Atomizer with ultrasonic atomization sheet vertically placed

A vertically placed, atomizing sheet technology, applied in the direction of tobacco, etc., can solve the problems of long e-liquid conduction time, prone to scorching, and more e-liquid in the atomization cavity, so as to reduce the time of e-liquid conduction, fogging and other problems. The effect of sufficient gasification and timely supply of e-liquid

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

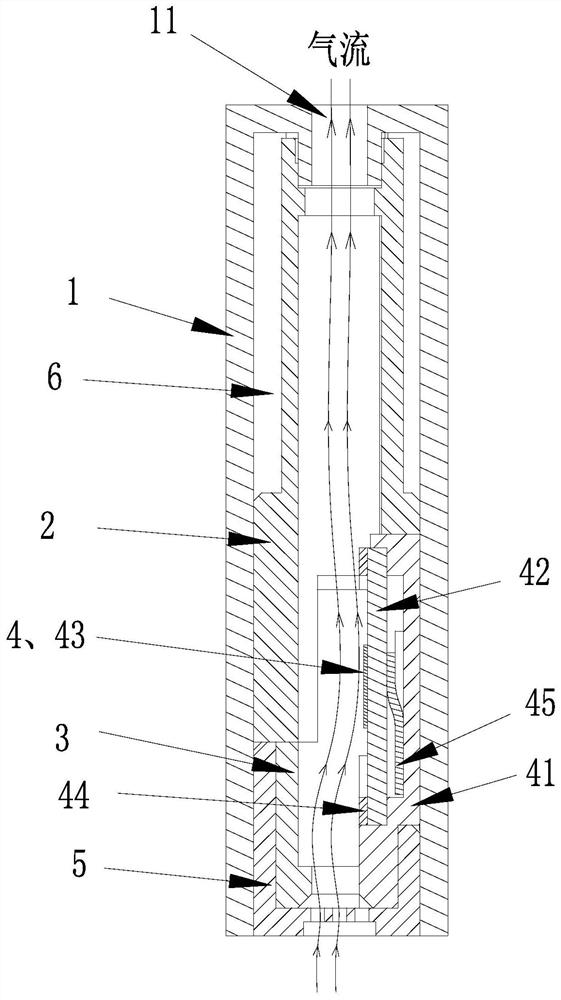

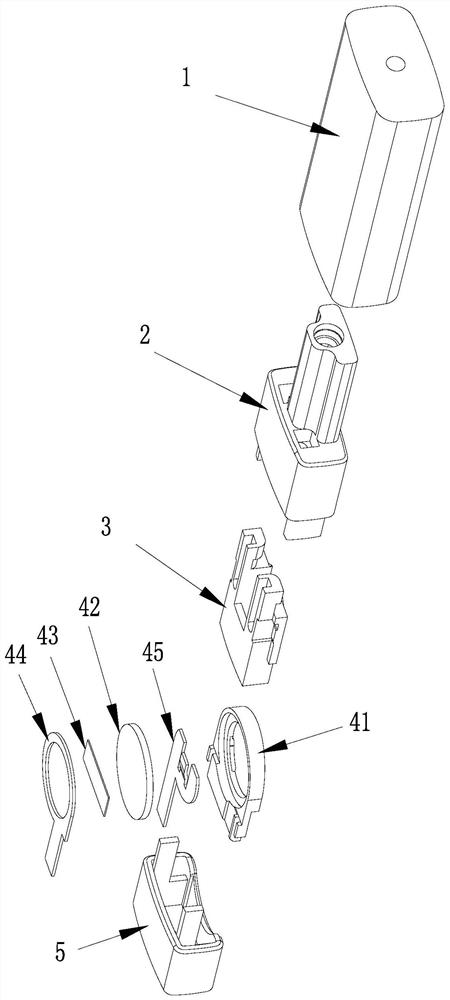

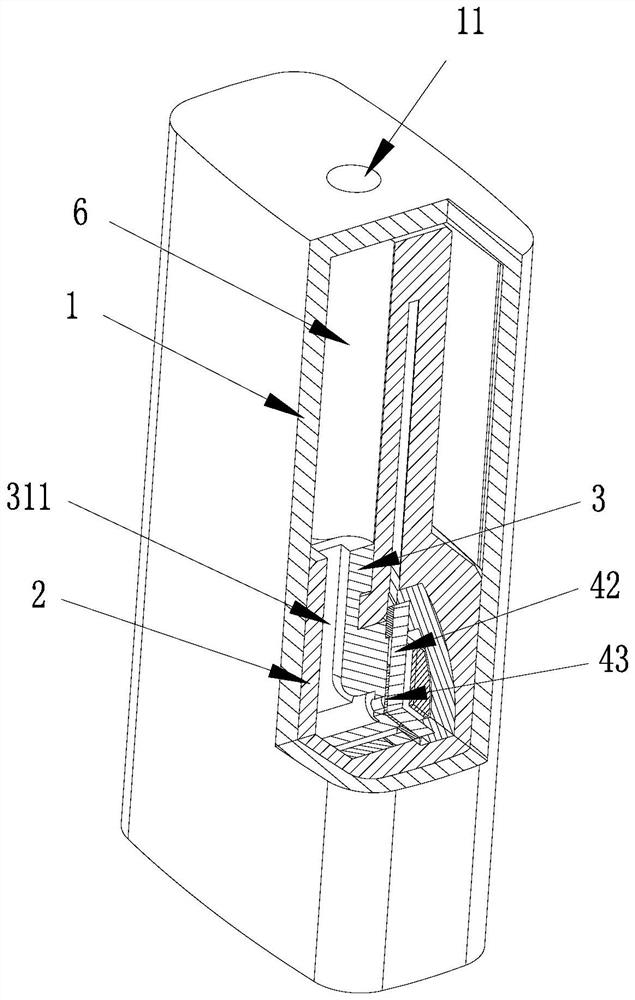

[0037] Such as Figure 1 - Figure 10 As shown, an embodiment of the electronic smoke device of the present invention includes an outer casing 1, an atomizing sleeve 2, a conductive bracket 3, an atom core 4, and a base 5.

[0038] The sucking nozzle 11 when smoking is provided on the outer casing 1.

[0039] The atomizing sleeve 2 is divided into the upper segment 21 and the lower section 22, and the cross-sectional area of the upper section 21 is smaller than the cross-sectional area of the lower section 22, and the atomization sleeve 2 is in the outer casing 1, so that the upper outer wall of the atomizing sleeve 2 and the outer casing 1 The top surface of the oil circle 6 is formed between the lower surface of the oil position, and two open port 221 is provided on the bottom surface of the oil bin. The middle portion of the upper section 21 is provided with a longitudinal gas pipe 211, and the top portion of the trachea 211 is in communication with the nozzle 11. Two sides 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com