Full-automatic shaping vacuum material conveying line

A conveyor line, fully automatic technology, applied in the direction of transportation and packaging, packaging, rollers, etc., can solve the problems of damage to the conveyor line, laborious transportation, heavy gravity of rice packaging bags, etc., to reduce the knock-down force, reduce damage, Effort-saving delivery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

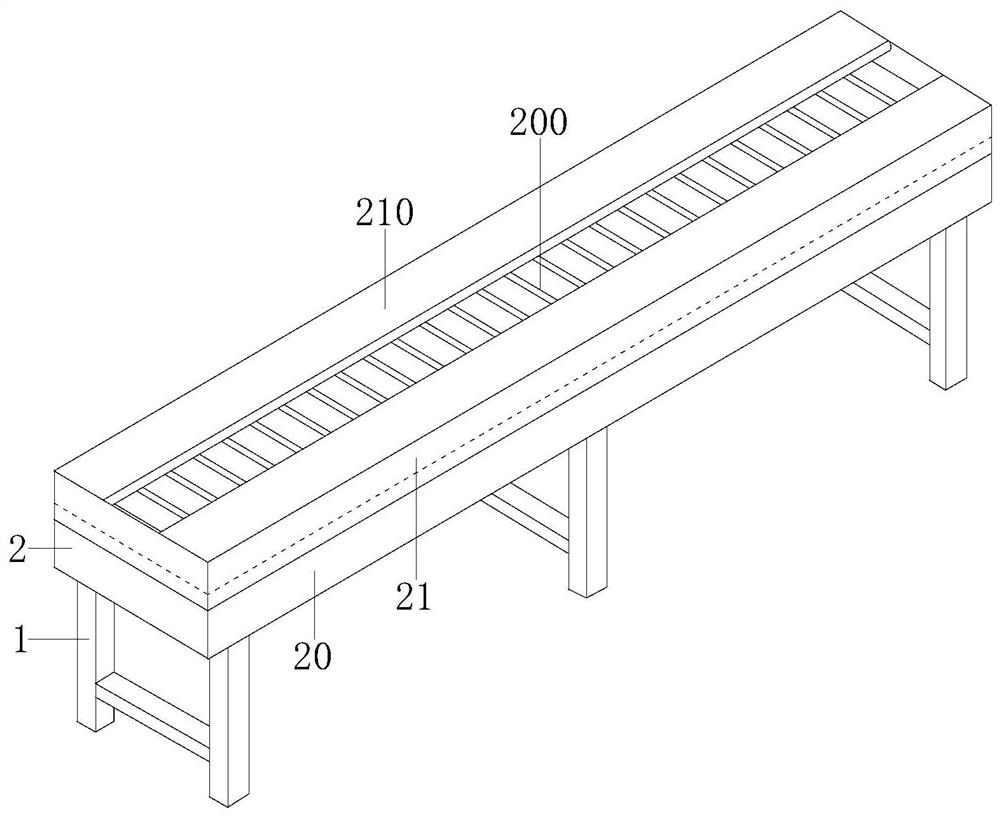

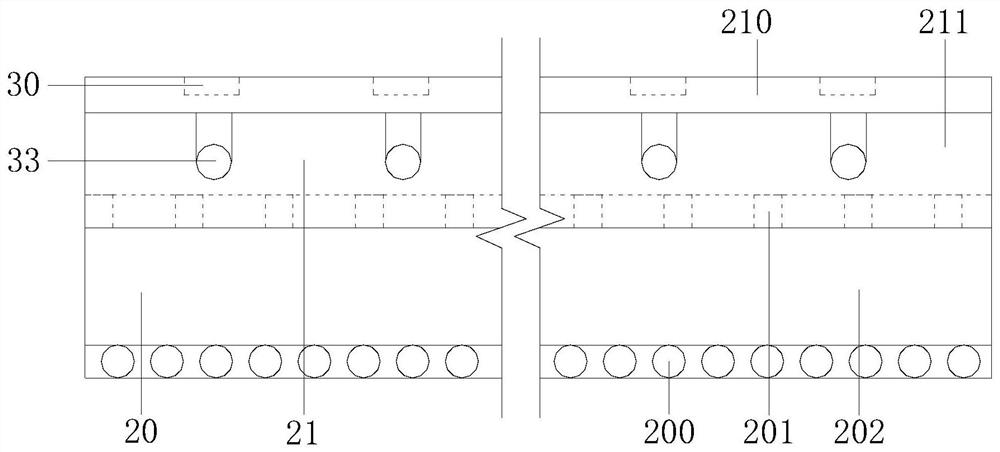

[0024] Example 1 see Figure 1-4 , the present invention provides a technical solution for a fully automatic plastic vacuum material conveying line: its structure includes a supporting foot 1 and a conveying platform 2, the supporting foot 1 is locked with the conveying platform 2, and the conveying platform 2 is conveyed by a bottom frame 20 and a conveying platform 2. The main frame 21 is composed of the bottom frame 20 and the conveying main frame 21. The bottom frame 20 includes a conveying roller line 200, a bottom buffer 201, and a bottom frame body 202. The conveying roller line 200 and the bottom frame The main body 202 is installed and connected. The bottom frame body 202 is equipped with a bottom buffer 201. When the material falls to the conveying roller line 200, the