Laminate and packaging bag comprising same

一种层叠体、包装袋的技术,应用在运输和包装、包装、家用包装等方向,能够解决耐破袋性不足、易发生开裂等问题,达到不易破袋、耐热性优异、开封性优异的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

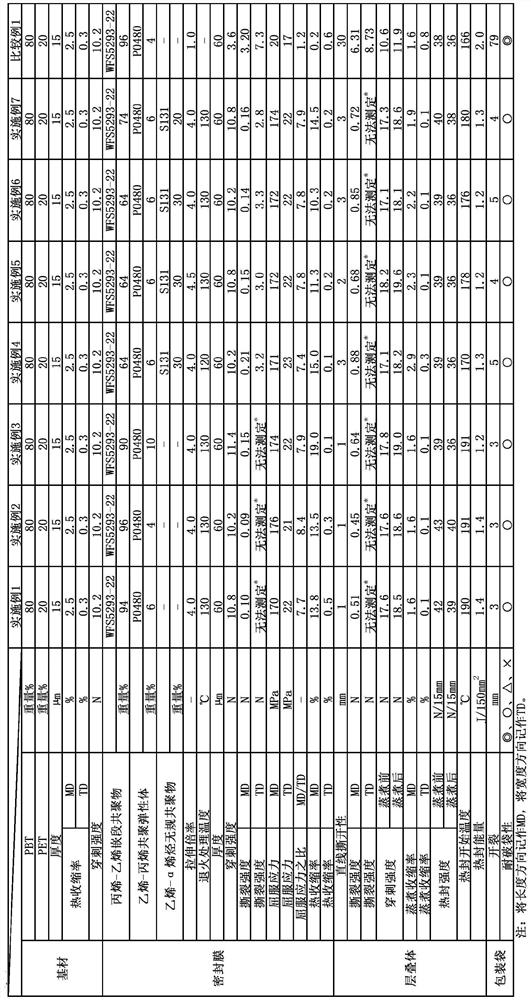

Embodiment 1

[0256] (Preparation of Biaxially Stretched PBT Film)

[0257] As PBT resin 1, 1100-211XG (CHANG CHUN PLASTICS CO., L width, intrinsic viscosity 1.28 dl / g) was used.

[0258] Using a single-screw extruder, mix 80 parts by mass of PBT resin and 20 parts by mass of PET with an intrinsic viscosity of 0.62 dl / g formed by terephthalic acid / / ethylene glycol=100 / / 100 (mol%) Resin, and porous silica particles having an average particle diameter of 2.4 μm as inactive particles so that the silica concentration was 1600 ppm, and after melting the obtained complex, the molten line was introduced into a 12-element static mixer. In this way, the melt of the PBT resin is divided and laminated, and a multilayer melt composed of the same raw material is obtained. The melt was cast from a T-die at 265° C., and the melt was bonded to a cooling roll at 15° C. by an electrostatic bonding method to obtain an unstretched sheet.

[0259] Then, 3.0-fold roll stretching was performed in the longitudin...

Embodiment 2

[0279] A laminate was obtained in the same manner as in Example 1, except that a propylene-ethylene block copolymer (manufactured by Sumitomo Chemical, WFS5293-22) and an ethylene-propylene copolymer elastomer (manufactured by Mitsui Chemicals, Tafmer P0480) were mixed The mixing ratio was set to 96% by weight of the propylene-ethylene block copolymer and 4% by weight of the ethylene-propylene copolymer elastomer (manufactured by Mitsui Chemicals, Tafmer P0480).

Embodiment 3

[0281] A laminate was obtained in the same manner as in Example 1, except that the mixing ratio of the propylene-ethylene block copolymer (manufactured by Sumitomo Chemical, WFS5293-22) and the ethylene-propylene copolymer elastomer was set to propylene- 90% by weight of an ethylene block copolymer, and 10% by weight of an ethylene-propylene copolymer elastomer (manufactured by Mitsui Chemicals, Tafmer P0480).

PUM

| Property | Measurement | Unit |

|---|---|---|

| heat shrinkage ratio | aaaaa | aaaaa |

| heat shrinkage ratio | aaaaa | aaaaa |

| yield stress | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com