Electronic component mounting method and apparatus

An installation method and a technology for installation devices, which are applied in the direction of assembling printed circuits of electrical components, electrical components, electrical components, etc., can solve the problems of worthless suction nozzle 9 moving vertically and reducing productivity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0063] Before describing the working sequence of the present invention, it is reminded that like parts are indicated by the same reference numerals in all corresponding drawings.

[0064] An electronic component installation method and device according to an embodiment of the present invention will be described below with reference to FIGS. 1 to 6 . Note that all structures of the electronic component mounting device and component mounting head are almost similar to those of the reference Figure 7 and 12 The structure of the prior art is described, so those structural parts that are the same as those of the prior art structure will not be further described.

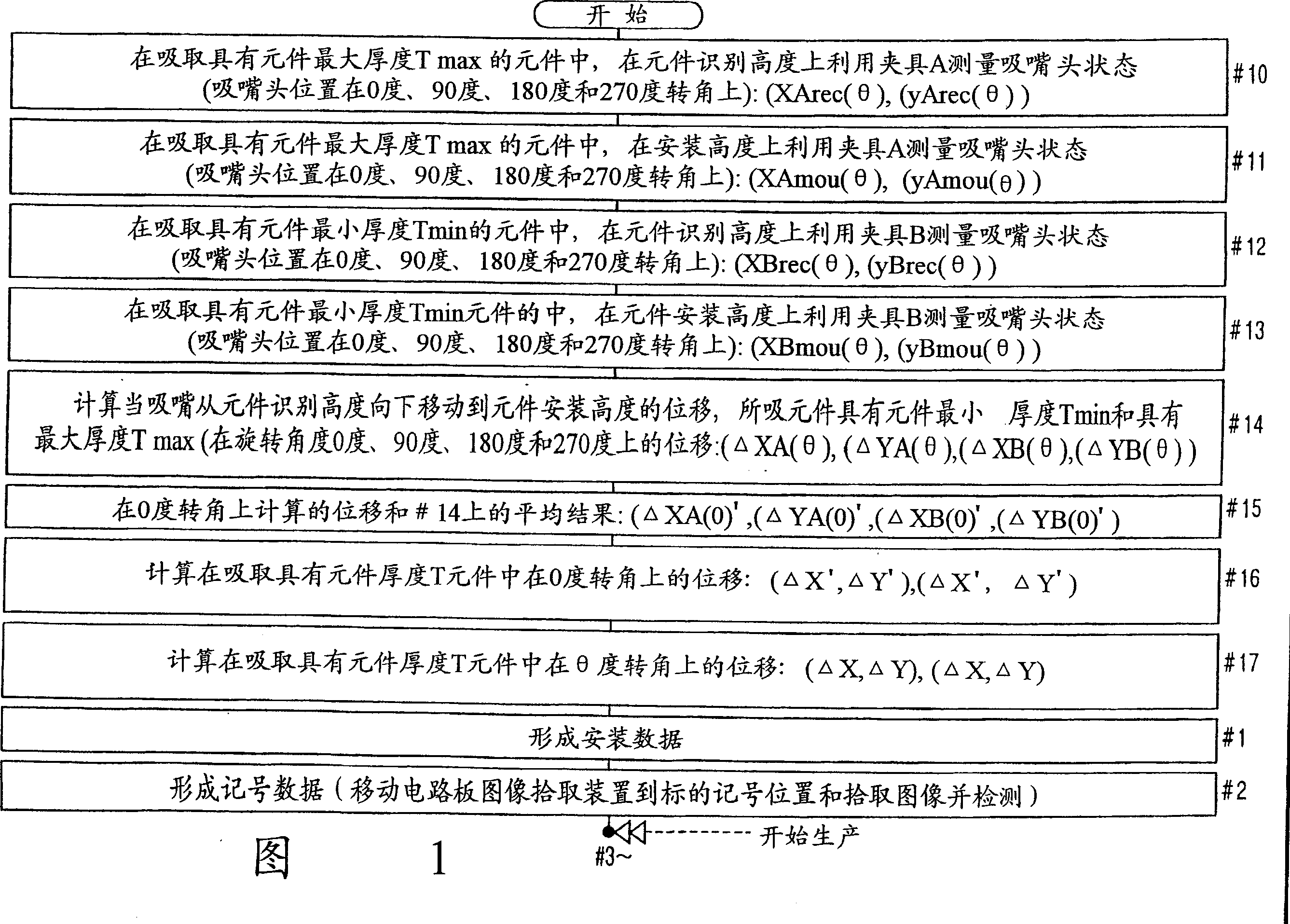

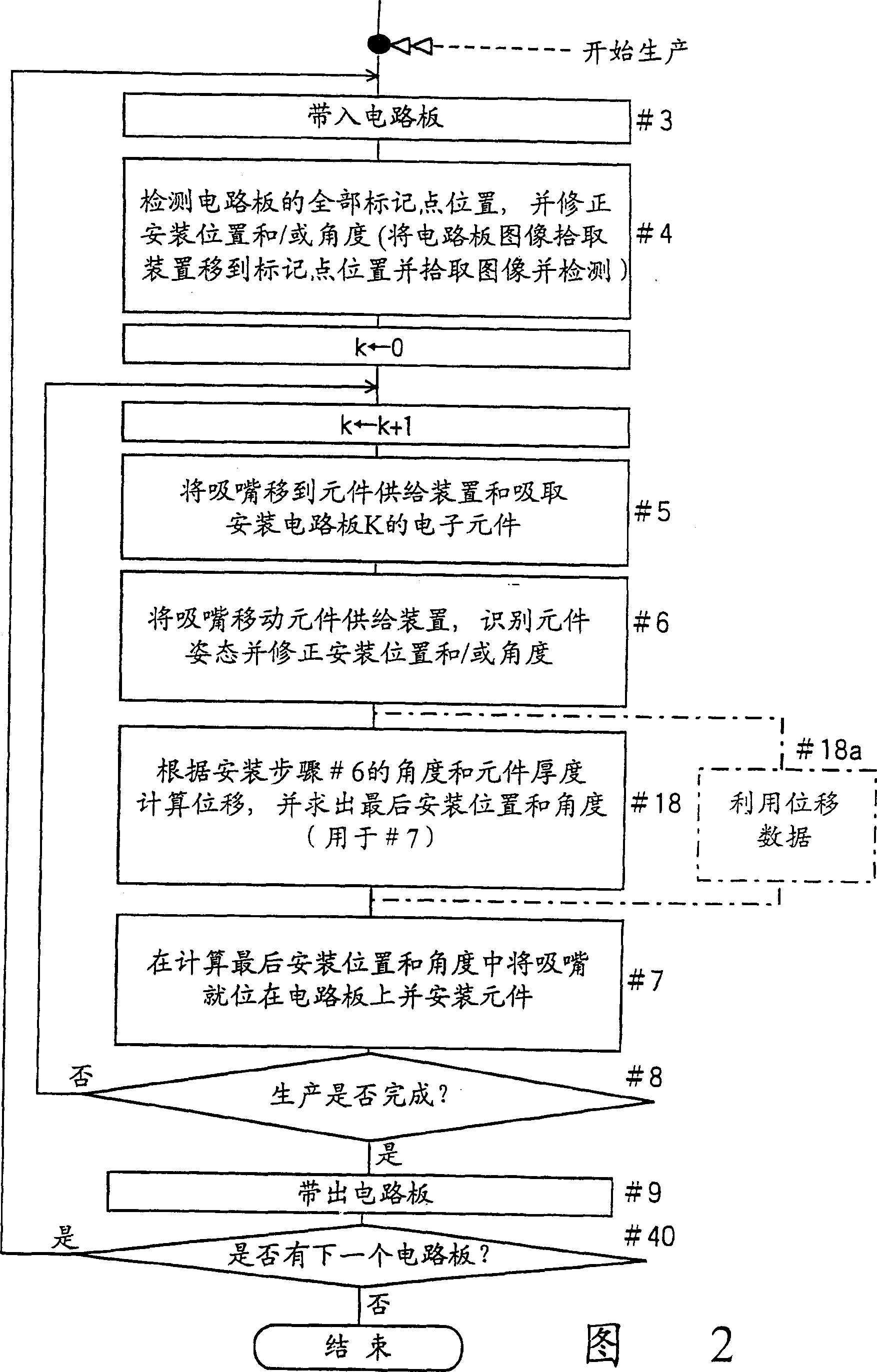

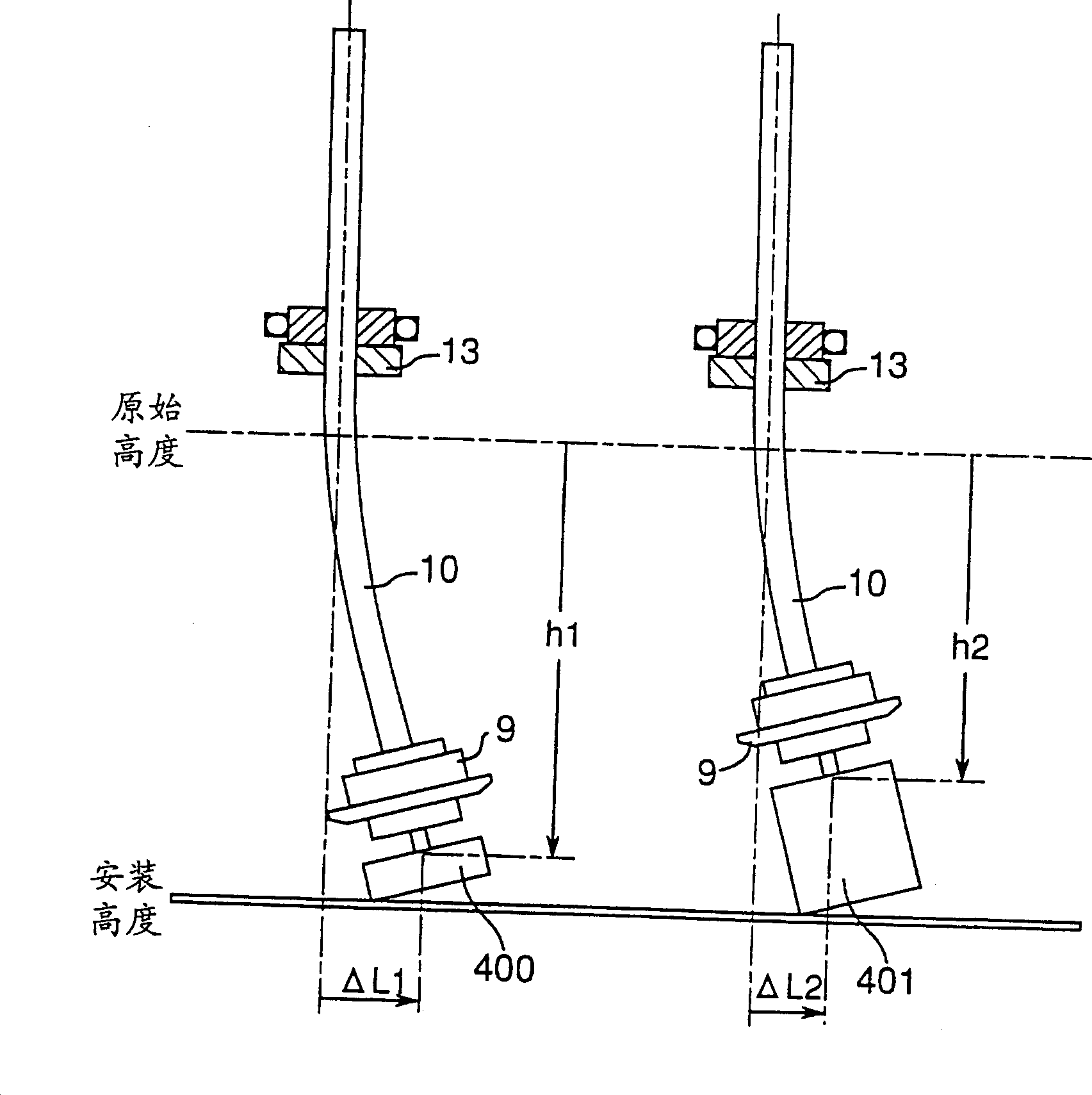

[0065] In this embodiment, as shown in Figure 1, more important than the production of the circuit board is to measure the displacement of the suction nozzle head according to the bending of the axis when the suction nozzle moves vertically and rotationally before production, for example, to obtain the displacement produ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com