Grain-oriented electrical steel sheet

一种电磁钢板、方向性的技术,应用在电路、磁性物体、磁性材料等方向,能够解决阻碍磁通密度、晶粒大等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach

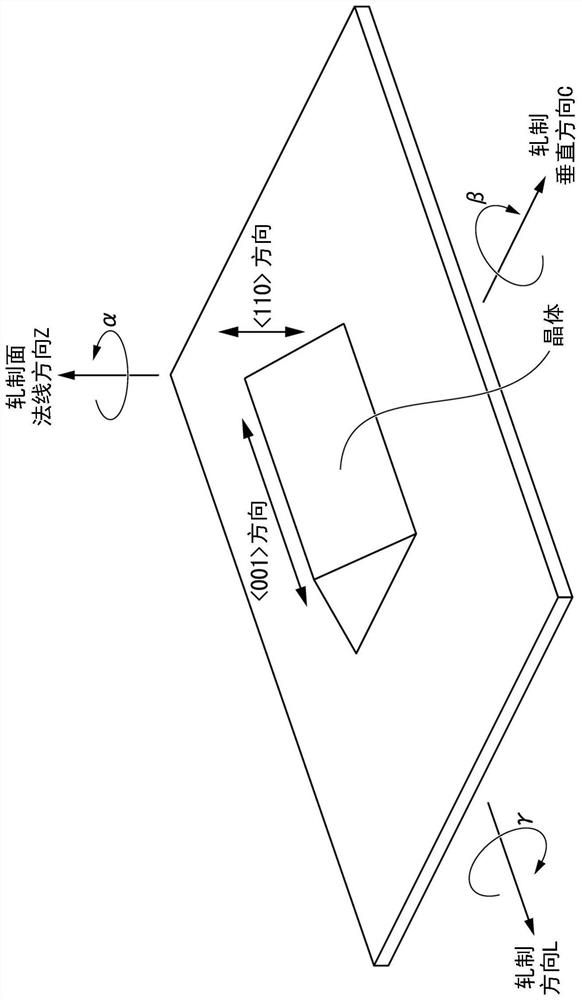

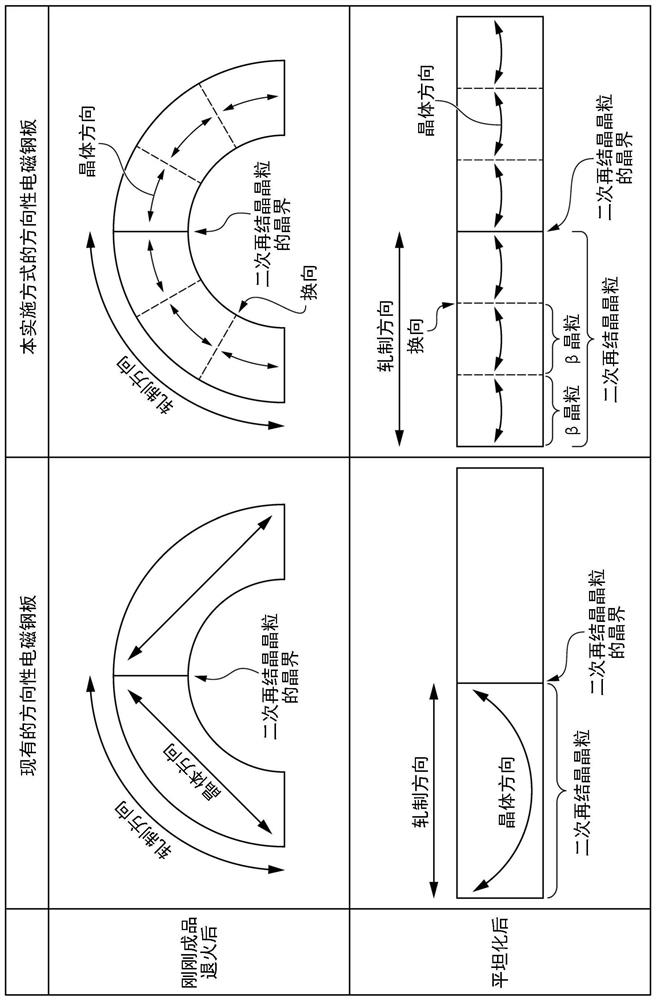

[0065] In the grain-oriented electrical steel sheet according to the first embodiment of the present invention, the secondary recrystallized grains are divided into a plurality of regions with slightly different off-angles β. That is, the grain-oriented electrical steel sheet of the present embodiment has not only grain boundaries with relatively large angle differences corresponding to the grain boundaries of the secondary recrystallized grains, but also local small grains that divide the secondary recrystallized grains. Angled grain boundaries.

