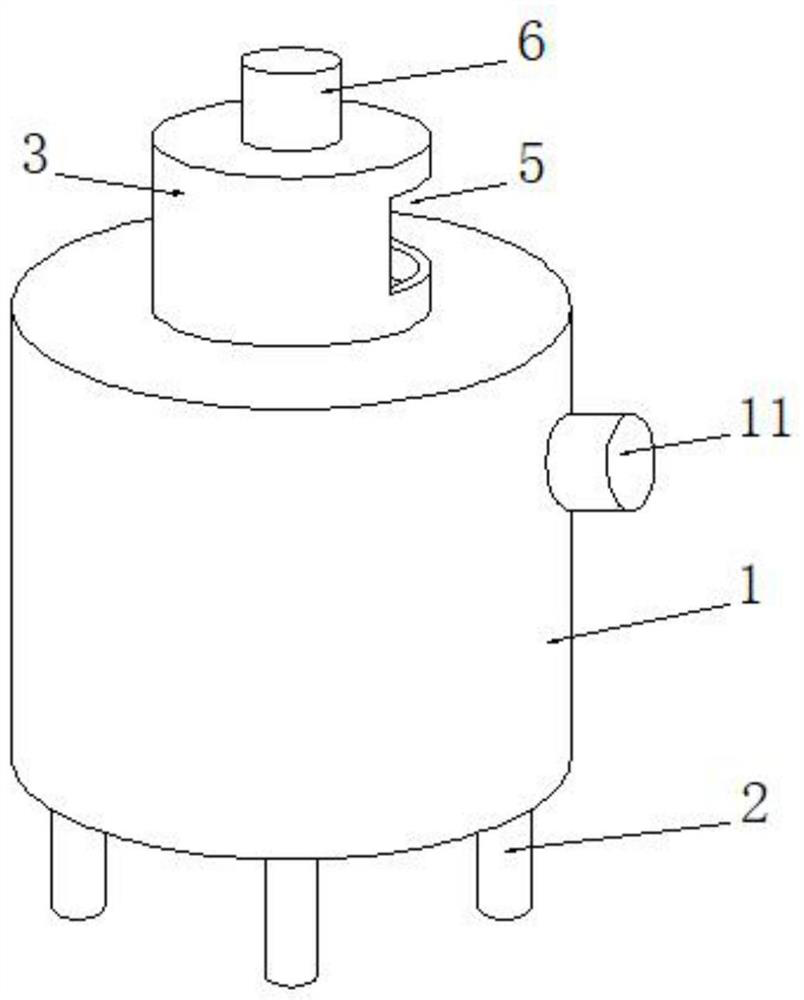

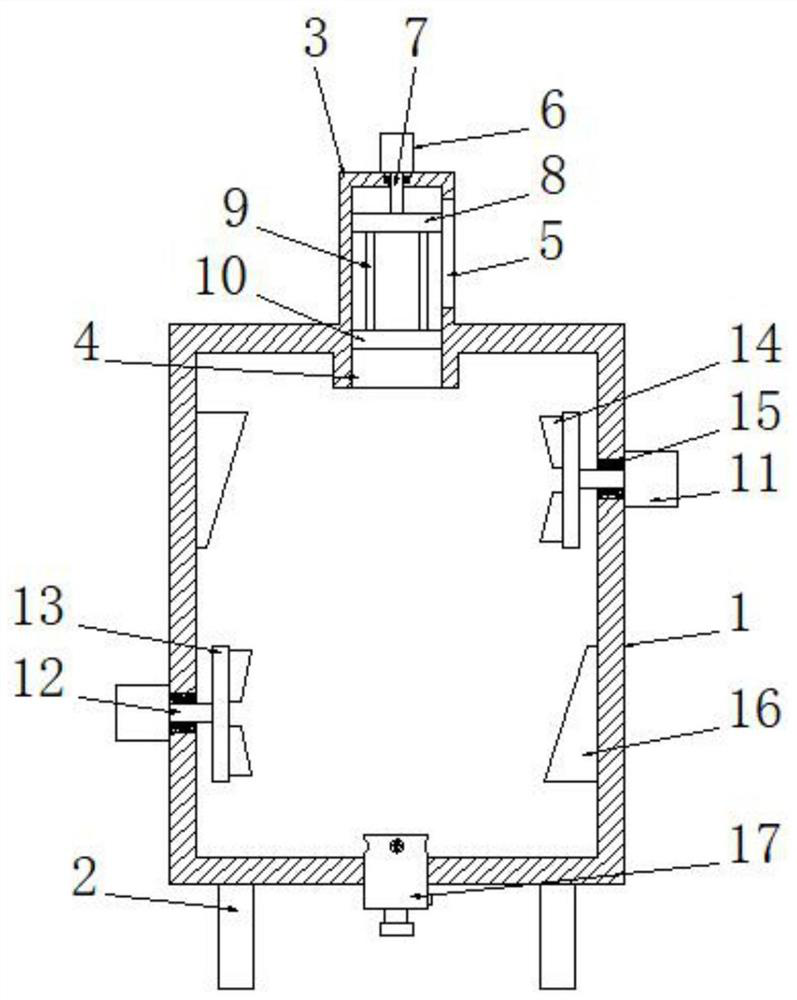

[0029] See Figure 1-2 , a cosmetics processing and stirring equipment based on foaming and overflow prevention technology, comprising a kettle body 1, the bottom of the kettle body 1 is evenly provided with a number of legs 2, and the top of the kettle body 1 is connected to the feeding cylinder 3 through, so The bottom end of the feeding tube 3 is connected to the sealing sleeve 4, and the feeding tube 3 is connected to the kettle body 1 through the sealing sleeve 4. The axis of the feeding tube 3 is overlapped with the axis of the sealing sleeve 4 and the axis of the kettle body 1. One side end of tube 3 connects feeding hole 5 through, and the top of charging tube 3 is fixedly connected with electric telescopic device 6, and the bottom end of telescopic rod 7 on described electric telescopic device 6 is connected with charging tube 3 top wall and is fixedly connected with The upper sealing plate 8 matched with the feeding cylinder 3 is slidingly connected between the teles...

Embodiment 2

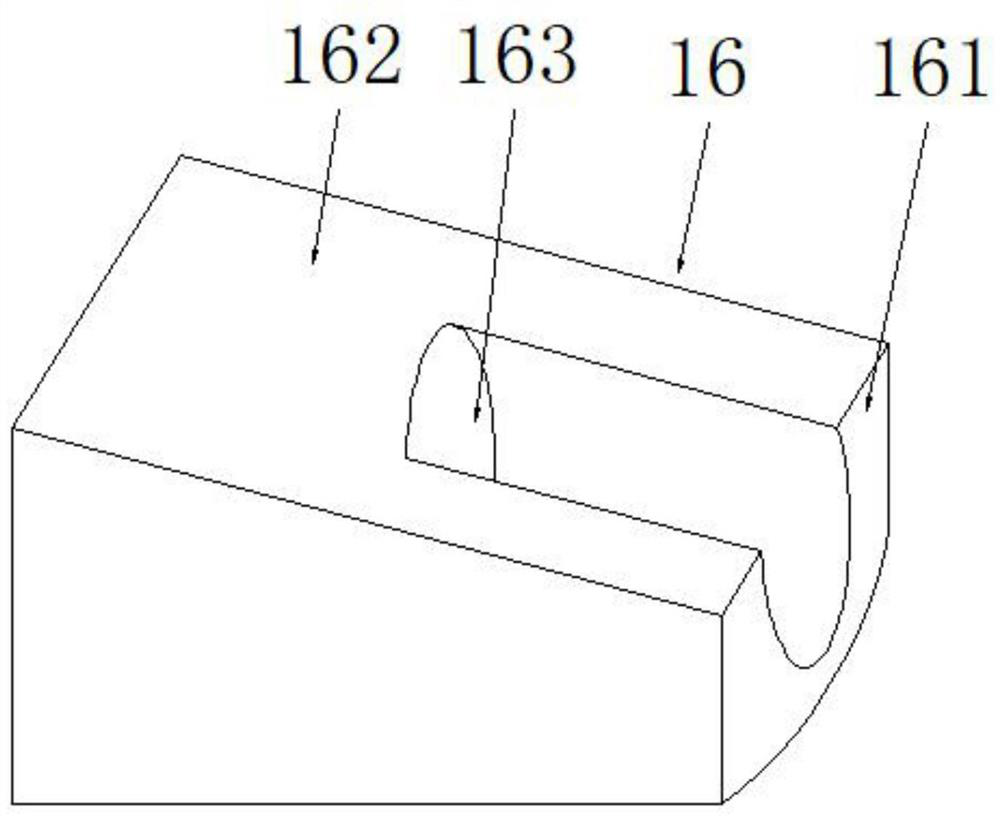

[0033] See Figure 3-4 , the difference from Embodiment 1 is: the deflector assembly 16 includes a plate body 161, the plate body 161 is fixedly connected to the inner cavity wall of the kettle body 1, and the plate body 161 is horizontally connected to the stirring assembly Correspondingly, the side end surface of the plate body 161 is provided with a drainage surface 162, and the drainage surface 162 is arranged obliquely, and the auxiliary pushing hole 