grain-oriented electrical steel sheet

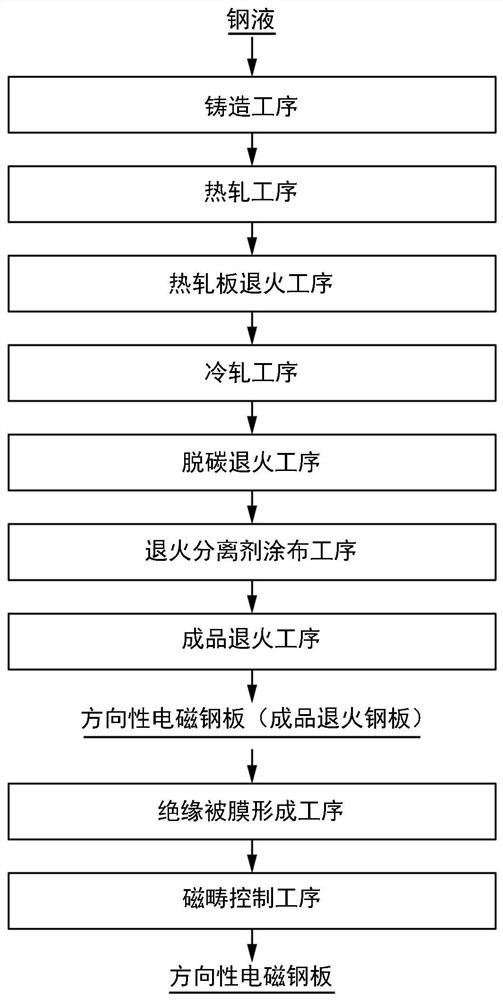

An electromagnetic steel plate and directional technology, applied in the direction of circuits, magnetic objects, magnetic materials, etc., can solve the problems of large crystal grains and hinder the improvement of magnetic flux density, and achieve the effect of improving magnetostriction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach

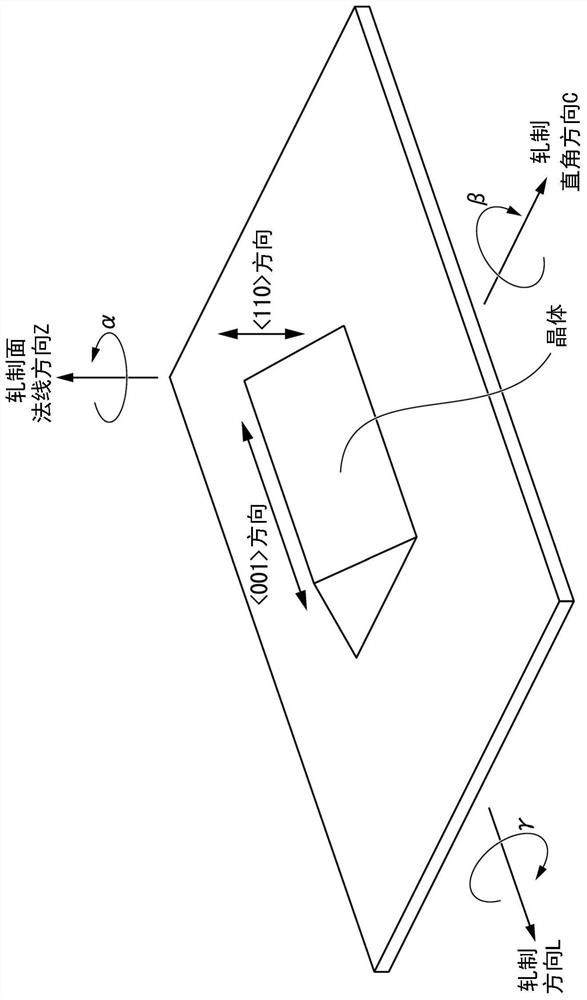

[0062] In the grain-oriented electrical steel sheet according to the first embodiment of the present invention, the secondary recrystallized grains are divided into a plurality of regions with slightly different off-angles γ. That is, the grain-oriented electrical steel sheet of the present embodiment has not only grain boundaries with relatively large angle differences corresponding to the grain boundaries of the secondary recrystallized grains, but also grains with small inclination angles locally dividing the secondary recrystallized grains. boundary.

[0063] Specifically, the grain-oriented electrical steel sheet of the present embodiment has the following chemical composition: Si: 2.0 to 7.0%, Nb: 0 to 0.030%, V: 0 to 0.030%, Mo: 0 to 0.030% in mass % , Ta: 0 to 0.030%, W: 0 to 0.030%, C: 0 to 0.0050%, Mn: 0 to 1.0%, S: 0 to 0.0150%, Se: 0 to 0.0150%, Al: 0 to 0.0650%, N: 0 to 0.0050%, Cu: 0 to 0.40%, Bi: 0 to 0.010%, B: 0 to 0.080%, P: 0 to 0.50%, Ti: 0 to 0.0150%, Sn:...

no. 2 Embodiment approach

[0105] Next, the grain-oriented electrical steel sheet according to the second embodiment of the present invention will be described below. In addition, in each embodiment described below, it demonstrates centering on the difference from the said 1st Embodiment, about other characteristics, it is set as the same thing as the said 1st Embodiment, and a repeated description is abbreviate|omitted.

[0106] In the grain-oriented electrical steel sheet according to the second embodiment of the present invention, the grain size of the γ grains in the rolling direction is smaller than the grain size of the secondary recrystallized grains in the rolling direction. That is, the grain-oriented electrical steel sheet of the present embodiment has γ grains and secondary recrystallized grains whose grain sizes are controlled with respect to the rolling direction.

[0107] Specifically, in the grain-oriented electrical steel sheet of the present embodiment, the average grain size in the rol...

no. 3 Embodiment approach

[0119] Next, the grain-oriented electrical steel sheet according to the third embodiment of the present invention will be described below. Hereinafter, the differences from the above-described embodiments will be mainly described, and overlapping descriptions will be omitted.

[0120] In the grain-oriented electrical steel sheet according to the third embodiment of the present invention, the grain size of the γ crystal grains in the direction perpendicular to the rolling direction is smaller than the grain size of the secondary recrystallized grains in the direction perpendicular to the rolling direction. That is, the grain-oriented electrical steel sheet of the present embodiment has γ grains and secondary recrystallized grains whose grain sizes are controlled in the direction perpendicular to the rolling direction.

[0121] Specifically, in the grain-oriented electrical steel sheet of the present embodiment, the average grain size in the direction C at right angles to the ro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com