Two-gear variable-speed-ratio RV speed reducer

A technology of reducer and variable speed ratio, which is applied in vehicle gearboxes, multi-ratio transmissions, transmissions, etc., can solve the problems that cannot meet the needs of industrial robots and AGVs with small speed ratio switching, and restrict the performance of robots and AGVs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

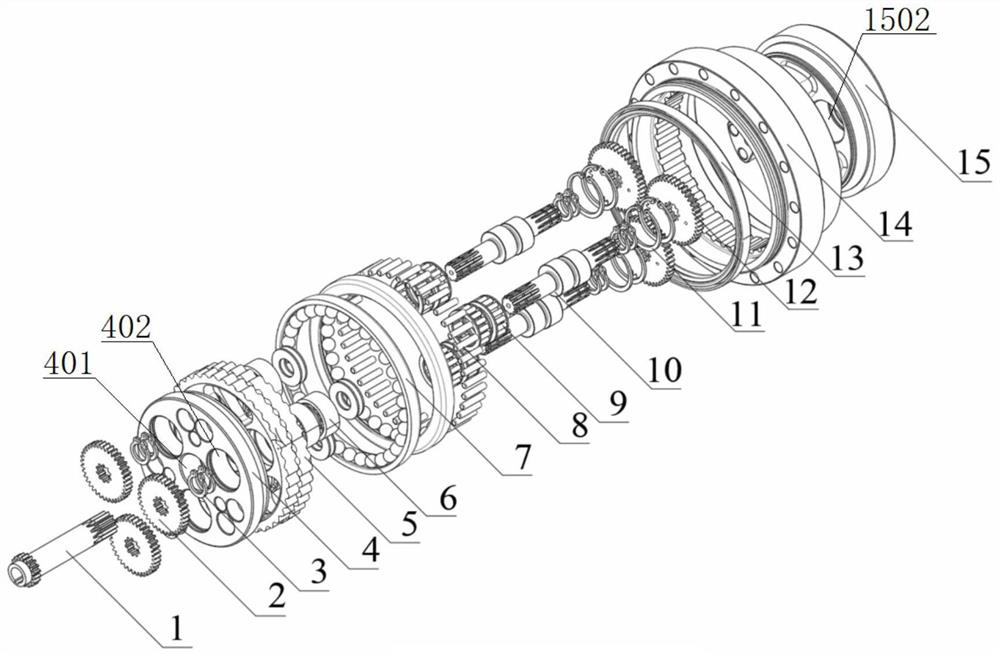

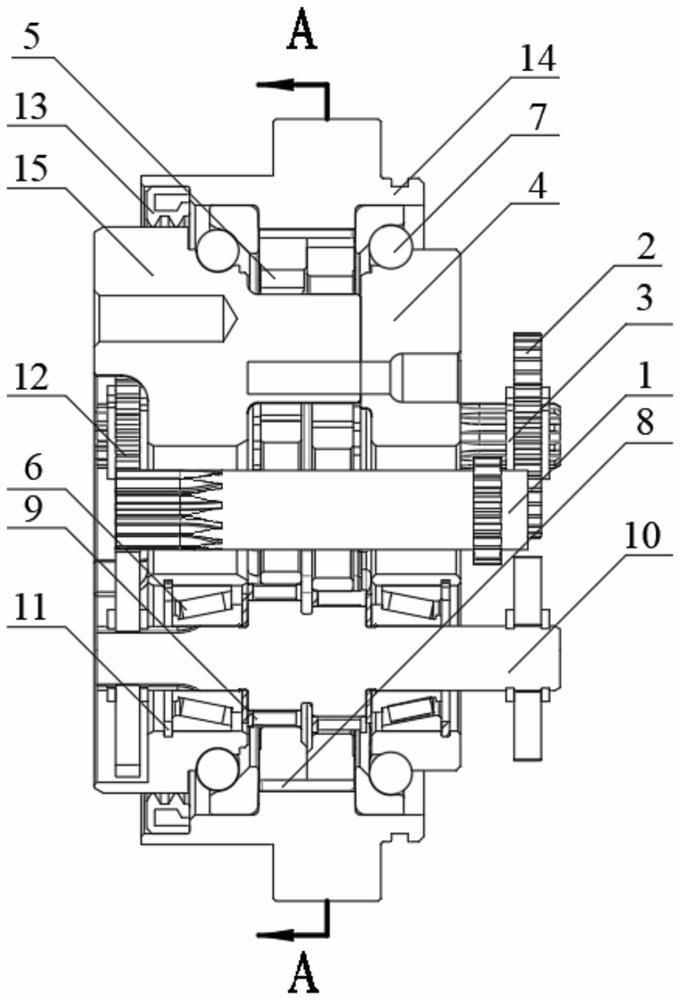

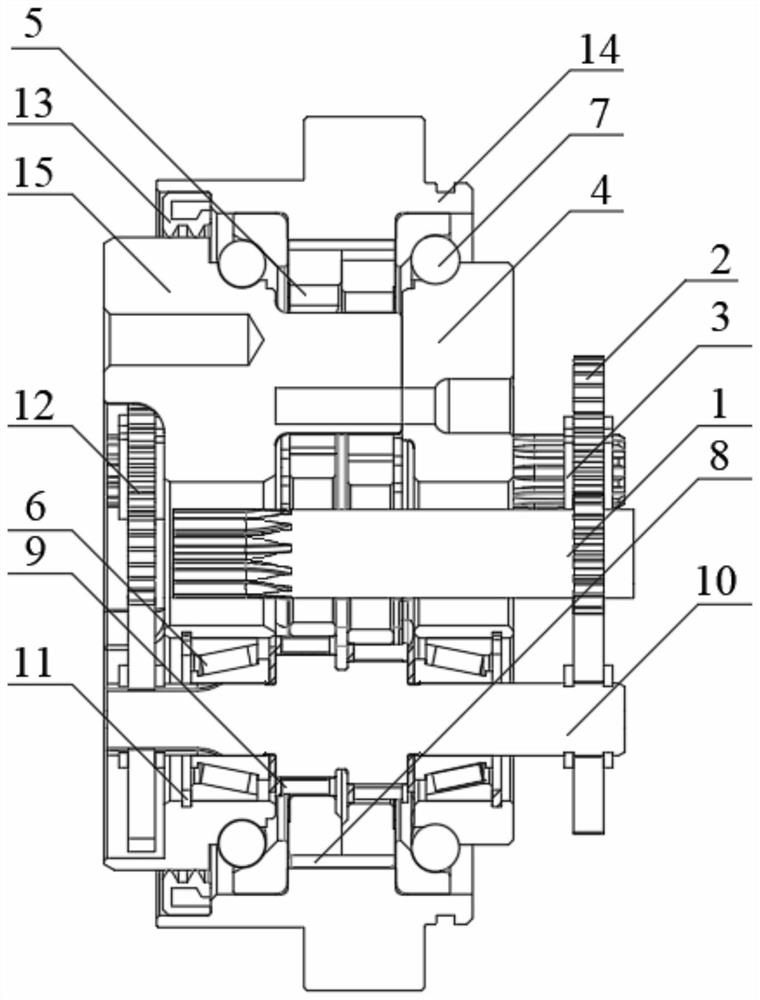

[0034] This embodiment discloses a two-speed ratio RV reducer, see Figure 1 to Figure 3 , including an input gear shaft 1, a pressure disc 4, two cycloidal wheels 5, two angular contact ball bearings 7, three crankshafts 10, and a pin gear housing 14 and an output disc 15.

[0035] The inner wall of the pin tooth housing 14 is uniformly inlaid with a plurality of pin teeth 8, forming an annular pin tooth group.

[0036] see Figure 4 , the two cycloidal wheels 5 are all meshed with the annular pin-tooth set, and the two cycloidal wheels 5 and the annular pin-tooth set form a planetary gear transmission mechanism with a tooth difference and a small tooth difference. The center of each cycloidal wheel 5 has a through hole I501. Each cycloidal wheel 5 has three bearing holes 502 evenly distributed on the circumference in the circumferential direction, and a needle bearing 9 is installed in each bearing hole 502 . A connection hole 503 is processed between two adjacent bearing...

