A pipeline rapid painting equipment

A painting and pipeline technology, which is applied in the field of rapid pipeline painting equipment, can solve the problems of poor effect and low work efficiency, and achieve the effect of reducing waste, improving work efficiency and good painting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

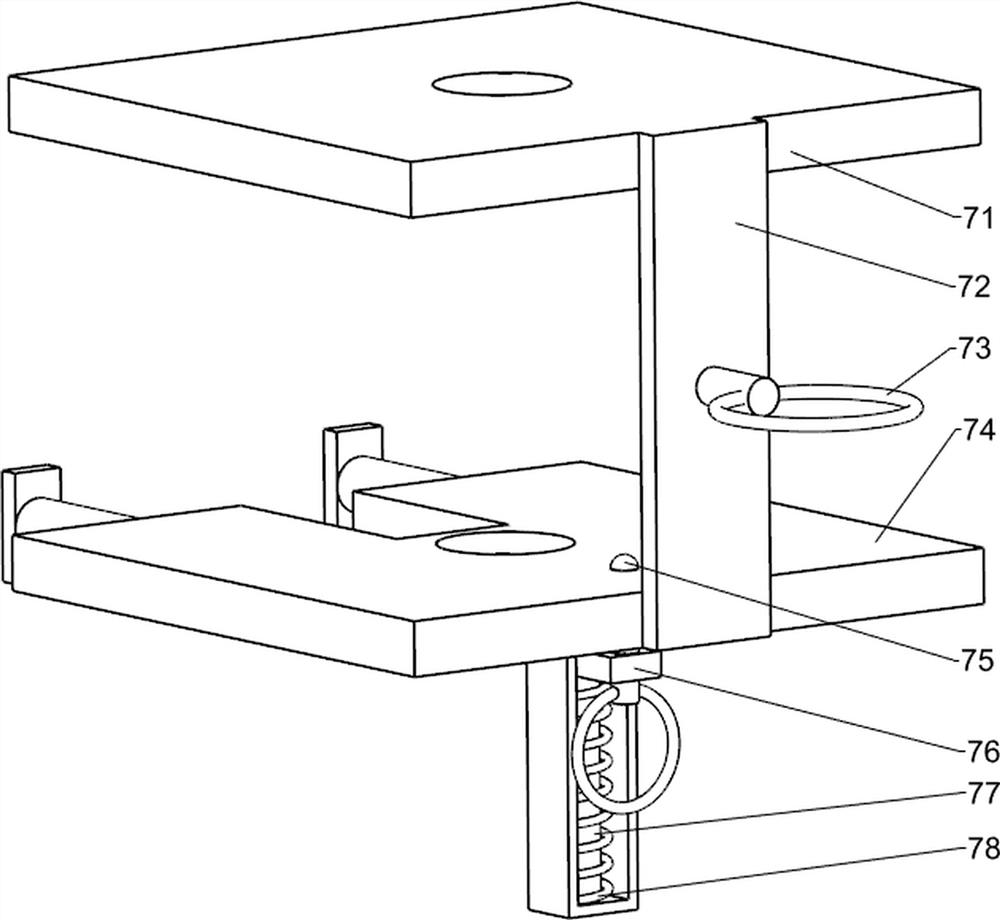

[0083] A pipeline rapid painting equipment, such as figure 1 and figure 2 As shown, it includes a handle 2, a painting mechanism 3 and an unloading mechanism 4, the spraying mechanism passes through the pipeline 1, and the pipeline 1 is located in the working position in the spraying mechanism, and the painting mechanism 3 is provided with a unloading mechanism 4, and the unloading mechanism A handle 2 is provided on a certain part of 4.

[0084] When people need to paint the pipe 1, first fix the pipe 1 manually, then put the whole equipment on the pipe 1, then pour the paint into a certain part of the unloading mechanism 4, push the handle 2 forward, and the handle 2 drives the The whole equipment moves forward, the unloading mechanism 4 transfers the paint to the pipe 1, and the painting mechanism 3 spreads the paint on the pipe 1 evenly. When the pipe 1 is completely painted, pull the handle 2 back, and the handle 2 drives the The device is moved backwards to remove the...

