Pump body assembly, compressor and air conditioner

A component and pump body technology, applied to pump components, machines/engines, liquid fuel engines, etc., to achieve the effects of reducing wear, reducing deflection, and extending service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

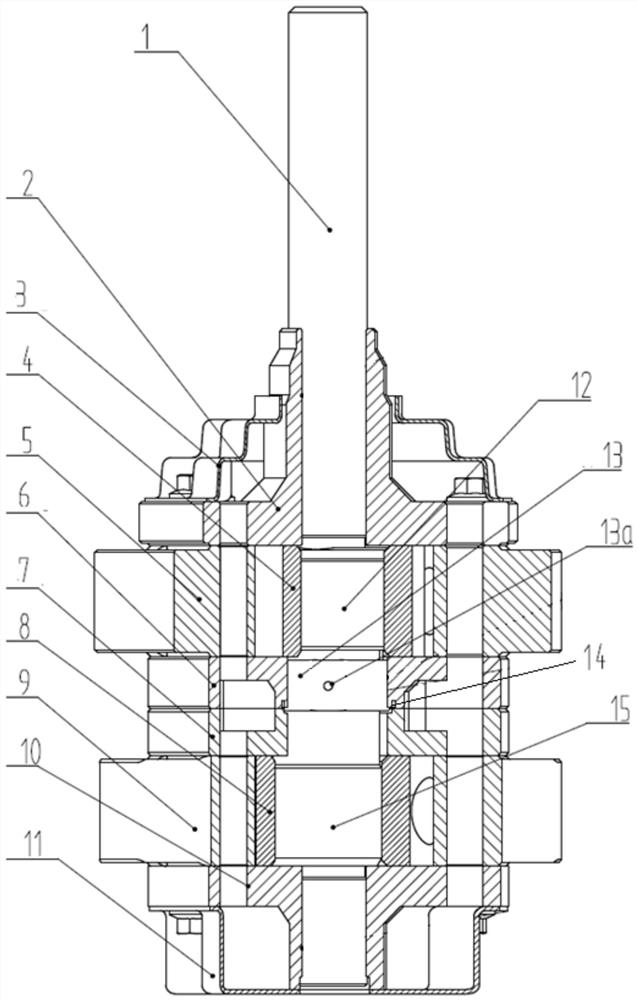

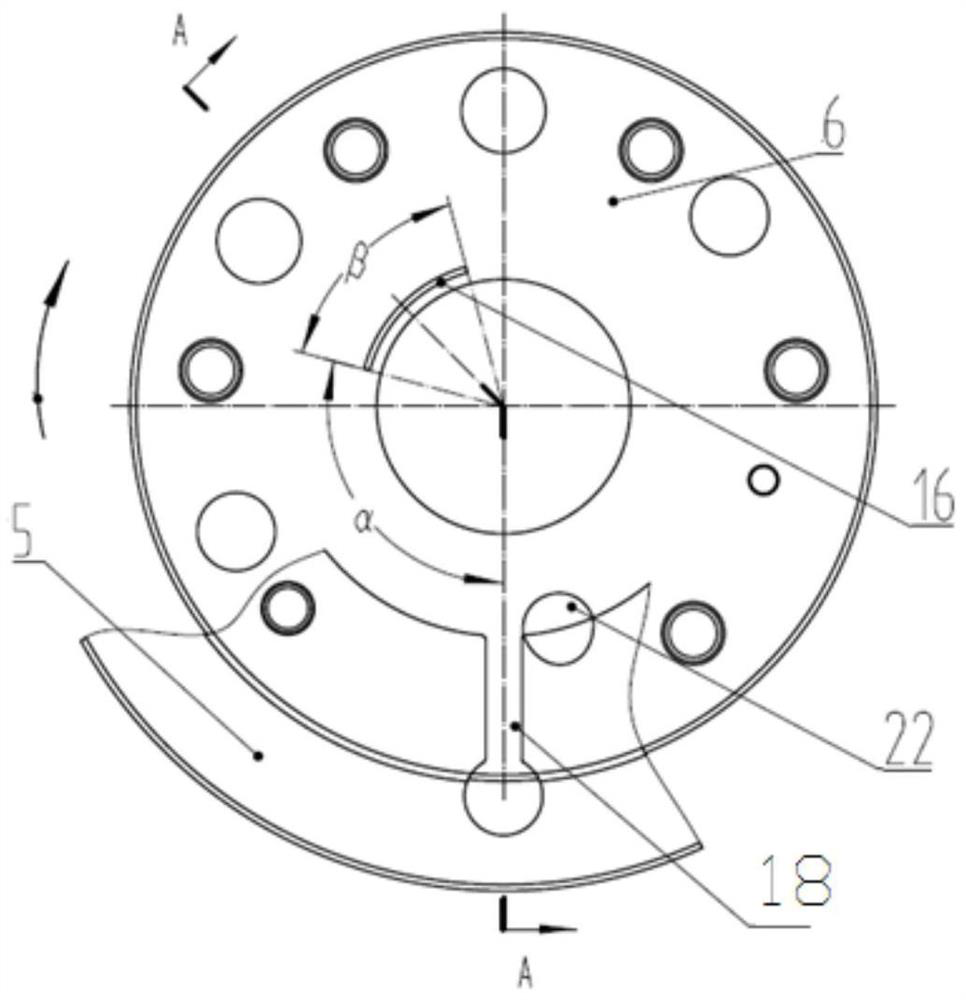

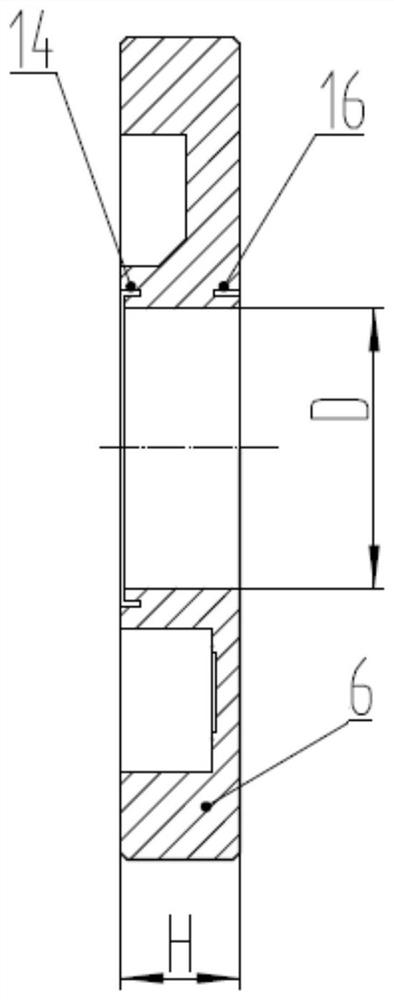

[0034] see in conjunction Figure 1 to Figure 9 As shown, according to the embodiment of the present application, the pump body assembly includes a crankshaft 1, and the crankshaft 1 includes a first eccentric portion 12 and a second eccentric portion 15 arranged axially at intervals, between the first eccentric portion 12 and the second eccentric portion 15 A first partition 6 and a second partition 7 are provided in sequence, the first partition 6 is provided with a first round hole 17, and a support shaft 13 is arranged in the first round hole 17, and the first partition 6 and the support shaft 13 A diaphragm bearing is formed, and the diaphragm bearing is provided with a stress relief structure that reduces contact stress between the support shaft 13 and the first diaphragm 6 .

[0035] The pump body assembly is provided with a diaphragm bearing, which can effectively support the middle part of the crankshaft 1 through the diaphragm bearing between the two eccentric parts,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com