bottom buffer 201 plays a buffering role while falling. The conveying main frame 21 includes a movable Wing plate 210, upper main frame 211, described movable wing plate 210 is installed on upper main ...

Embodiment 2

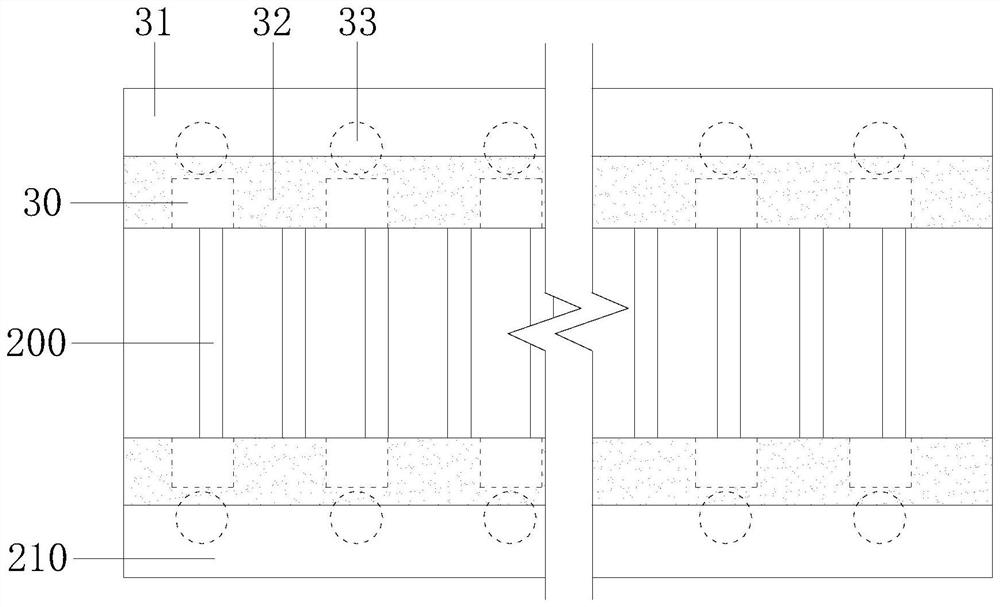

[0026] Example 2 see Figure 5 , the present invention provides a technical solution for a fully automatic shaping vacuum material conveying line: the structure of the feeder 30 includes a tire 300, a wheel frame 301, a wheel mounting frame 302, and a lifter 303, and the tire 300 is installed and connected to the wheel frame 301 , the wheel frame 301 is connected to the wheel frame 302 shaft, the wheel frame 302 is connected to the lifter 303 track, the wheel frame 301, the lifter 303 are connected to the motor, and the wheel frame 302 is welded with elastic welding Sheet 3020, the lifter 303 is installed on the wing plate body 31, the tire 300 is attached to the rubber layer 32, and the rubber layer 32 is a rubber layer to facilitate the lifting movement of the feeder 30.

[0027] When the feeder 30 was in operation, the motor drives the wheel mount 302 and the lifter 303. (The rubber layer 32 is a rubber layer to facilitate the feeder 30 to do lifting activities). Fitting w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com