[0066] Specifically, the grain-oriented electrical steel sheet of the present embodiment has the following chemical composition: containing in mass %: Si: 2.0 to 7.0%, Nb: 0 to 0.030%, V: 0 to 0.030%, Mo: 0 to 0.030 %, Ta: 0 to 0.030%, W: 0 to 0.030%, C: 0 to 0.0050%, Mn: 0 to 1.0%, S: 0 to 0.0150%, Se: 0 to 0.0150%, Al: 0 to 0.0650% , N: 0 to 0.0050%, Cu: 0 to 0.40%, Bi: 0 to 0.010%, B: 0 to 0.080%, P: 0 to 0.50%, Ti: 0 to 0.0150%...

no. 2 Embodiment approach

[0108] Next, the grain-oriented electrical steel sheet according to the second embodiment of the present invention will be described below. In addition, in each embodiment described below, the point which is different from the said 1st Embodiment is mainly demonstrated, and about other characteristics, it is the same as that of the said 1st Embodiment, and a repeated description is abbreviate|omitted.

[0109] In the grain-oriented electrical steel sheet according to the second embodiment of the present invention, the grain size of the β grains in the rolling direction is smaller than the grain size of the secondary recrystallized grains in the rolling direction. That is, the grain-oriented electrical steel sheet of the present embodiment has β grains and secondary recrystallized grains whose grain sizes in the rolling direction are controlled.

[0110] Specifically, in the grain-oriented electrical steel sheet of the present embodiment, the average grain size in the rolling d...

no. 3 Embodiment approach

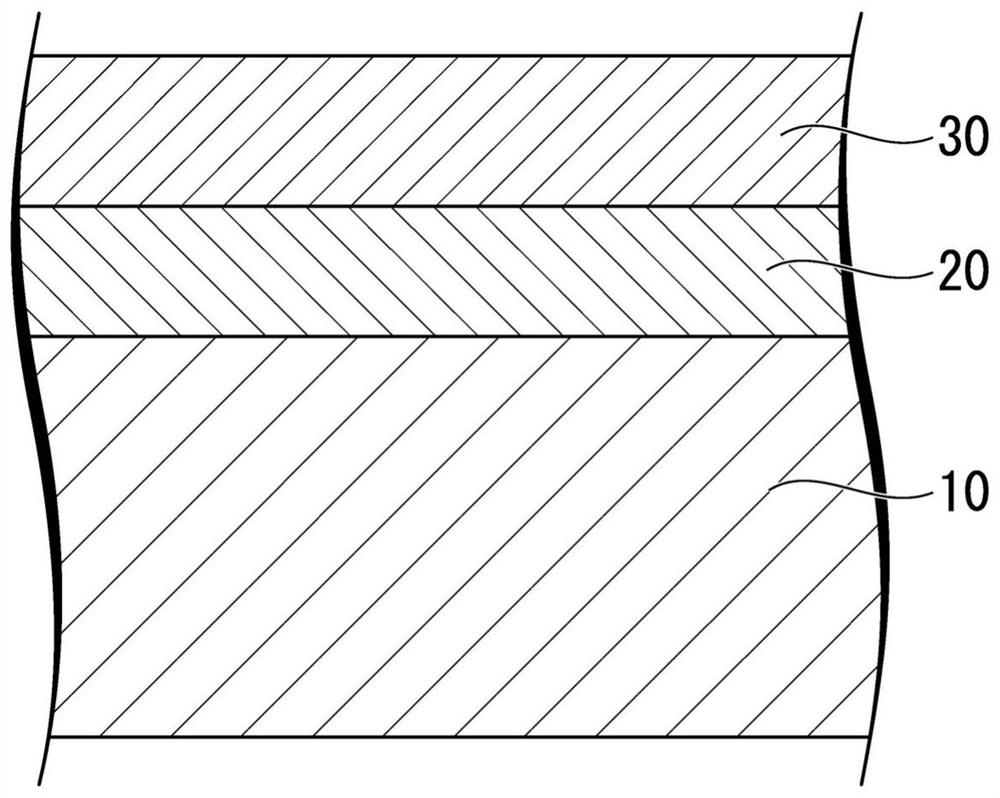

[0130] Next, the grain-oriented electrical steel sheet according to the third embodiment of the present invention will be described below. Hereinafter, the differences from the above-described embodiments will be mainly described, and overlapping descriptions will be omitted.

[0131] In the grain-oriented electrical steel sheet according to the third embodiment of the present invention, the grain size of the β crystal grains in the vertical direction of rolling is smaller than the grain size of the secondary recrystallized grains in the vertical direction of rolling. That is, the grain-oriented electrical steel sheet of the present embodiment has β grains and secondary recrystallized grains whose grain sizes in the vertical direction of rolling are controlled.

[0132] Specifically, in the grain-oriented electrical steel sheet of the present embodiment, the average grain size in the direction C perpendicular to the rolling obtained based on the boundary condition BA is define...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com