Embodiment 2

[0048] This embodiment provides a relatively basic implementation method, a two-speed ratio RV reducer, see Figure 1 to Figure 3 , including an input gear shaft 1, a pressure disc 4, two cycloidal wheels 5, three crankshafts 10, and a pin gear housing 14 and an output disc 15.

[0049] The inner wall of the pin tooth housing 14 is uniformly inlaid with a plurality of pin teeth 8, forming an annular pin tooth group.

[0050] see Figure 4 , the two cycloidal wheels 5 are all meshed with the annular pin-tooth set, and the two cycloidal wheels 5 and the annular pin-tooth set form a planetary gear transmission mechanism with a tooth difference and a small tooth difference. The center of each cycloidal wheel 5 has a through hole I501. Each cycloidal wheel 5 has three bearing holes 502 evenly distributed on the circumference in the circumferential direction, and a needle bearing 9 is installed in each bearing hole 502 . A connection hole 503 is processed between two adjacent bea...

Embodiment 3

[0060] The main structure of this embodiment is the same as that of Embodiment 2, further including two angular contact ball bearings 7 .

[0061] The two angular contact ball bearings 7 are respectively installed on both sides of the ring-shaped needle-tooth set, and perform circumferential positioning on the ring-shaped pin-tooth set and the two cycloidal wheels 5 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com