Putty powder mixing device for building

A technology of mixing device and putty powder, which is applied to mixers, mixers with rotating stirring devices, transportation and packaging, etc., can solve the problems of inconvenient hand-held electric drills for operators and throwing them on operators, so as to improve convenience, Improved work efficiency and improved safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

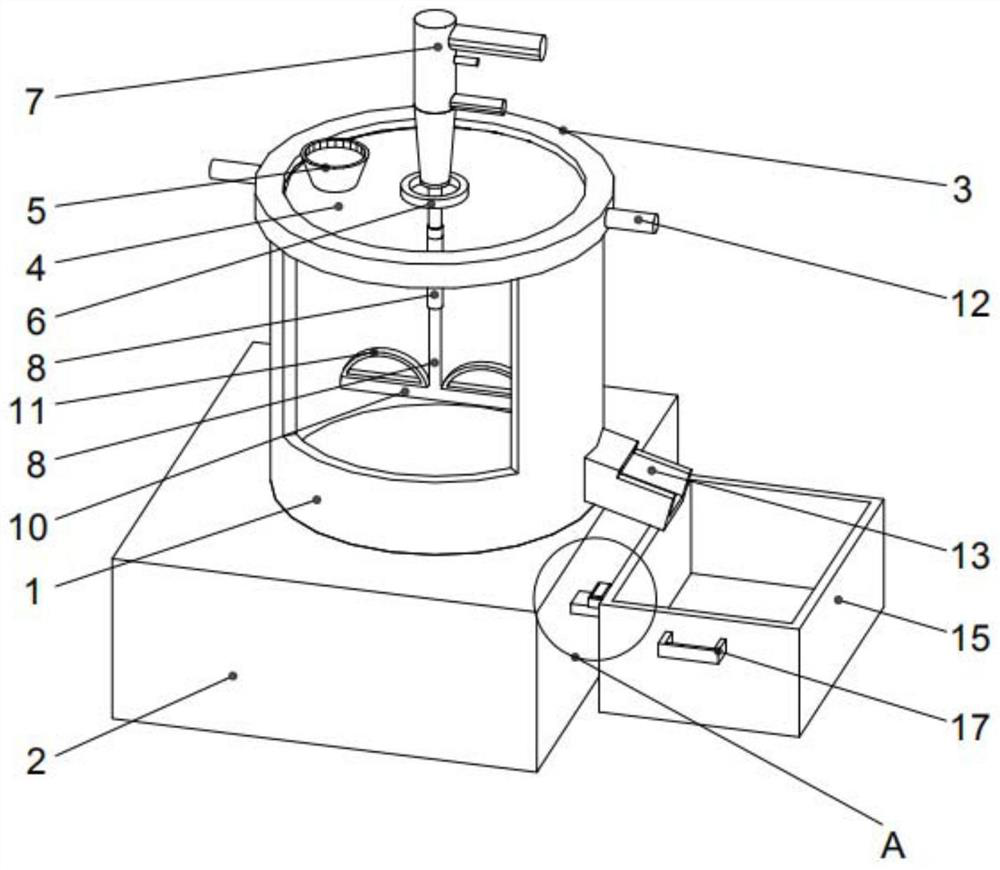

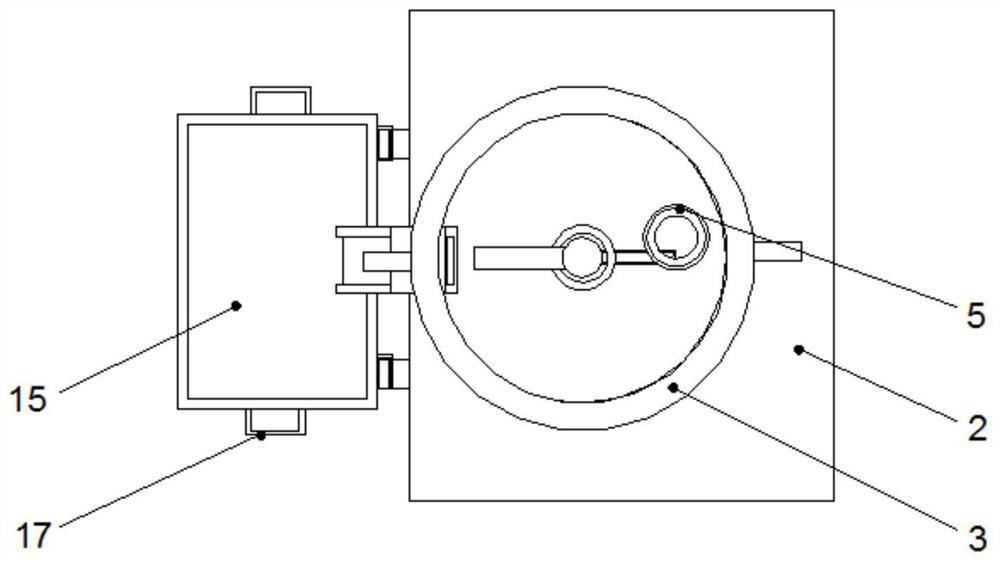

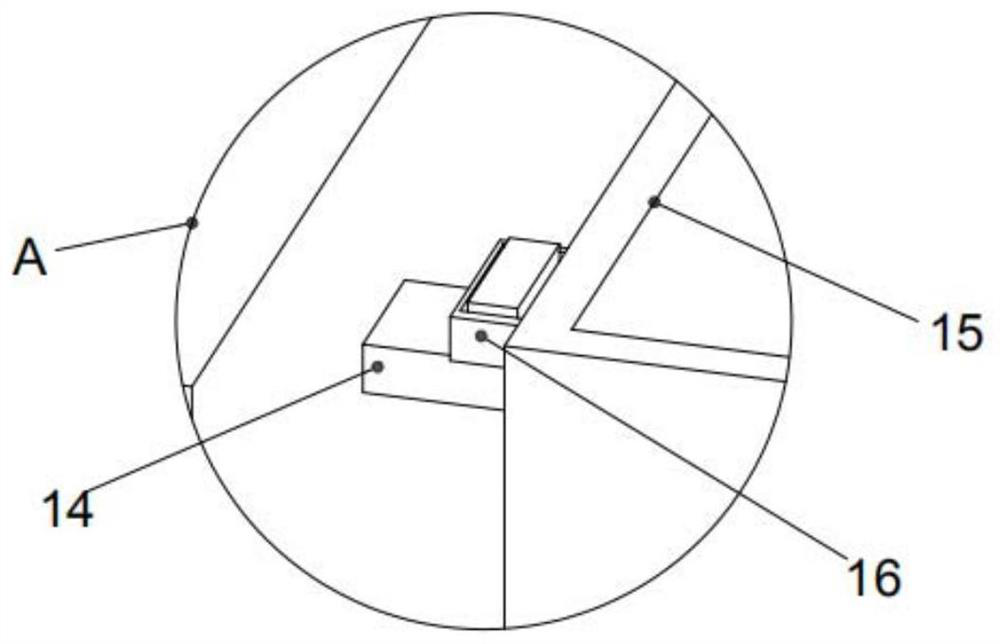

[0021] Example: such as figure 1 , figure 2 and image 3 As shown, a kind of construction putty powder mixing device of the present invention comprises a mixing tank 1 and a base 2, the bottom of the mixing tank 1 is provided with a base 2, the top of the mixing tank 1 is provided with a cover 3, and the cover 3 and the mixing tank 1 are threaded Fixed, the surface of the cover 3 is provided with tempered glass 4, the tempered glass 4 is embedded on the surface of the cover 3, the top of the cover 3 is provided with a feed port 5, the feed port 5 and the cover 3 are fixed by buckles, the tempered glass 4 The middle part is provided with a through hole 6, and the inside of the through hole 6 is provided with an electric drill 7, and the electric drill 7 and the through hole 6 are fixed by interspersing. The rod 9 and the sleeve rod 8 are fixed by threads, and one end of the threaded rod 9 is provided with a cross bar 10, and the cross rod 10 and the threaded rod 9 are fixed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com