163 matched with the drainage surface 162 is provided in the described plate body 161, and the auxiliary pushing hole 163 is provided with An auxiliary push fan 164 is provided, and the auxiliary push fan 164 is fixedly connected to the inner cavity wall of the auxiliary push hole 163 through a fixed rod 165, and the raw material in the kettle body 1 is stirred by the stirring assembly, so that the raw material rushes to the drainage surface 62 and the auxiliary push hole 163. Push the hole 163, and at the same time further p...

Embodiment 3

[0036] See Figure 5-6 , the difference from Example 1 is: the discharge cylinder 17 includes a cylinder 171, the cylinder 171 is a cylindrical structure with an open bottom, and the cylinder 171 is embedded on the bottom wall of the kettle body 1 , the outer circular surface of the cylinder 171 is evenly provided with a number of through holes 172, the through holes 172 are provided with a control valve 173, one side of the cylinder 171 is embedded with a control switch 170, the control switch 170 It is electrically connected with the control valve 173, the bottom end of the cylinder 171 is open and internally threaded to the sealing cover 174, the top of the sealing cover 174 is provided with a diversion hole 175, and the bottom end of the diversion hole 175 The discharge pipe 176 is connected through, the bottom end of the discharge pipe 176 is covered with a sealing plug 177, a number of support rods 178 are evenly arranged in the guide hole 175, and the top ends of all th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com