Charging method for prolonging service life of lead-acid storage battery

A technology of lead-acid battery and charging method, which is applied in the direction of secondary battery charging/discharging, secondary battery, secondary battery repair/maintenance, etc., can solve problems such as potential safety hazards, high charging voltage, long charging time, etc., to prevent Gas evolution reaction, improve cycle life, and ensure the effect of charging capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

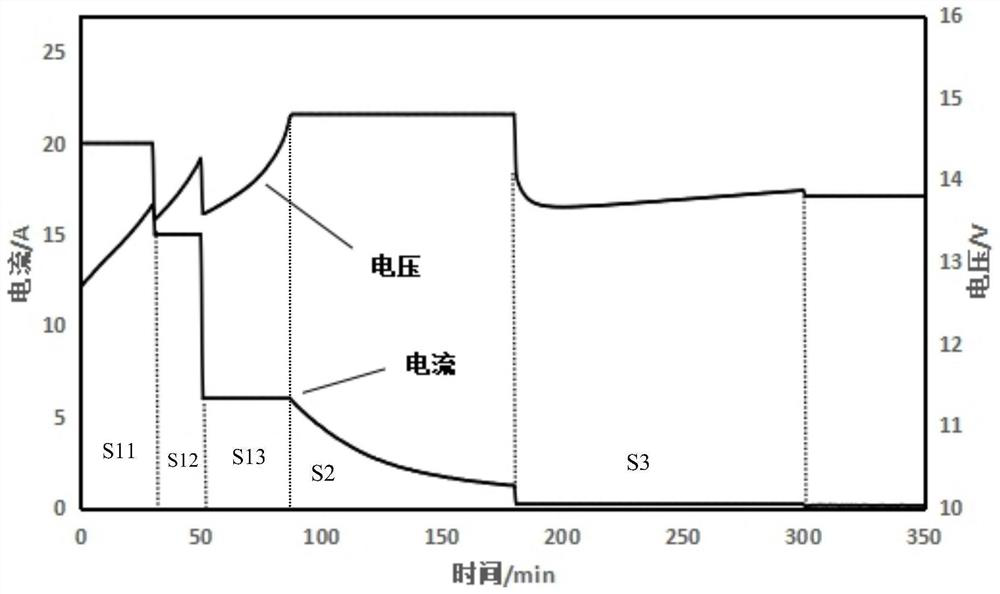

[0053] Embodiment 1 uses a battery with a capacity of 20Ah and a voltage of 12V.

[0054] The first constant current charging step S11: Charge to 13.5V / piece with 20A, and the charging time is 30min;

[0055] The second constant current charging step S12: Charge to 14.1V / piece with 15A, and the charging time is 20min; and

[0056] The third constant current charging step S13: continue to reduce the charging current, and charge it to 14.7V / piece with 6A;

[0057] Constant voltage charging stage S2: In the third constant current charging step, the charging voltage reaches 14.7V / piece and then constant voltage charging, the charging time of the third constant current charging step and the constant voltage charging stage is 130min, and the transfer condition is 0.5A;

[0058] Float charge stage S3: limited current 0.2A, 13.8V / float charge only for 3h, carried out after 10 cycles of the constant current charge stage and the constant voltage charge stage.

[0059] The charging vol...

Embodiment 2 Embodiment 3

[0062] What embodiment 2 to embodiment 3 adopt is the battery of capacity 20Ah voltage 12V.

[0063] The method steps in Embodiment 2 to Embodiment 3 are exactly the same as those in Embodiment 1, and only the parameters are different. The different parameters are shown in Table 1, and will not be repeated here.

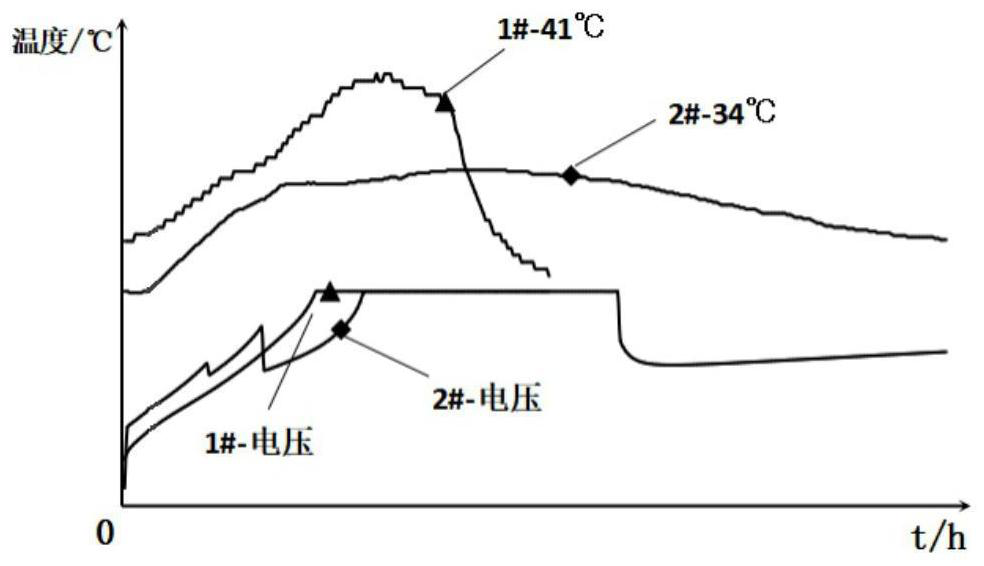

[0064] Embodiment one to embodiment three and comparative example one, comparative example two cycle test graphs see Figure 4 .

[0065] Embodiment four to embodiment six

[0066] Embodiment 4 to Embodiment 6 are charging curve systems for batteries with a corresponding capacity of 12Ah and a voltage of 12V. The method steps are completely consistent with the method steps in Embodiment 1. Only the parameters are different. The different parameters are shown in Table 1, and will not be repeated here. repeat. According to this method of charging, the cycle life is more than 560 times;

[0067] Embodiment seven to embodiment nine

[0068] Embodiment 7 to Embodimen...

Embodiment 10 Embodiment 15

[0070] Embodiment 10 to Embodiment 15 are 3 batteries corresponding to capacity 12A, 20Ah, 200Ah and voltage 12V to form a 36V battery pack and 5 batteries corresponding to capacity 12A, 20Ah and 200Ah and voltage 12V to form a 60V battery pack. The steps of the method are exactly the same as the steps of the method in Embodiment 1, only the parameters are different, and the different parameters are shown in Table 1, and will not be repeated here. According to this method of charging, the cycle life is more than 540 times.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com