Method for detecting grouting saturation of inner sleeve of fabricated building wall and application thereof

A technology for grouting building walls and sleeves, which is used in measuring devices, material analysis using radiation diffraction, material analysis using wave/particle radiation, etc., can solve problems such as poor saturation methods, and achieve good applicability, Reliable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

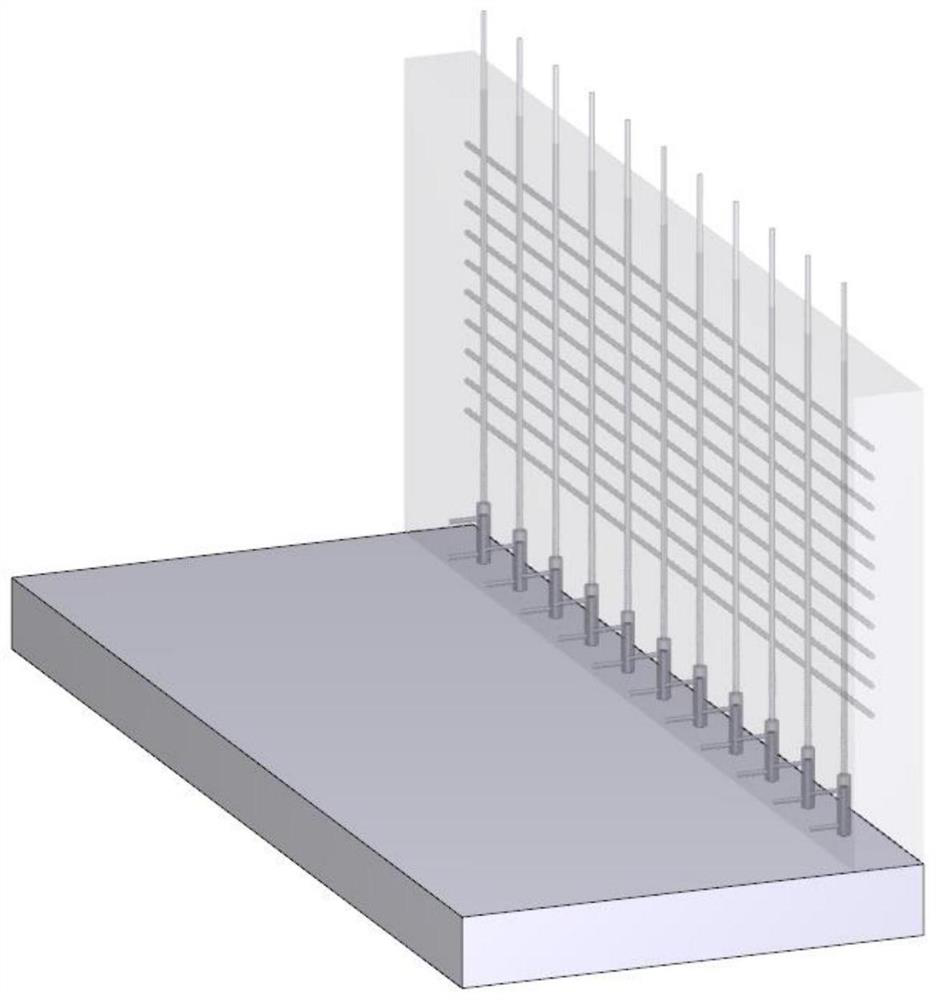

[0071] 1) Use the present invention for such as figure 1 The quality of the connection between the base plate and the wall shown is checked.

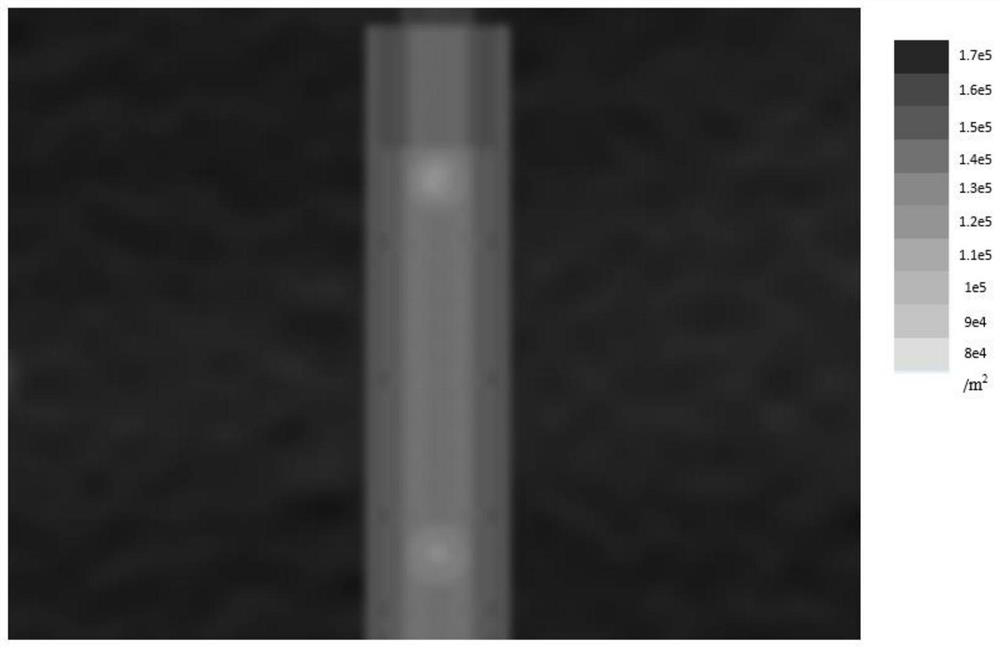

[0072] 2) The wall thickness d is 200mm. Use the neutron scattering imaging detector to calibrate and sample various parts of the wall sample plate with a thickness of 200mm, including the area A1 without any structure inside, and the area A2 containing standard sleeves and steel bars but no slurry inside, including standard sleeves Area A3 for cylinders, reinforcement and grout. Form a calibration image P A1 ( figure 2 ), P A2 ( image 3 ), P A3 ( Figure 4 ).

[0073] 3) As an implementation case, select figure 1 One of the connecting sleeves defines the detection area and divides the area 1 into an equally divided grid of N columns and M rows. Using a dedicated automated neutron scattering scanning imaging equipment, according to the equal grid step, the area is continuously automatically scanned to form {p NM}.

[0074]...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| degree of unsaturation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com