Engineering quality acceptance method integrating information model and laser three-dimensional scanning technology

A technology of laser three-dimensional scanning technology, which is applied in the field of integrated information model and laser three-dimensional scanning technology engineering quality acceptance, can solve the problems of reduced accuracy of measurement results, low efficiency and accuracy, and cumbersome measurement process, so as to reduce accidents The probability, efficiency and accuracy are high, and the effect of improving the acceptance efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

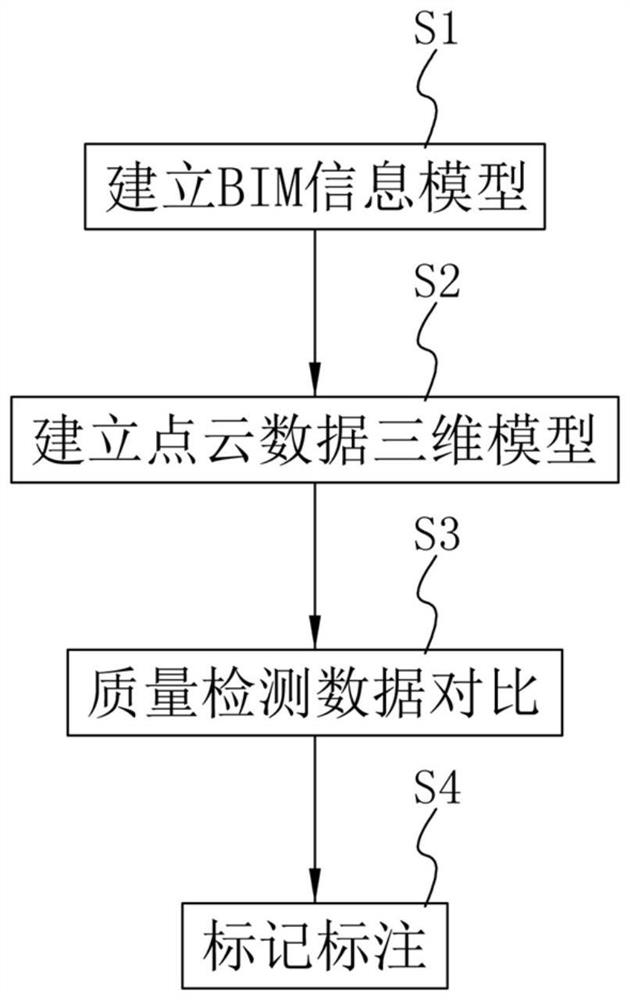

[0025] A method for engineering quality acceptance of an integrated information model and laser three-dimensional scanning technology, comprising the following steps:

[0026] S1. Establish BIM information model: use the design drawings as the information source to carry out BIM information modeling to obtain the BIM information model; use the modeling software Revit to carry out BIM information modeling for the quality inspection target, and integrate beams into the BIM information model , Geometric dimensions, materials, factory information, construction personnel, completion time information of slabs and columns;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com