Embodiment 2

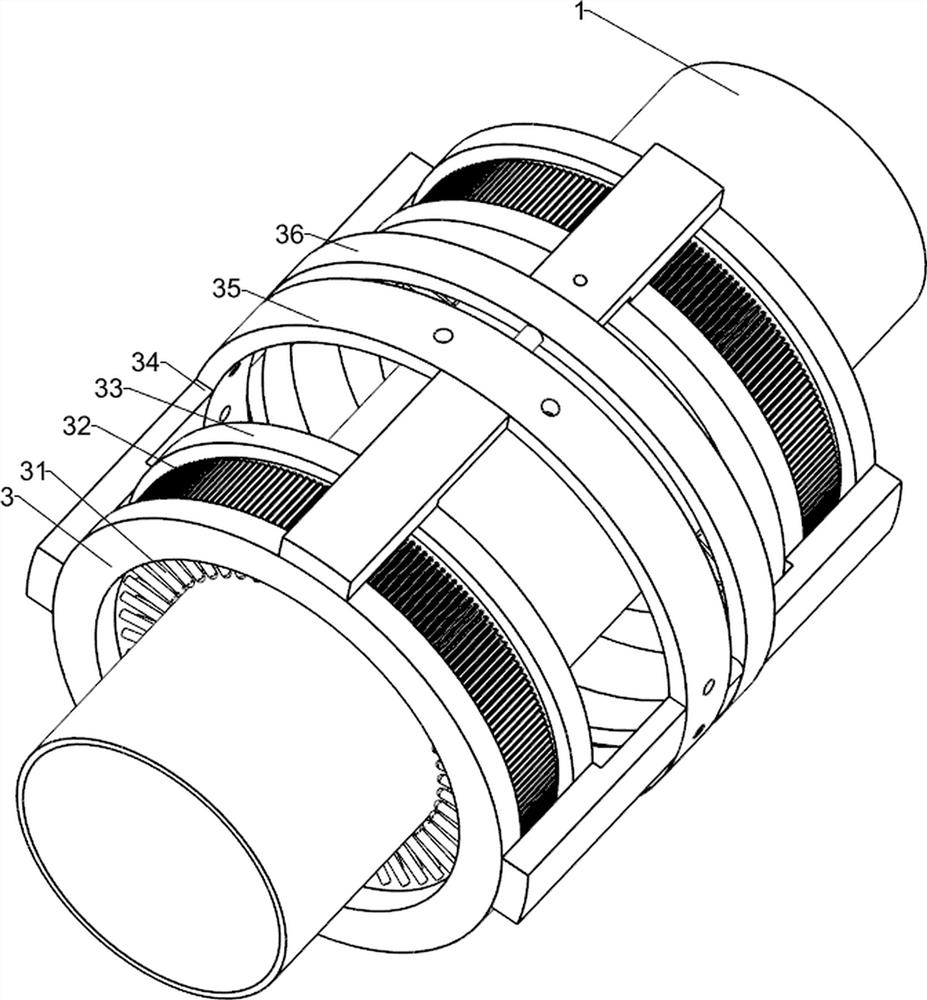

[0086] On the basis of Example 1, as image 3 , Figure 4 , Figure 5 and Image 6 As shown, the painting mechanism 3 includes a brush 31, an external gear 32, a slide rail 33, a fixing plate 34, a first fixing ring 35 and a second fixing ring 36. The rear side of the first fixing ring 35 is provided with a second fixing ring 36. The front side of the first fixing ring 35 and the rear side of the second fixing ring 36 are evenly provided with fixed plates 34, the fixed plates 34 on the same side are symmetrically provided with sliding rails 33 in the front and rear, and the sliding rails 33 on the same side are provided with each other. The rotary type is provided with an external gear 32 , and the inner side of the external gear 32 is evenly provided with brushes 31 .

[0087] When people need to paint the pipe 1, first fix the pipe 1 manually, then put the whole equipment on the pipe 1, make the pipe 1 pass through the first fixing ring 35 and the second fixing ring 36, a...

