A wall cutter bracket

A cutting machine and bracket technology, which is applied in the manufacture of tools, work accessories, stone processing equipment, etc., can solve the problems of taking up a lot of space, consuming a lot of physical strength, and unstable center of gravity, so as to achieve high work efficiency, reduce falling force, The effect of improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to make the purpose, technical scheme and advantages of the present invention clearly understood, now in conjunction with the attached Figure 1-10 The present invention will be described in detail.

[0026] For the convenience of expression, the structural orientation of the bracket and the sliding box is determined as the front plate, the rear plate, the upper plate, the lower plate, and the two ends as the end plates.

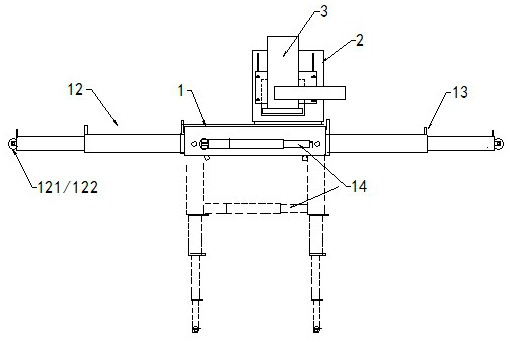

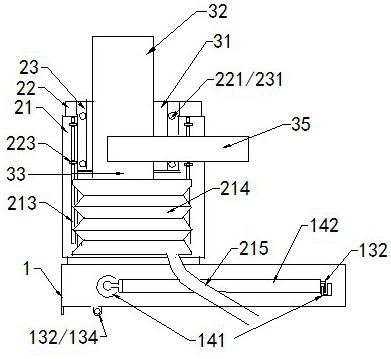

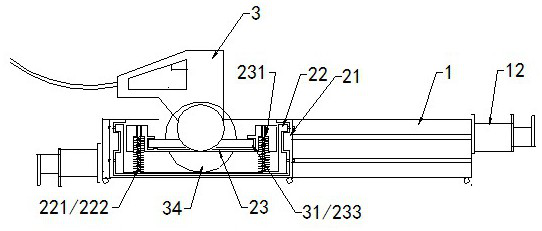

[0027] Such as figure 1 As shown, a bracket for a wall cutting machine includes a bracket 1 and a sliding box 2, the bracket 1 moves and installs the sliding box 2 in the upper plate slideway 10, and the inherent cutting machine 3 is inserted in the sliding box.

[0028] 1. Holder.

[0029] Such as Figure 5 Figure 7 Figure 8 As shown, the bracket 1 is a horizontal rectangular columnar body. The upper plate of the bracket is provided with a slideway 10 parallel to the long side, the slideway is an indented groove or a protruding clip,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com