Acoustic emission simulation method and system based on discrete element method

A technology of acoustic emission simulation and discrete element method, which is applied in the field of acoustic emission simulation, can solve the problems of high occupation of computing resources, poor authenticity, and inconsistency with the principle of simulated acoustic emission technology, and achieves saving computing time, high authenticity, and fast calculation speed. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0133] First, the acoustic emission test of shale under uniaxial compression was carried out, and the macroscopic mechanical parameters such as uniaxial compressive strength and Young's modulus of rock samples were obtained;

[0134] The experiment was reproduced by the discrete element software PFC. The size of the numerical calculation model is consistent with that of the rock sample, and the obtained stress-strain curve is as follows: Figure 5 As shown, the established numerical calculation model can reproduce the experimental process well;

[0135] Three monitoring points are evenly arranged in the axial direction and lateral direction of the surface of the model, respectively, with intervals of 20mm and 25mm, and are numbered 1-9 in turn. Such as Figure 6 shown.

[0136] Monitor the velocity waveform of 9 monitoring points;

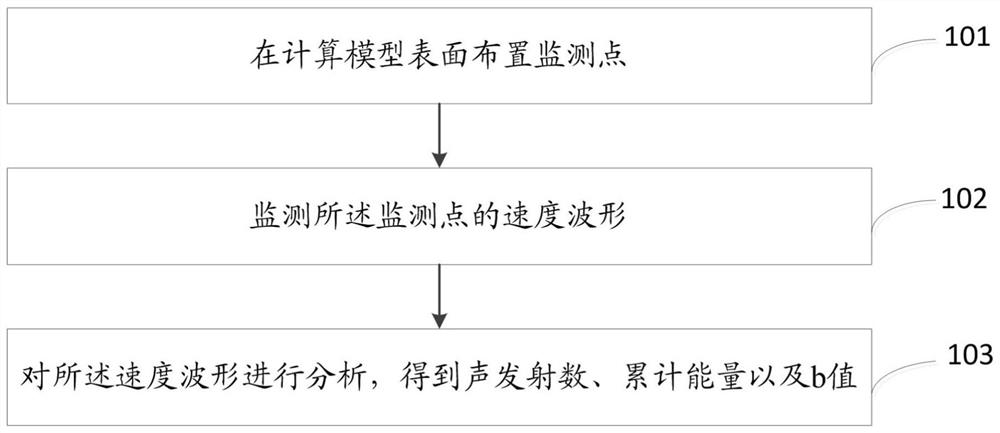

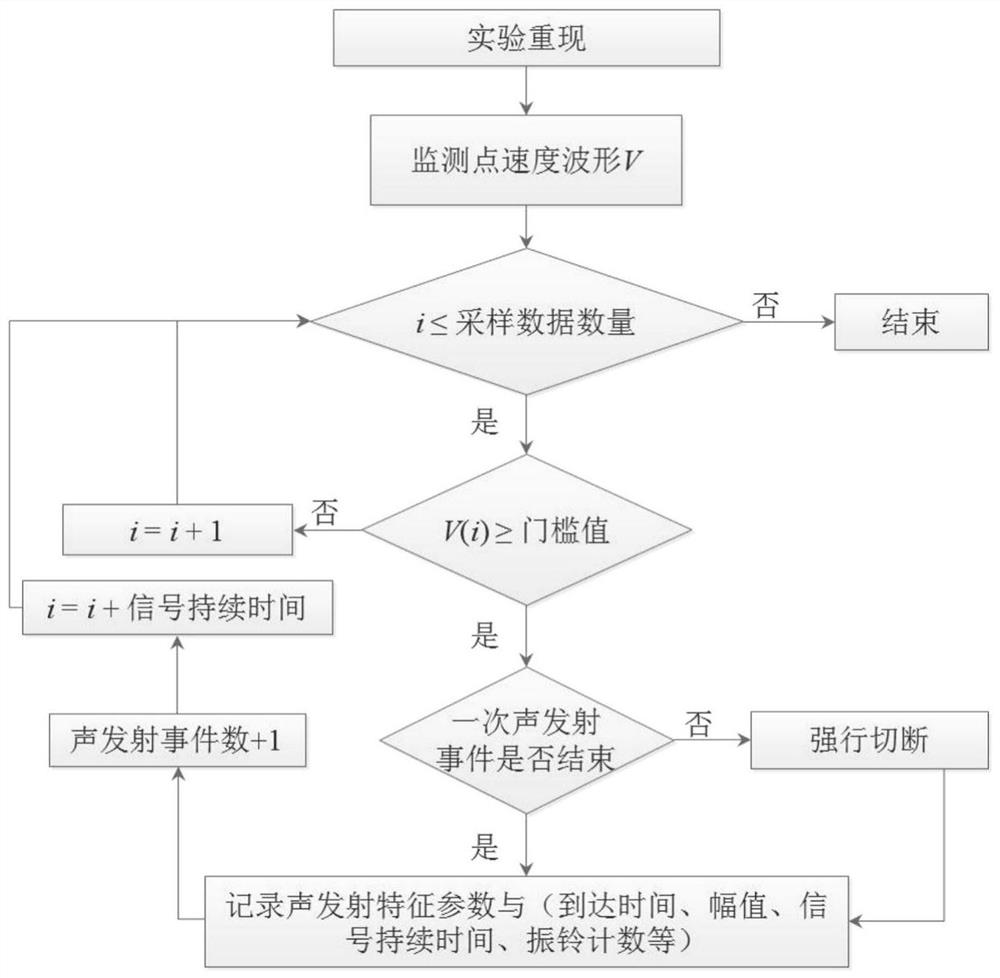

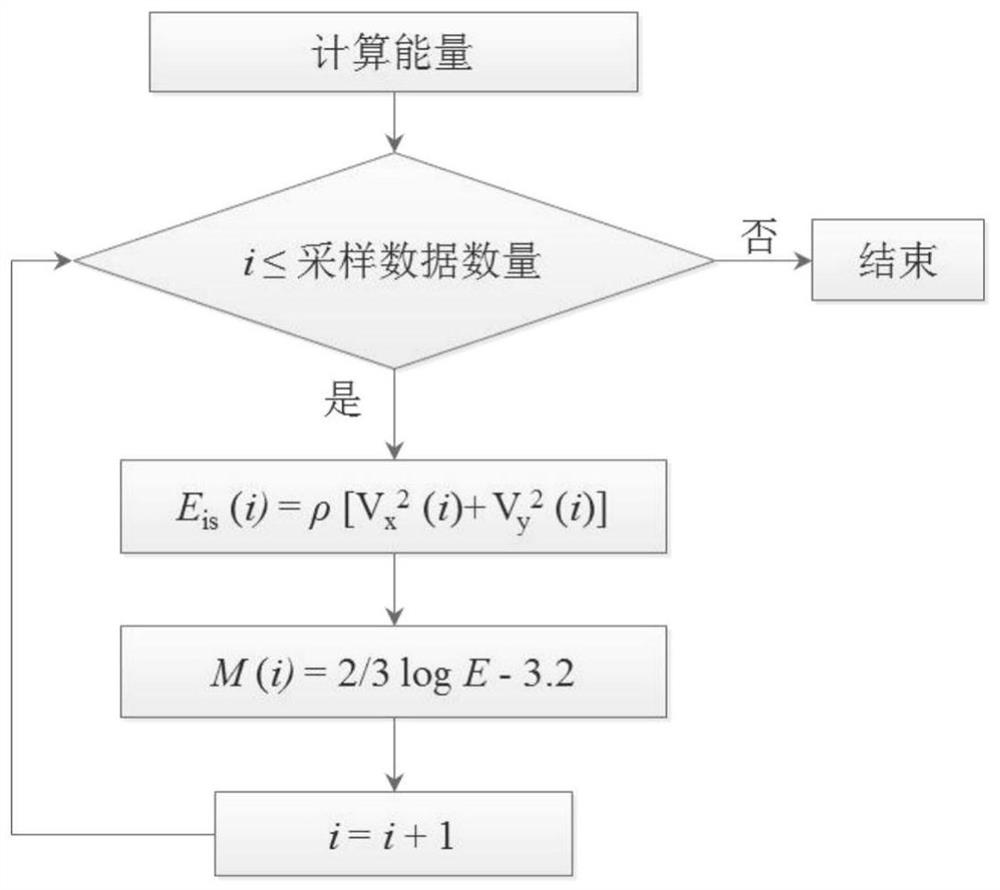

[0137] Analyze the velocity waveform to obtain the acoustic emission count, energy and b value, and take No. 2 monitoring point as an example ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com