High-altitude component hoisting construction method

A construction method and component technology, applied to building components, building structures, walls, etc., can solve the problems of low hoisting efficiency of high-altitude components, fragile connection nodes, limited load-bearing capacity, etc., to avoid high-altitude operations, strengthen connection points, The effect of improving weight-bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052] In order to further explain the technical solutions of the present invention, specific examples are given below to illustrate in detail.

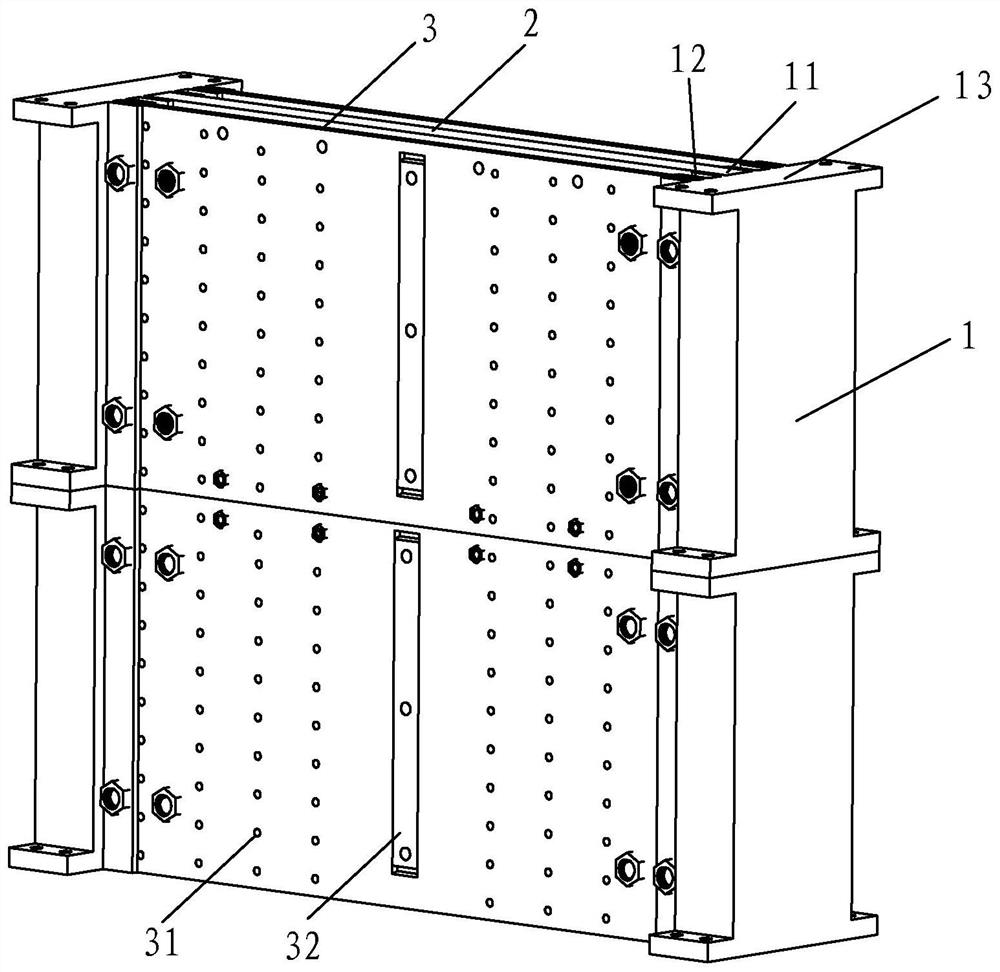

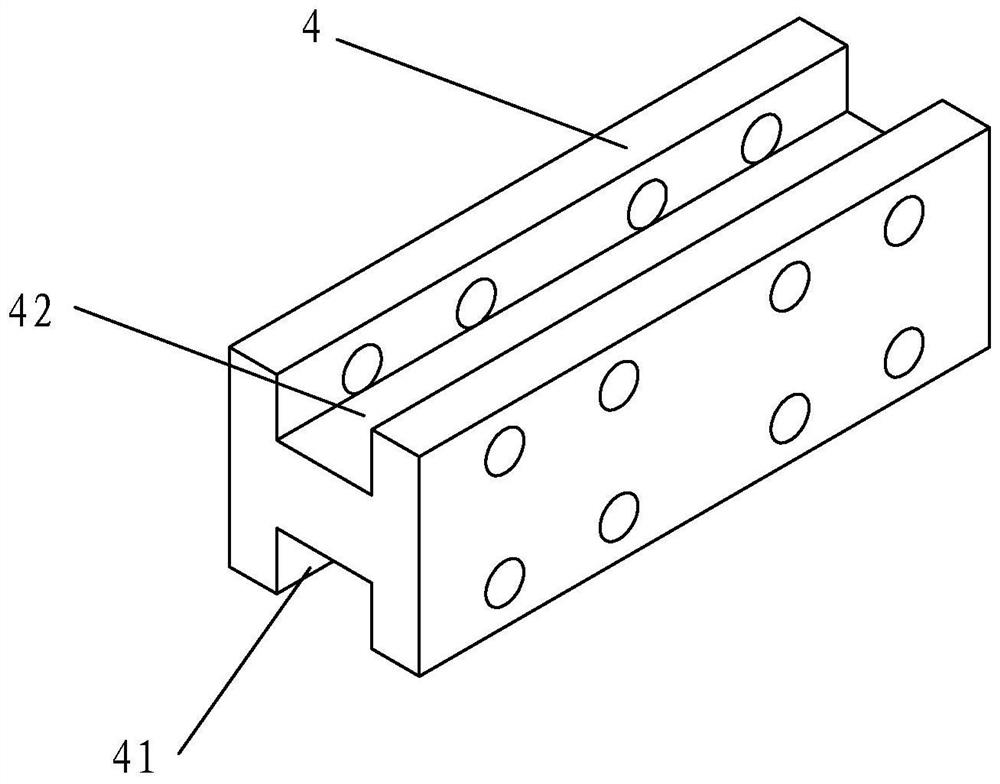

[0053] Such as Figure 1-4 Shown, a kind of high-altitude component hoisting construction method comprises the following steps:

[0054] S1: Set two steel structure columns 1 facing each other on the ground, vertically set the steel structure support ribs 2 between the two steel structure columns 1, and connect the steel structure support ribs 2 with the two steel structure columns 1 ;

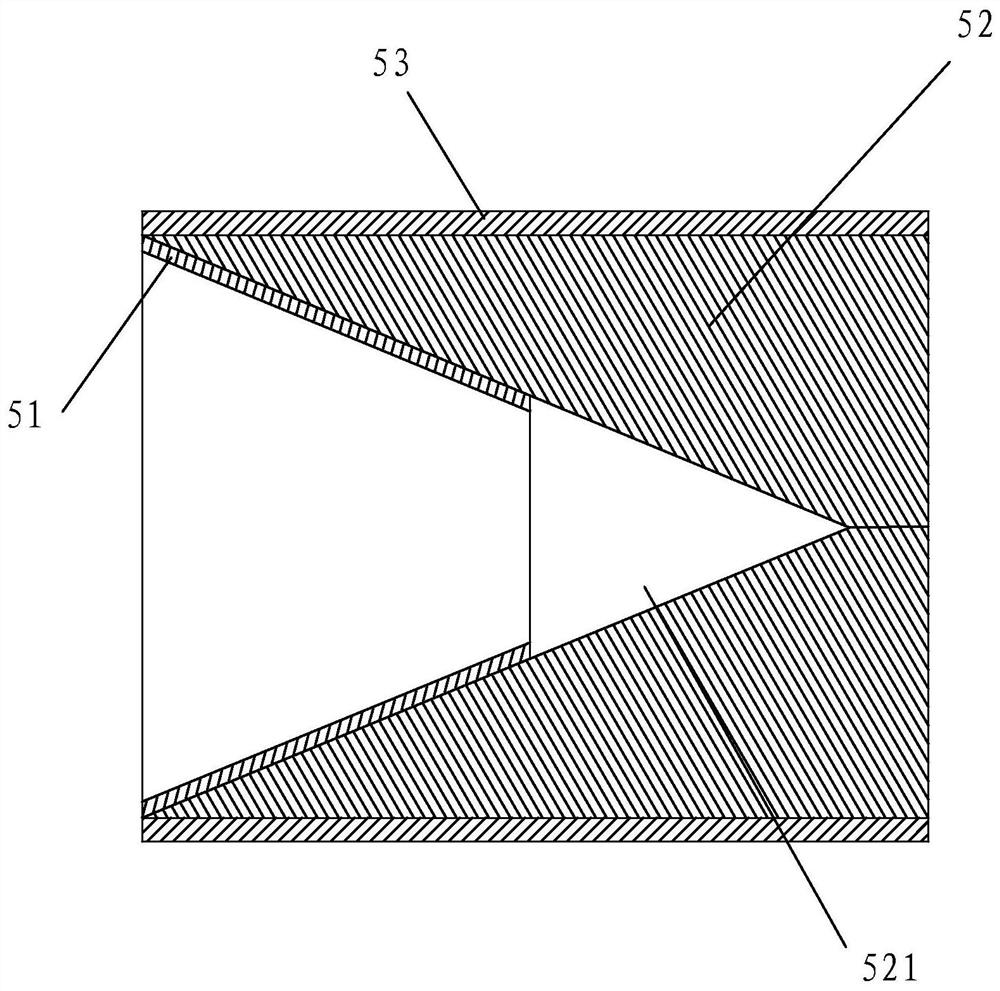

[0055] S2: Arranging the waterproof resin board 3 on both sides of the steel structure supporting rib 2, the waterproof resin board 3 is parallel to the steel structure supporting rib 2, and fixedly connected together by the first connecting device;

[0056] S3: connecting the waterproof resin board 3 and the steel structure column 1 together to form a storage space for the steel structure support rib 2;

[0057] S4: hoist the steel member mainly ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com