Embodiment 3

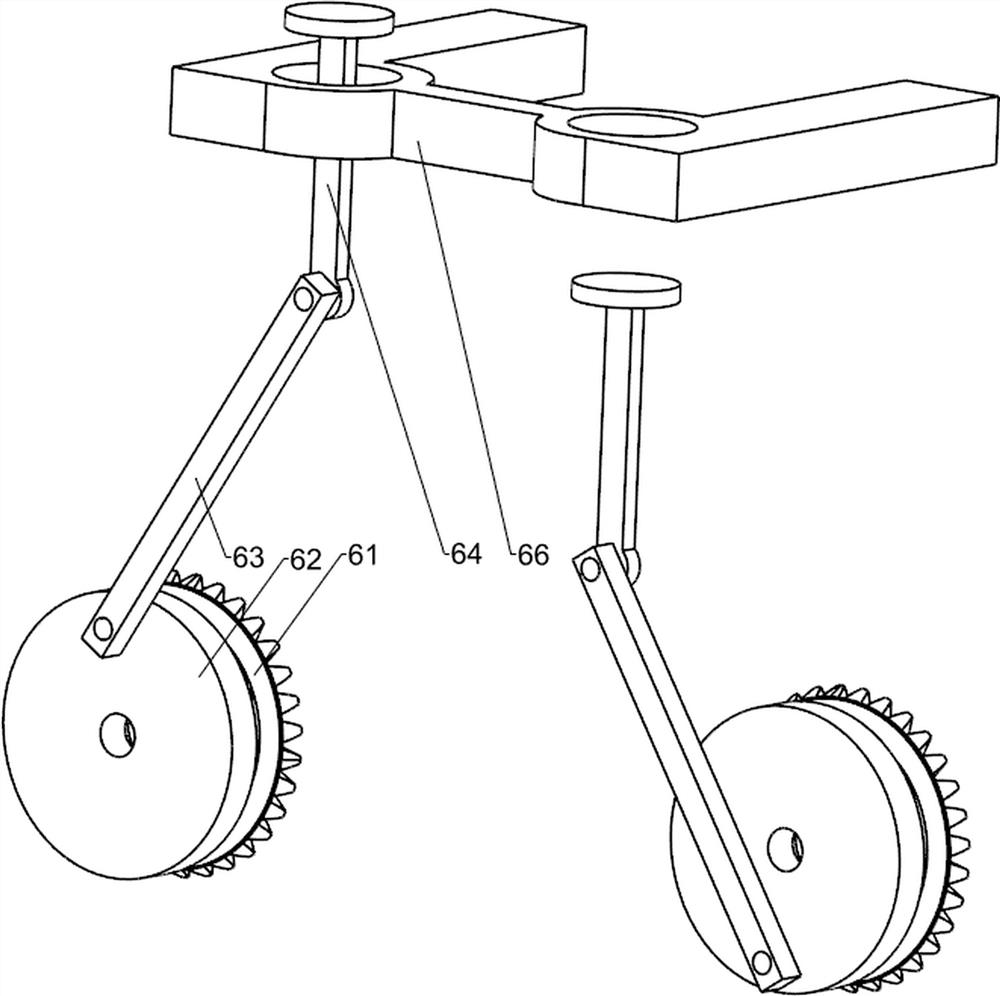

[0093] On the basis of Example 2, as Figure 7 , Figure 8 , Figure 9 , Figure 10 , Figure 11 and Figure 12 As shown, it also includes a discharge device 6, and the discharge device 6 includes a third bevel gear 61, a disc 62, a connecting rod 63, a piston 64, a cylinder 65, a bracket 66, a discharge pipe 67 and a second one-way The valve 68 and the front part of the transmission shaft 55 are all rotatably provided with a disc 62, and the rear side of the disc 62 is provided with a third bevel gear 61, and the third bevel gear 61 is rotatably connected to the front part of the transmission shaft 55 on the same side, The third bevel gears 61 are meshed with the first bevel gears 54 on the same side. The front side of the disc 62 is provided with a connecting rod 63 in a rotating manner. The lower part of the front side of the support plate 41 is provided with a bracket 66. There is a cylinder 65, the top of the cylinder 65 is connected with the lower part of the feedin...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap