Test tube shaking device for food detection

A technology for food testing and test tubes, applied in transportation and packaging, dissolving, mixers, etc., can solve the problems of low shaking efficiency, limited liquid shaking range, and low degree of liquid mixing, and achieve high shaking efficiency and smooth shaking large effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

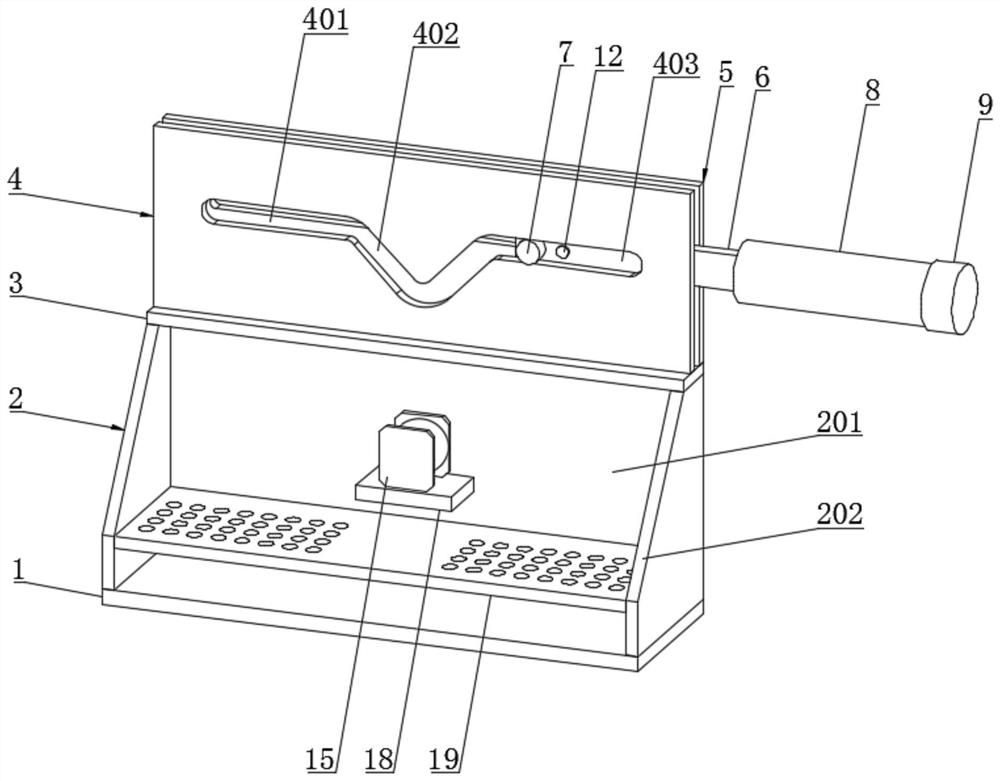

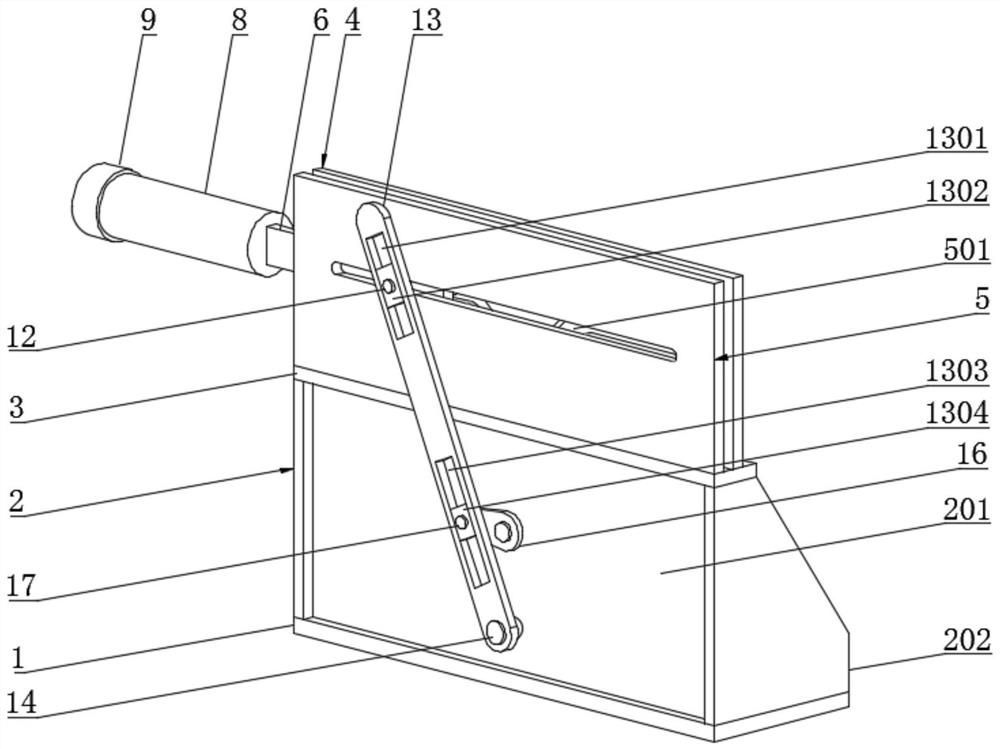

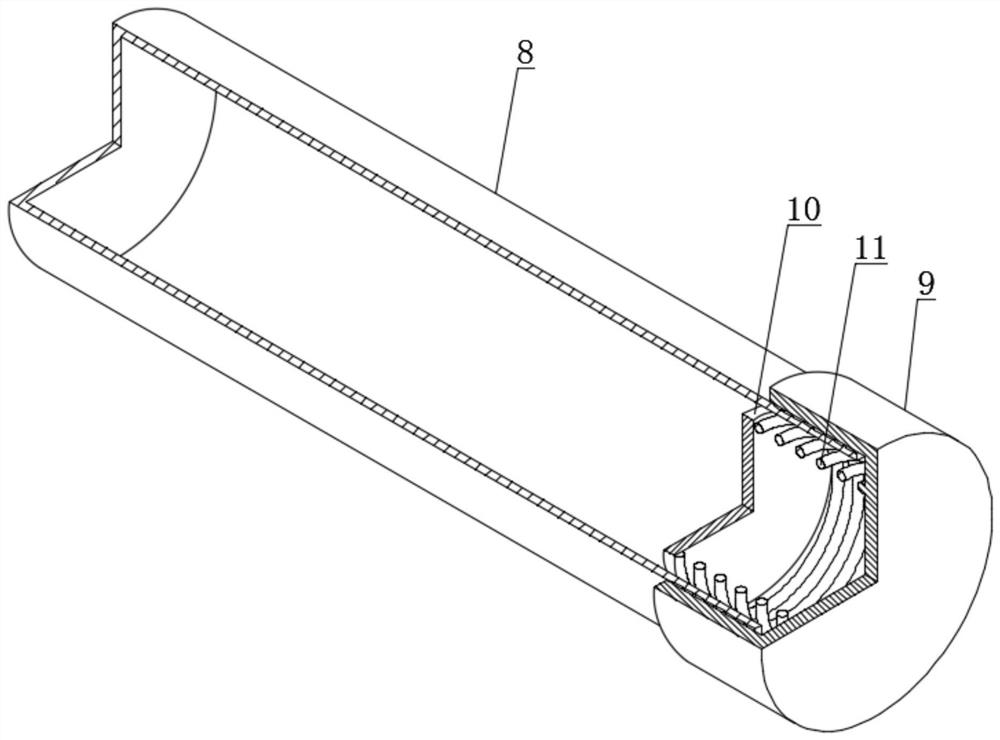

[0020] Example: see figure 1 , the invention provides a test tube shaking device for food testing, comprising a base 1, the top of the base 1 is equipped with a support frame 2 through bolts, the support frame 2 consists of a back plate 201 and side plates positioned on the left and right sides of the back plate 201 202 are bolted to each other. The top of the support frame 2 is equipped with a support plate 3 through bolts, and the top of the support plate 3 is equipped with a track plate 4 and a limit plate 5 distributed in parallel front and rear through bolts. The track plate 4 is provided with a track groove, and the track groove is composed of a first straight groove 401, a V-shaped groove 402 and a second straight groove 403 which are connected successively from left to right. The first straight groove 401 and the second straight groove 403 are about The V-shaped groove 402 is left-right symmetrical, and a track block 7 slidingly fitted with the track plate 4 is arrang...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com