Railway gondola car bottom door opening and closing buffer device

A bottom door opening and closing and cushioning device technology, which is applied to railway car body parts, funnel cars, transport passenger cars, etc., can solve the problems of increased labor intensity of operators, damage to the bottom door, and increased gap between bottom doors, etc., so as to avoid transition The effect of compression failure, reducing the impact force of opening and closing, and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

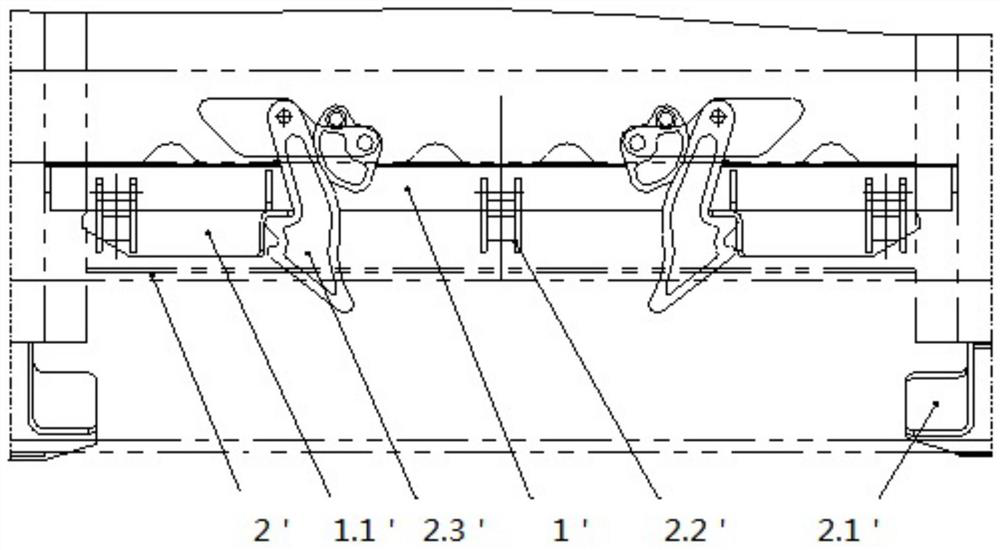

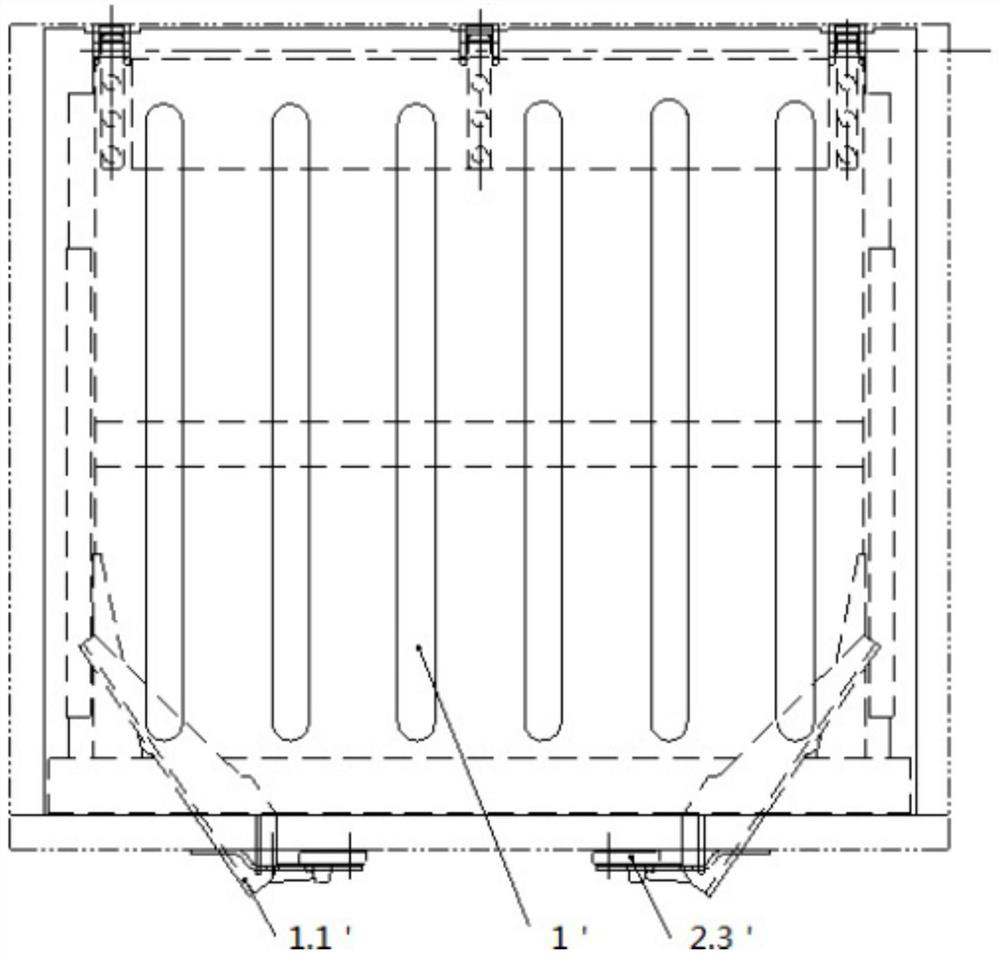

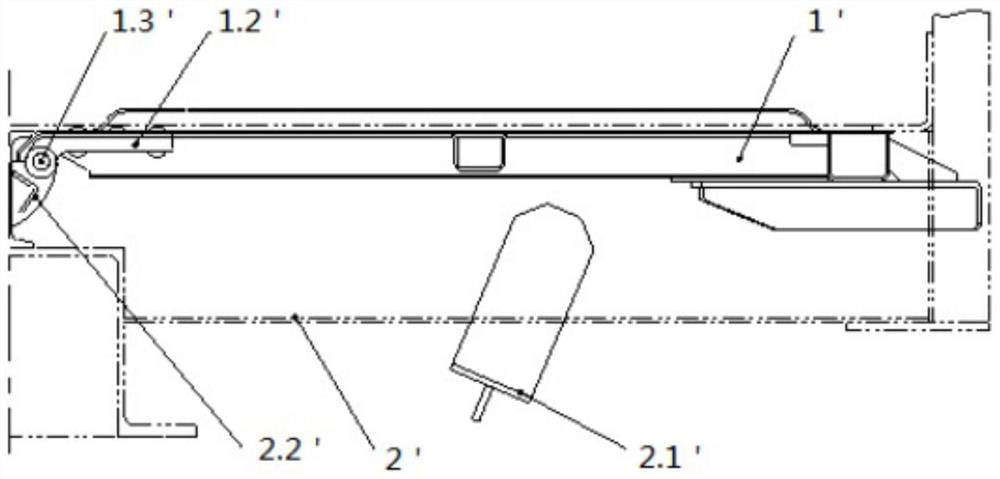

[0075] Such as Figure 1 to Figure 13 As shown, the present invention provides a bottom opening and closing buffer of a gondola, including:

[0076] Rod spring mechanism, torsion bar spring mechanism includes torsion bar spring 1, connecting rod 2, torsion bar spring 1 is U-shaped, one end of torsion bar spring 1 is connected with the bottom door of the railway gondola car, and the other end of torsion bar spring 1 is connected with the connecting rod One end of the connecting rod 2 is rotatably connected, and the other end of the connecting rod 2 is rotatably connected with the underframe of the railway open car;

[0077] Spring buffer structure, the spring buffer structure is arranged on the bottom door stopper of the bottom door of the railway gondola car, when the bottom door of the railway gondola car is opened, the spring buffer structure forms an elastic fit with the bottom door of the railway gondola car.

[0078] In this embodiment, a connecting seat 3 is provided on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com