Assembly type battery pack bracket of hoisting type battery replacing vehicle

A battery pack and hoisting technology, applied in the field of assembled battery pack brackets, can solve the problems such as tearing of the welding interface between the bracket and the connecting part, the locking structure cannot be used normally, and the normal power exchange and operation are affected. The effect of reducing operating costs, reducing failure rates, and reducing maintenance and replacement costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

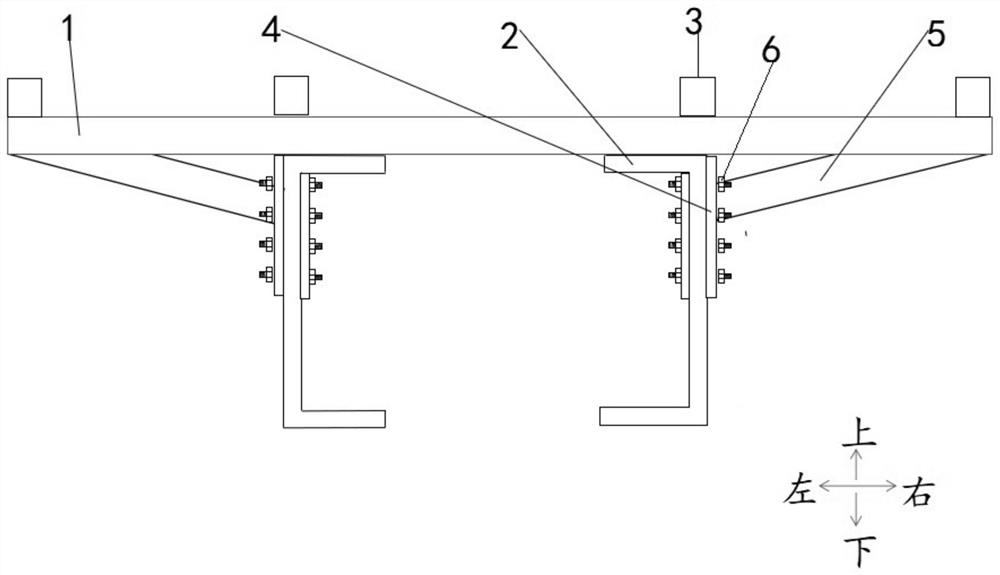

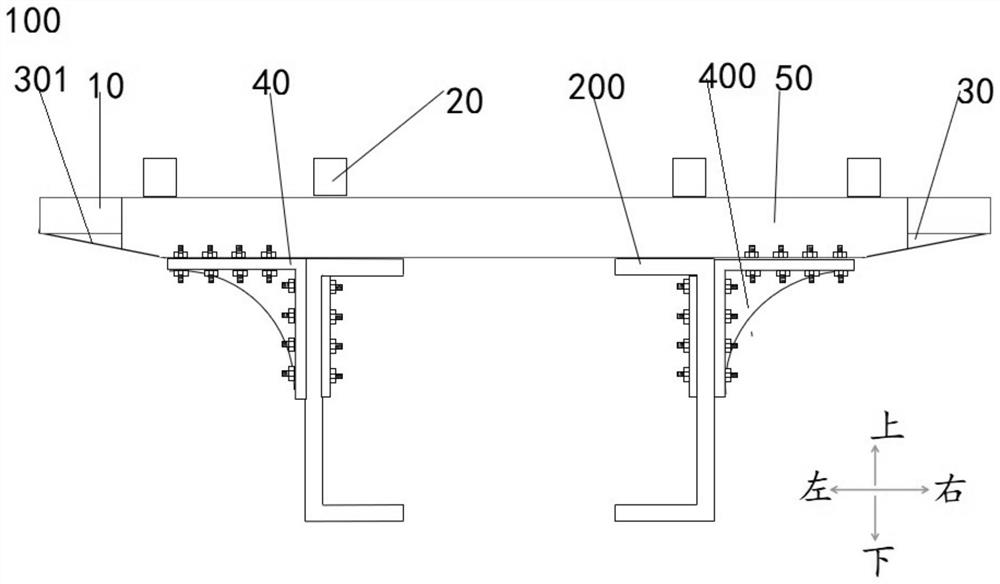

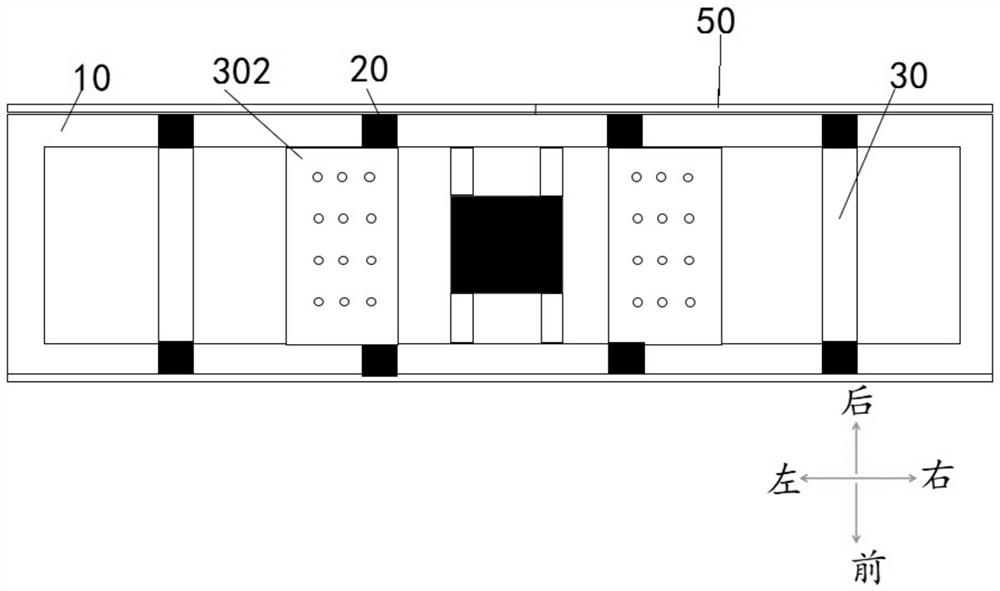

[0044] Such as Figure 2 to Figure 4 As shown, this embodiment proposes an assembled battery pack bracket 100 for a hoisting battery exchange vehicle. The battery pack bracket 100 includes a first body 10 , a battery pack lock 20 , a first reinforcing member 30 and a connecting member 40 , wherein the battery pack lock 20 is arranged on one side in the thickness direction of the first body 10 for fixing the battery pack; the first reinforcement member 30 is arranged on the other side in the thickness direction of the first body 10; the connecting member and the first reinforcement 30, and the first reinforcement 30 is connected to the large frame 200 of the hoisted battery swapping vehicle through the connecting piece.

[0045] To make it easy for those skilled in the art to understand, the length direction of the first body 10 is consistent with the left-right direction, the width direction is consistent with the front-rear direction, and the thickness direction is consistent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com