An anti-jamming drilling speed-increasing tool

A technology for preventing sticking and drilling, which is applied to drilling equipment, driving devices for drilling in wellbore, and earth-moving drilling, etc. It can solve problems such as increased drilling resistance, bit damage and failure, avoid torsional vibration, reduce Frictional resistance and life-enhancing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

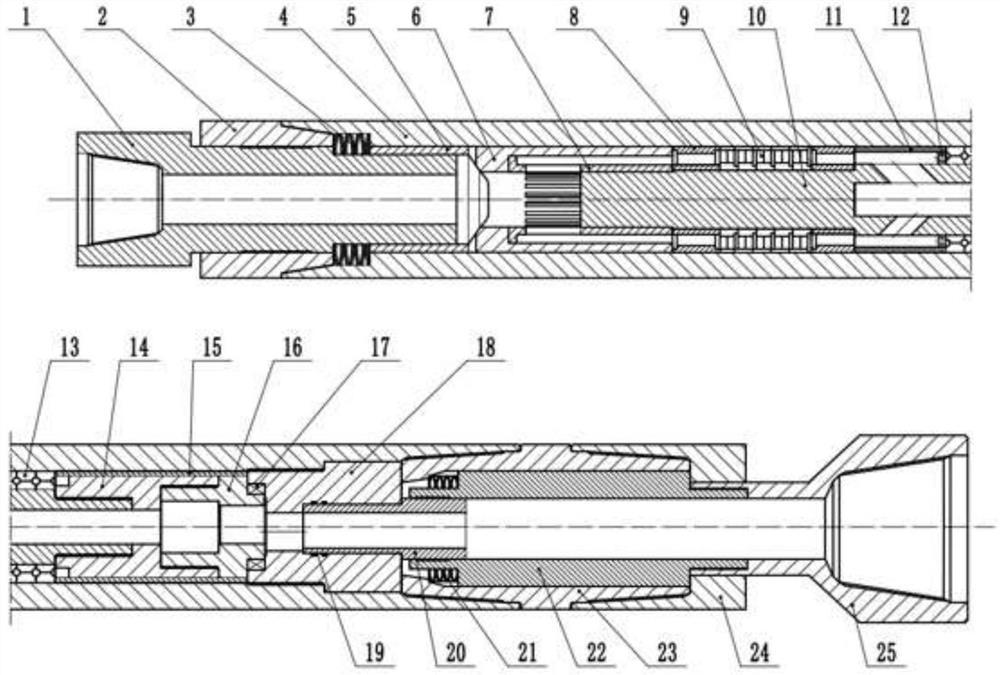

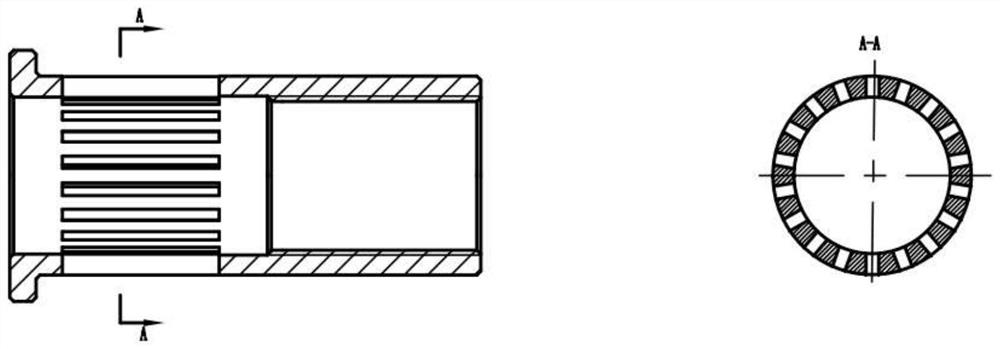

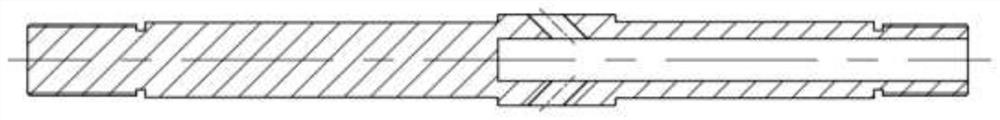

[0017] like Figure 1-5 As shown, an anti-jamming drilling speed-increasing tool, its structure mainly includes: sliding rod 1, upper joint 2, disc spring I 3, outer cylinder 4, force transmission sleeve 5, piston head cover 6, shunt element 7, rolling bearing 8. Turbine device 9, transmission shaft 10, adjustment ring 11, positioning cylinder 12, thrust bearing 13, transmission element 14, support cylinder 15, moving valve disc 16, bearing 17, fixed valve disc 18, sealing ring 19, valve disc Inner sleeve 20, disc spring II 21, hollow spindle 22, first lower shell 23, second lower shell 24, lower joint 25; its technical features are: upper joint 2, outer cylinder 4, first lower shell 23. The second lower housing 24 is threaded sequentially from top to bottom; the sliding rod 1 is installed in the inner hole of the upper joint 2 and the outer cylinder 4, and the clearance fits, and the sliding rod 1 and the upper joint 2 are connected by splines, sliding The lower end of the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com