Double-layer water bath type high-temperature and high-pressure conditioning sterilization pot

A high temperature and high pressure, conditioning and sterilization technology, applied in water supply equipment, food science, food preservation and other directions, can solve the problems of poor sterilization effect and low heating temperature, and achieve the effect of improving sterilization effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

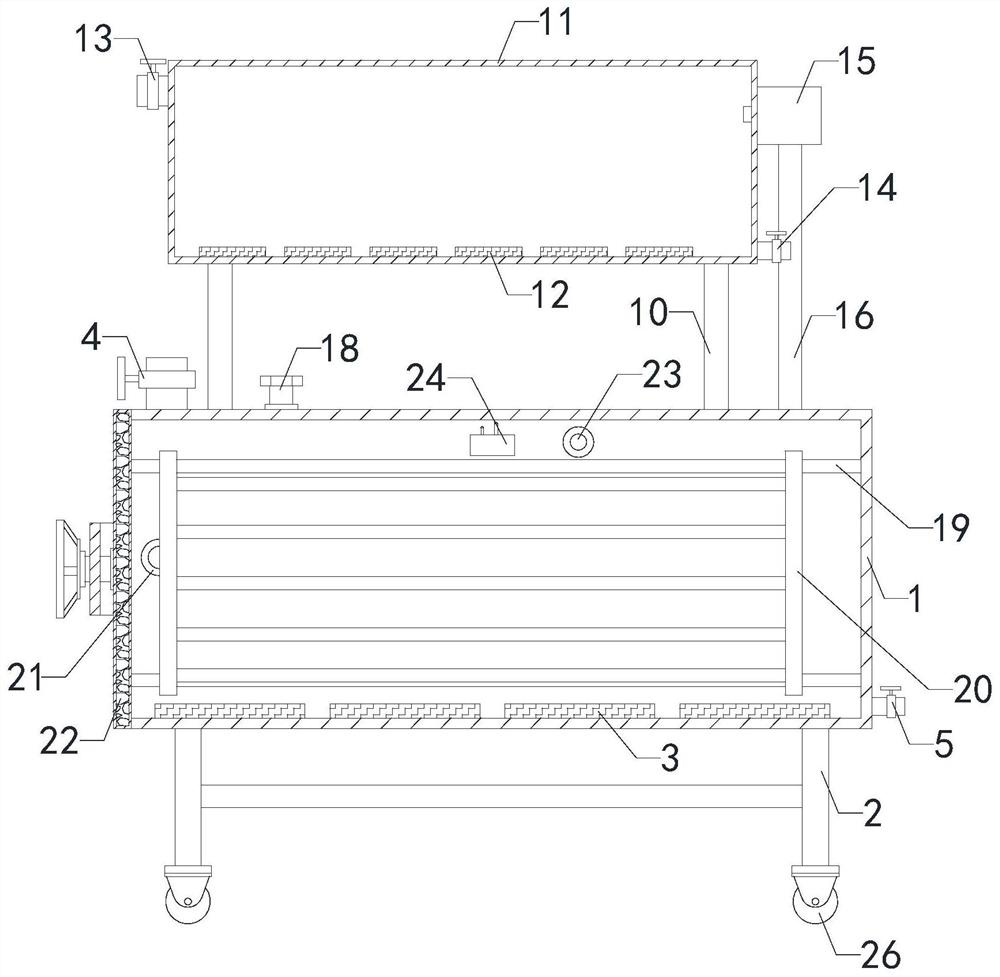

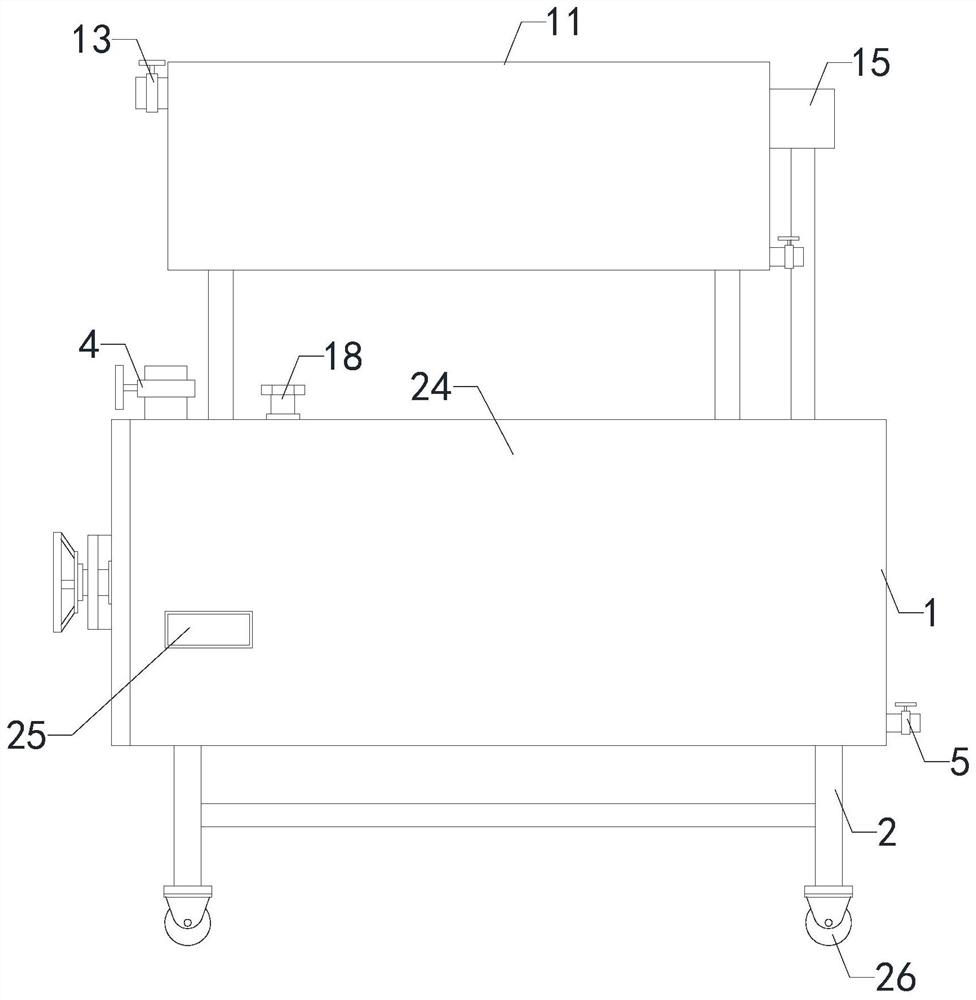

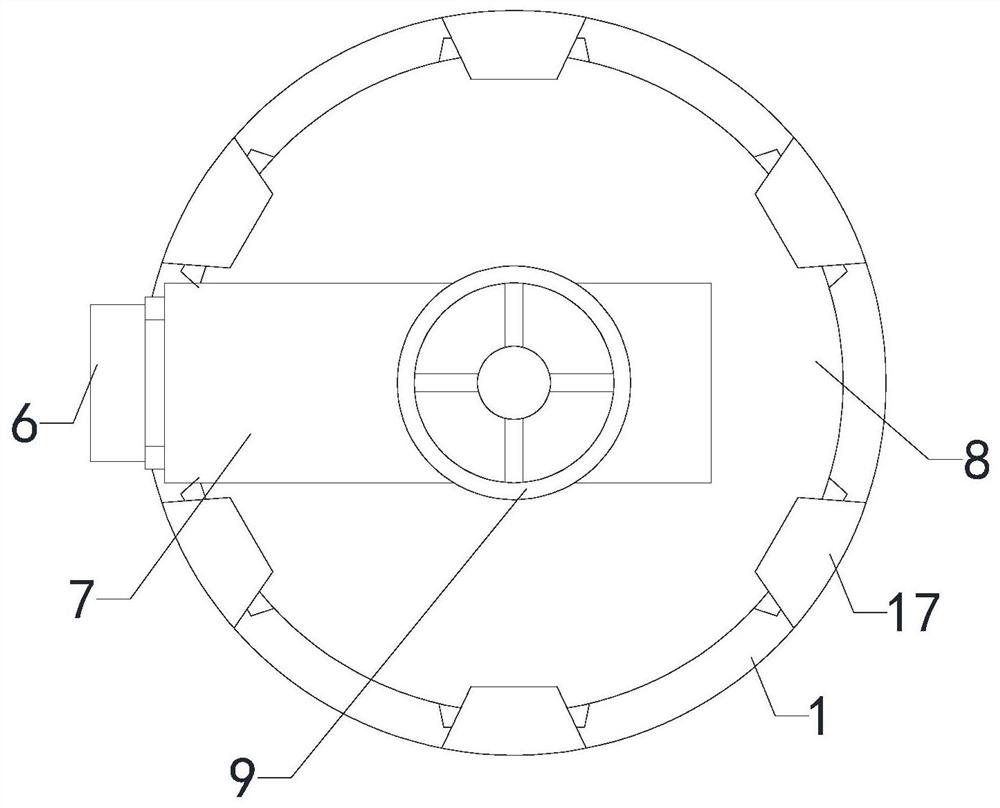

[0016] Such as Figure 1 to Figure 3 As shown, the double-layer water bath type high temperature and high pressure conditioning sterilizer of the present invention includes a sterilizer 1, a support frame 2, multiple sets of first heating plates 3, a first water inlet valve 4, a first drain valve 5, and a first fixing plate 6. Second fixed plate 7, safety door 8, rotary handle 9, multiple sets of brackets 10, steam generating chamber 11, multiple sets of second heating plates 12, second water inlet valve 13, second drain valve 14, exhaust pump 15 and Exhaust pipe 16, the top of support frame 2 is connected with the bottom end of sterilizing pot 1, and the left end of ster...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap