Vibration reduction clamping type fixing device for mechanical equipment

A technology for mechanical equipment and fixing devices, which is applied in the field of vibration-damping clamp-mounted mechanical equipment fixing devices, can solve problems such as changes in the fixing strength of the fixing device, the inability to adjust the distance of the fixing device, and loose internal parts, etc., so as to increase practicability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

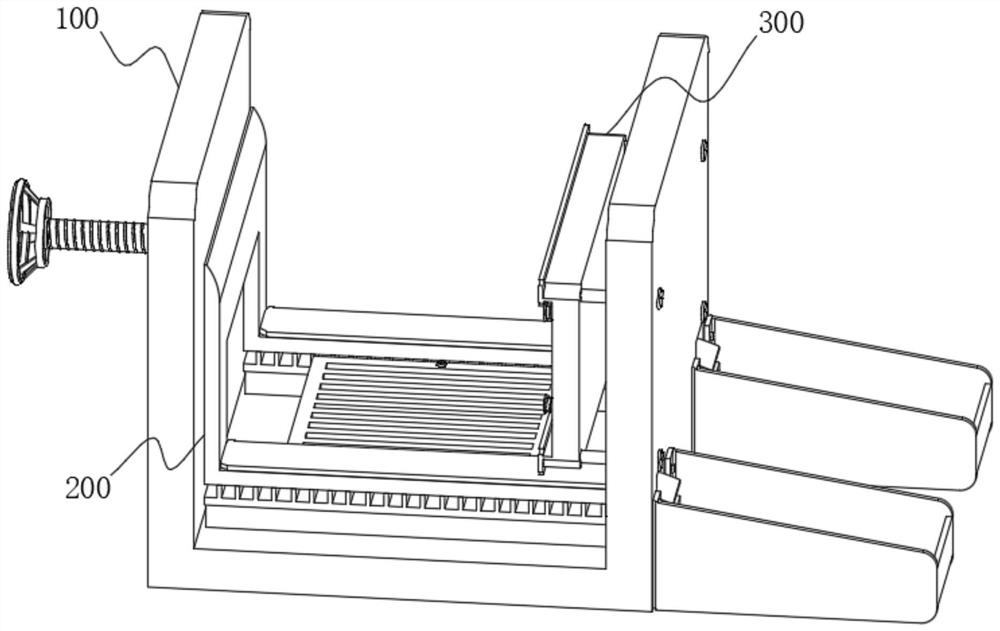

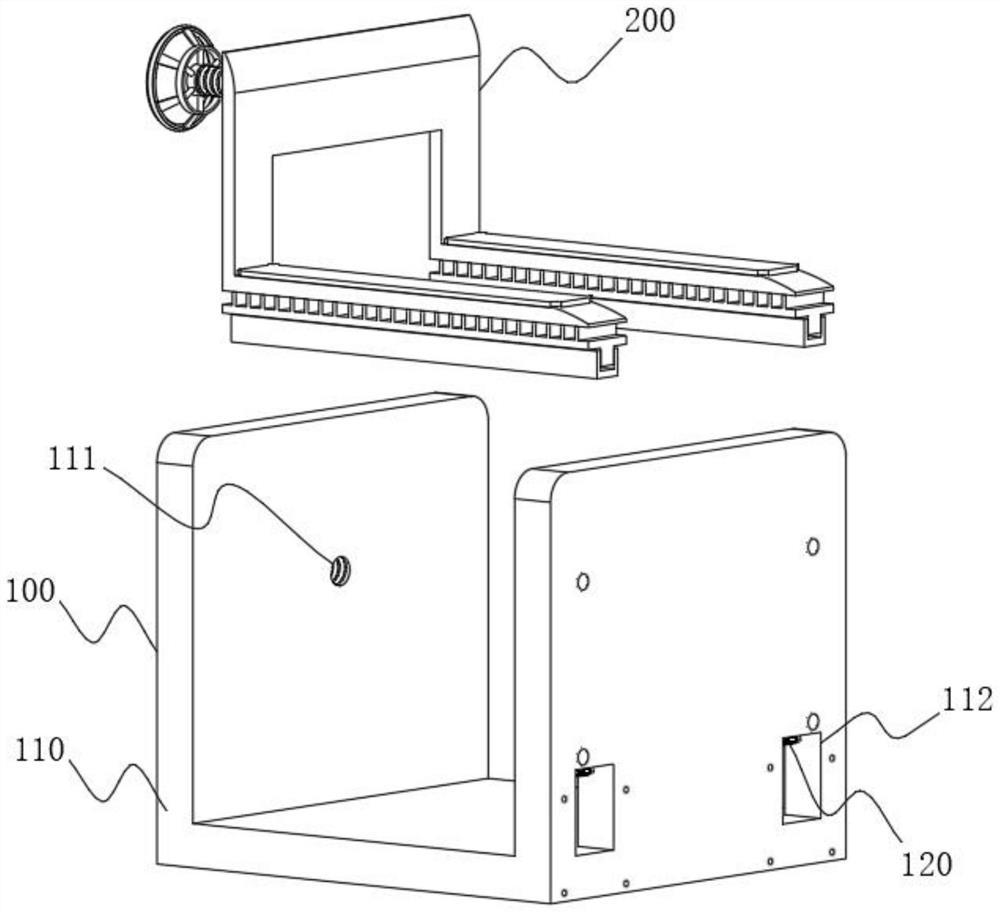

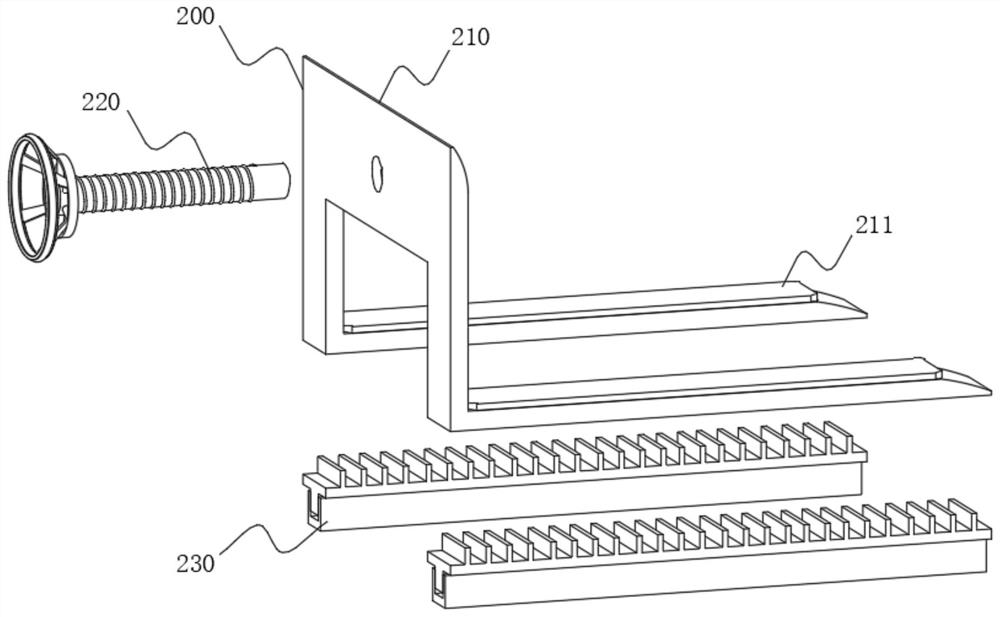

[0073] The present invention provides a vibration-damping clamp-mounted mechanical equipment fixing device, please refer to Figure 1-Figure 14 , including a supporting device 100, a distance adjusting device 200 and a vibration-damping clamping device 300 arranged on the opposite side of the distance adjusting device 200, the supporting device 100 includes a supporting frame 110, and the supporting frame 110 is a "U"-shaped plate, through which the supporting frame The left side wall of 110 supports the movable plate 310, and its right side wall supports the adjustment frame 210. The distance adjustment device 200 includes the adjustment frame 210. The adjustment frame 210 is an "L" shaped plate, and the bottom is hollowed out, forming two A placement plate with a width smaller than the right side wall of the adjustment frame 210, thereby reducing the area of the reserved groove 112 on the left side wall of the support frame 110, reducing the hollowing degree of the left sid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com