Cooking equipment control method, cooking equipment and readable storage medium

A technology of cooking equipment and a control method, which is applied in the field of cooking equipment, readable storage media, and cooking equipment control, can solve problems such as the inability to cook rice noodles, achieve simplified operation, improve utilization rate, and reduce kitchen space occupancy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

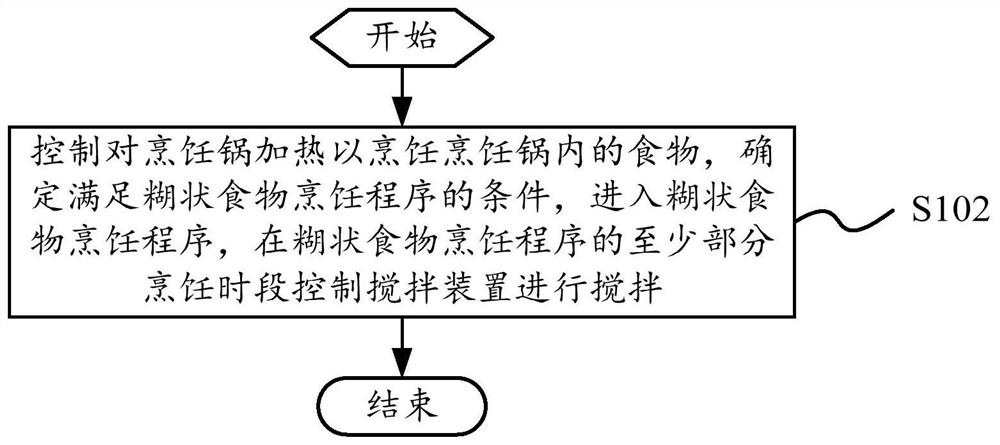

Method used

Image

Examples

specific Embodiment 1

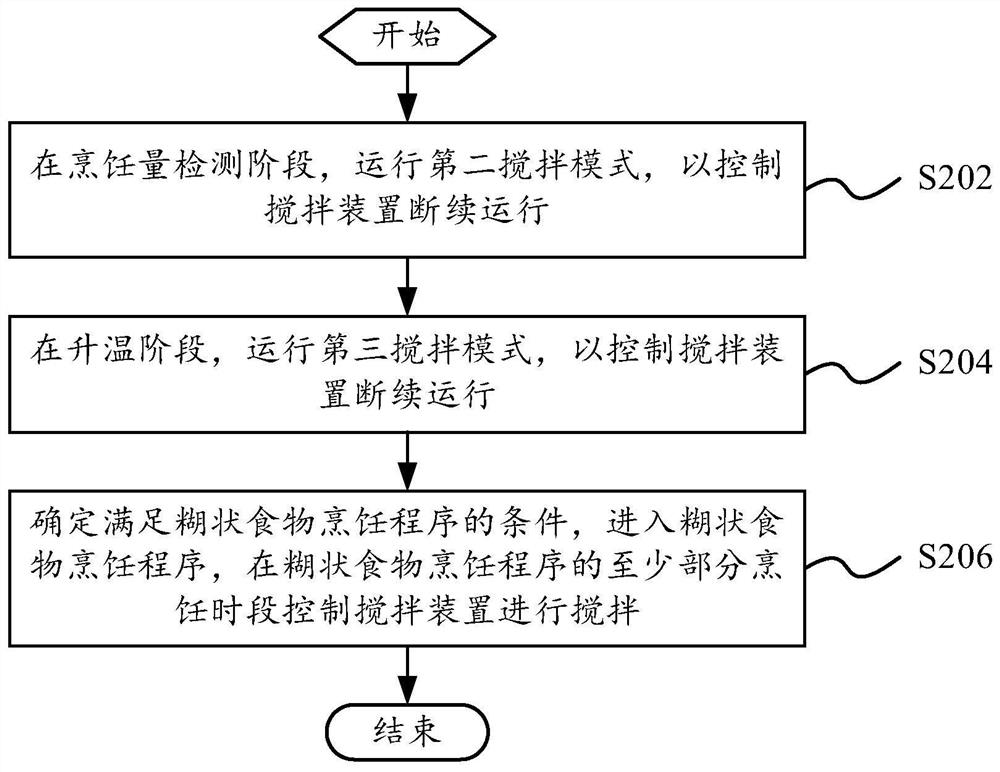

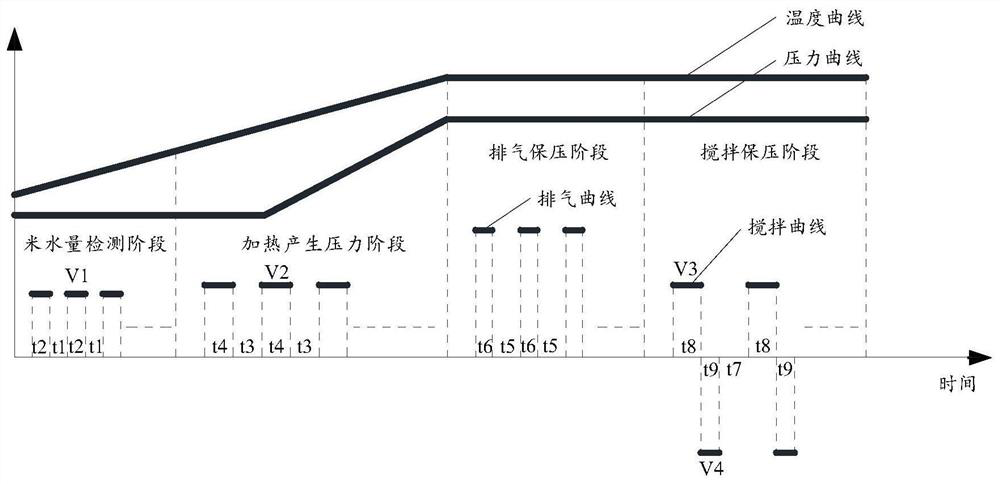

[0120] Such as image 3 As shown, the user selects the rice noodle function file, the cooking starts, and the program enters the heating stage. The temperature sensor detects the temperature T at the bottom of the cooking pot, and the amount of rice water in the pot is judged by calculating the amount of temperature increase per unit time or the time required for the temperature to increase by a specific value. During the process of judging the amount of rice water, the stirring device stirs every time t1, and the stirring time is t2. Speed V1 improves the uniformity of temperature distribution of rice water in the pot, ensures that the temperature of rice water in the pot is consistent in the vertical direction, makes temperature measurement accurate, and ensures accurate judgment of rice water volume. After judging the amount of rice water, the heating device continues to work to heat the cooking pot and food. In this stage, the stirring device is used every time t3, the ...

specific Embodiment 2

[0123] The difference between the second embodiment and the first embodiment is that no stirring is carried out during the pressure holding stage, and the stirring is carried out after the pressure is lowered to normal pressure, or the heating and stirring is carried out after adding auxiliary materials after normal pressure.

[0124] Specifically, as Figure 4 As shown, the user selects the rice noodle function file, the cooking starts, and the program enters the heating stage. The temperature sensor detects the temperature T at the bottom of the cooking pot, and the amount of rice water in the pot is judged by calculating the amount of temperature increase per unit time or the time required for the temperature to increase by a specific value. During the process of judging the amount of rice water, the stirring device stirs every time t1, and the stirring time is t2. Speed V1 improves the uniformity of temperature distribution of rice water in the pot, ensures that the temp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com