Curtain production and processing lockstitch sewing machine convenient for tidying

A technology for lockstitch sewing machines and curtains, which is applied in the field of locket sewing machines to achieve the effects of reducing labor force, saving space and improving sewing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

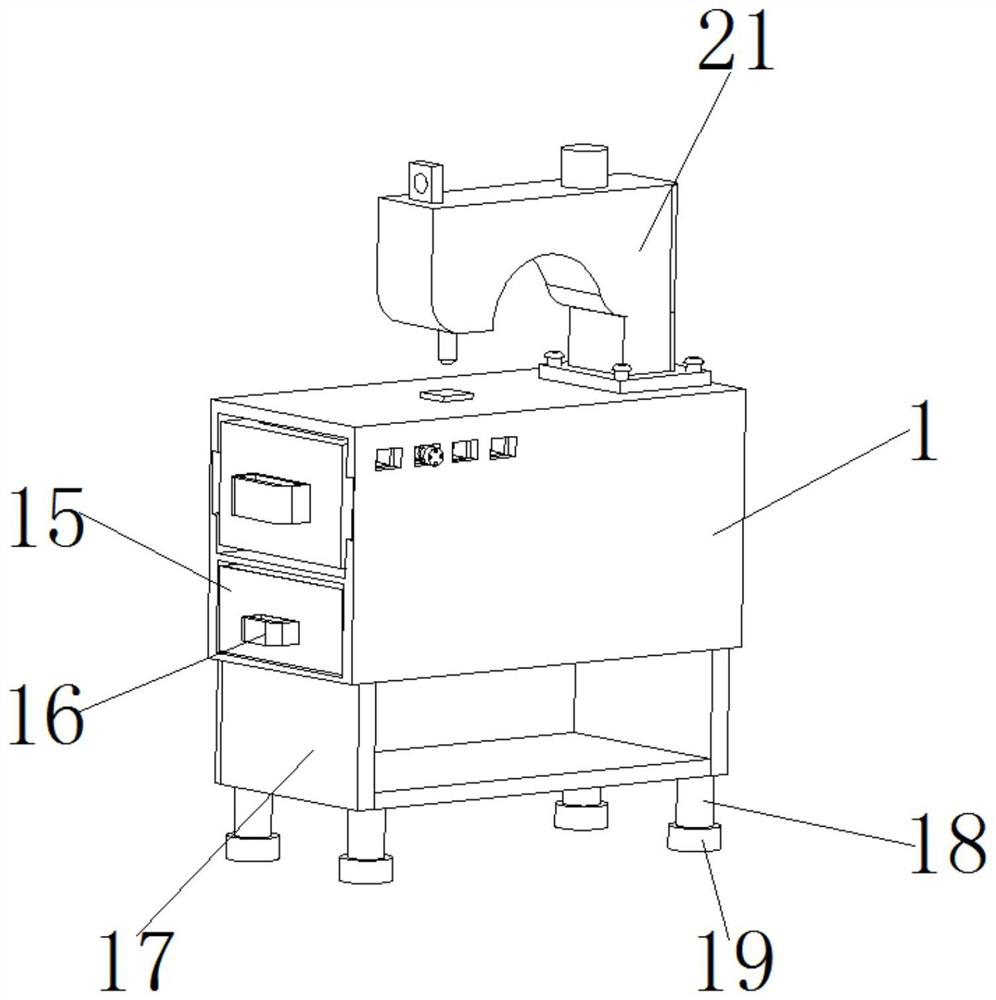

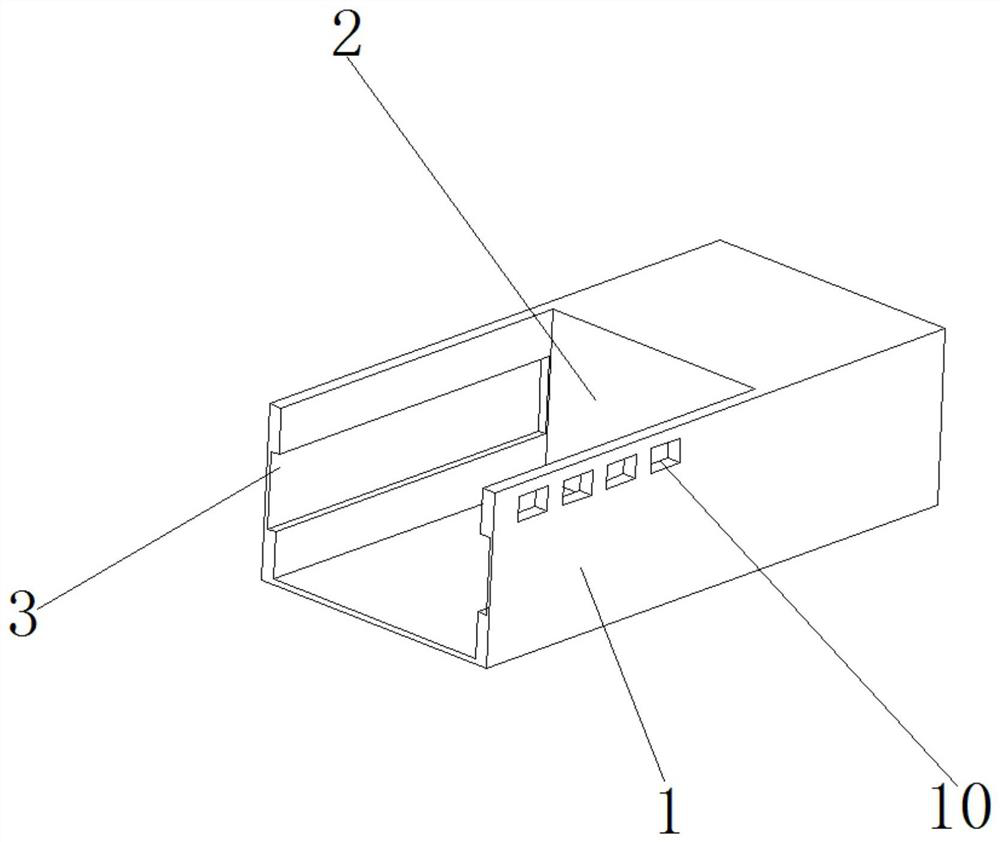

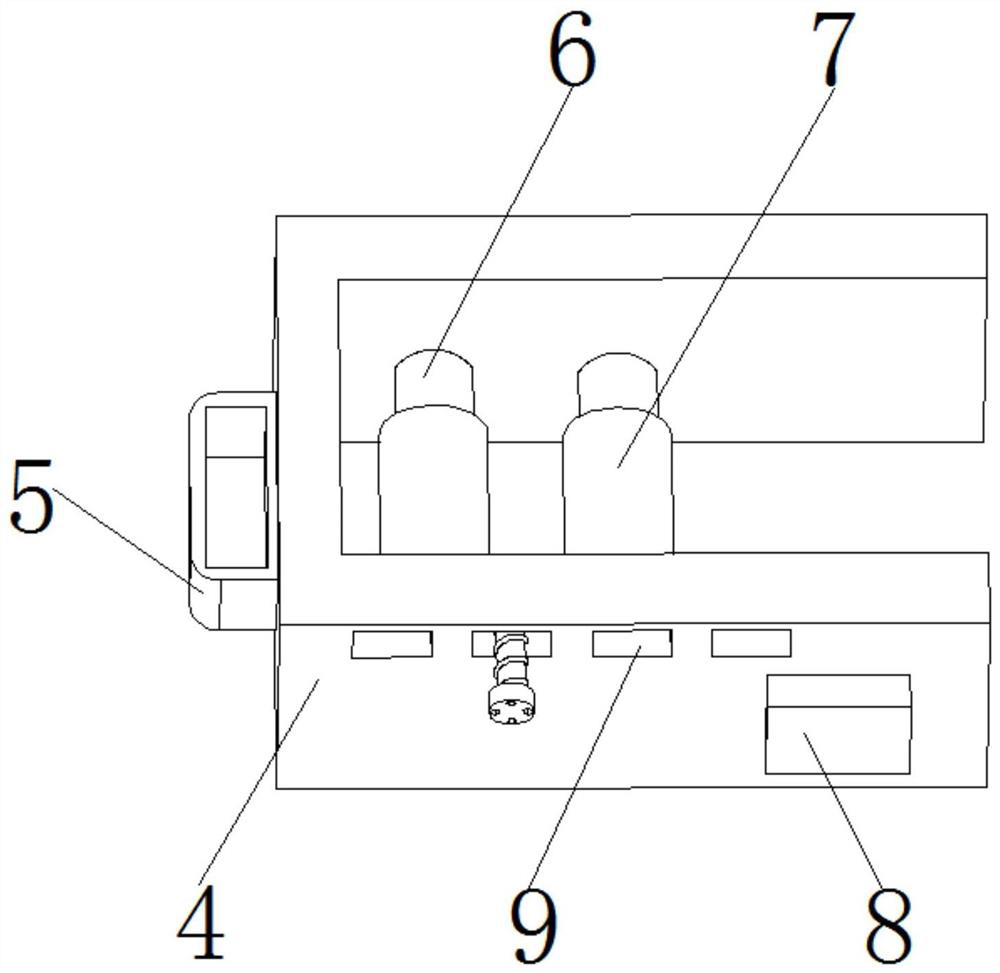

[0028] Example 1, such as Figure 1-5 As shown, a curtain producing a curtain produces a sewing machine, including a bottom plate 1, and the upper end of the bottom plate 1 is opened, and the central portion of the surface of the mounting groove 2 is opened, and each of the slots 3, each slide 3 The inner side surface is provided with a slider 8, and each slider 8 is provided with a rack 4, and one end of the interior of the display frame 4 is fixedly mounted having a fixed shaft 6, and each fixing shaft 6 is provided with a fixed roller 7, a display frame. 4 One side surface of the side surface is fixedly mounted, and the display frame 4 is fixed to each slider 8 side surface, the display frame 4 is not in contact with the interior surface of the mounting groove 2, each fixing roller 7 and each fixing shaft 6 activity Socket, no contact between each fixing roller 7, the lower end surface of the bottom plate 1 is fixed to the placement cabinet 17, the placement cabinet 17 is smalle...

Embodiment 2

[0029] Example 2, such as Figure 1-5 As shown, the upper end of the display frame 4 is opened, and a plurality of first restrictive grooves 9 are opened. The upper end of the bottom plate 1 is opened with a second restricted groove 10 equal to the first restricted groove 9, each of the first restricted grooves 9. There is a limited bit block 11 in which the second restricted slot 10 is provided, and the middle portion of the limit block 11 is fixedly mounted, and the connection rod 12 is attached to the surface of the connection rod 12, and the connection rod 12 is fixedly mounted. 14. Each of the first restricted grooves 9 is fastened by the limit block 11 after the limit block 11, by the limit block 11, by opening the first restricted groove 9 at the upper end of the display frame 4, by the upper end of the bottom plate 1 The second limit slot 10 is opened. When each of the first restricted grooves 9 is in the same plane with each of the second restricted grooves 10, by pulling ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com