Grain oriented electrical steel flat products with insulating coating

A technology of grain orientation and insulating coating, applied in the coating process of metal materials, layered products, magnetic properties of inorganic materials, etc., to achieve the effect of excellent density and low porosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0096]A series of aqueous compositions for insulating coatings according to the invention were prepared according to the components given in Table 1 below. A set of control solutions is also included in this series of compositions for comparative purposes, and this protocol does not form part of the present invention. If not otherwise stated, all percentages are given in % by weight, and for rows 1-21 of Table 1, the % by weight values are based on the total weight of the slurry composition.

Embodiment 2

[0098] The key physicochemical properties of the composition prepared in Example 1 were evaluated. In particular, its sedimentation behaviour, viscosity and gelation rate were studied. The results are summarized in Table 2 below.

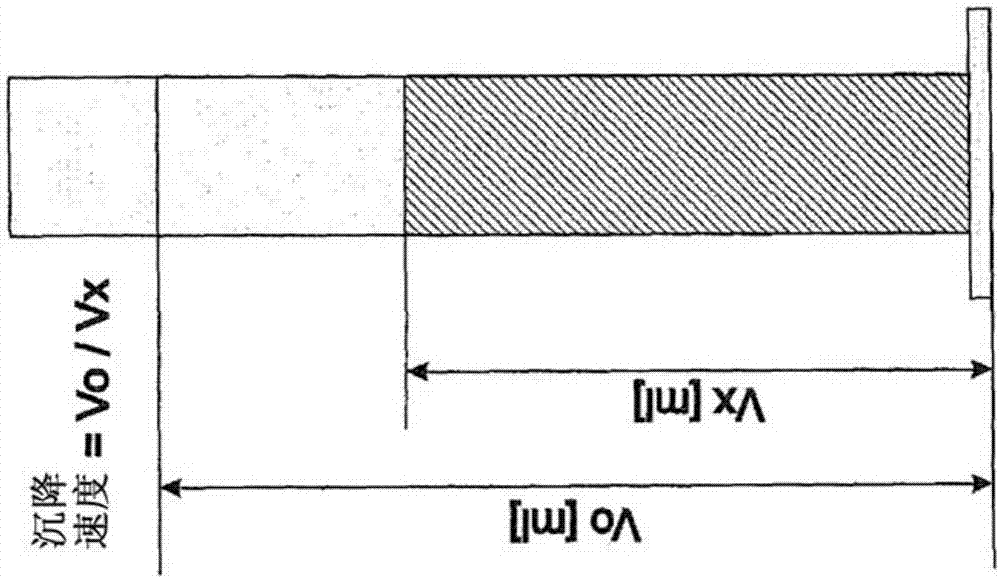

[0099] according to figure 2 The method shown determines the sedimentation behavior as a function of time. For this, the composition was incubated for 6 hours at room temperature. Where phase separation was observed, the volumes of the two phases were determined. The sedimentation after 6 hours is given as the volume of the deposited phase as a percentage of the total volume (see figure 2 , 100*V 0 / V x ).

[0100] The viscosity of each solution was measured immediately after its preparation. Viscosity measurements were performed using a Brookfield DV-II+ viscometer (spindle: LV1, drive: 50 rpm, T=50°C).

[0101] The parameter "time for gelation" in Table 2 refers to the time required until the solution is gelled. The time point of gelat...

Embodiment 3

[0105] A 0.30 mm thick grain oriented electrical steel sample (ie, with a forsterite coating according to the prior art) was coated with the treatment solutions 1-21 listed in Table 1 in the box-annealed state. The coating is performed using a roll of a coater. The thickness of the coating after baking was measured and determined to be 2.25 μm by SEM FEG microscope or magnetic induction device (eg Fischer Permascope). The baking temperature varies from 800°C to 950°C.

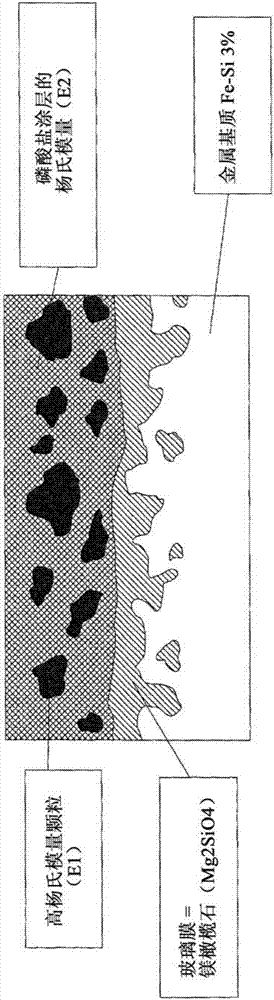

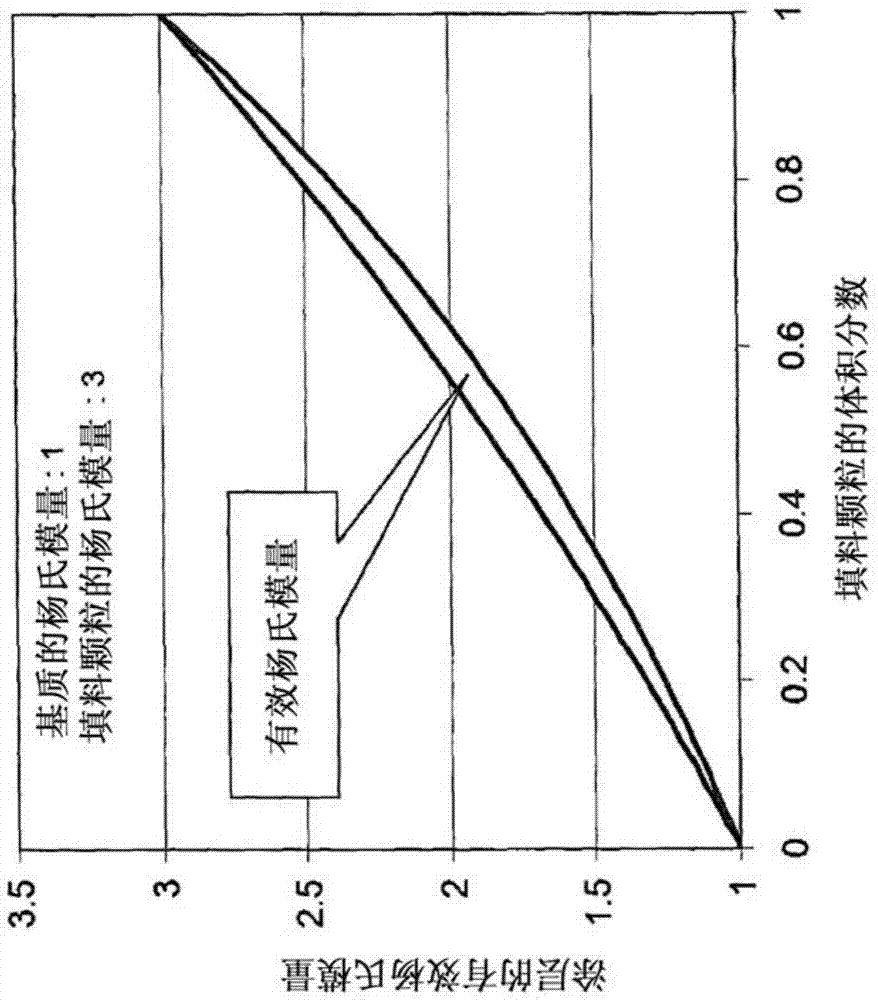

[0106] It was found that the addition of core-shell filler particles to the composition according to the invention is accompanied by an enhanced Young's modulus, the so-called effective Young's modulus, measured by the Oberst beam method, of the resulting coating.

[0107] This effect can be explained by the Hashin-Shtrikman model according to:

[0108]

[0109] C1 volume fraction of filled particles

[0110] C2 volume fraction of finished coating matrix: C2=1-C1

[0111] image 3 A data graph showing t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com