Honing head capable of achieving single-double feeding and hole diameter adjusting for cylinder body and cylinder sleeve

A honing head and cylinder block technology, applied in the field of cylinder block honing, can solve problems such as unfavorable economic benefits, affecting processing efficiency, and large workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

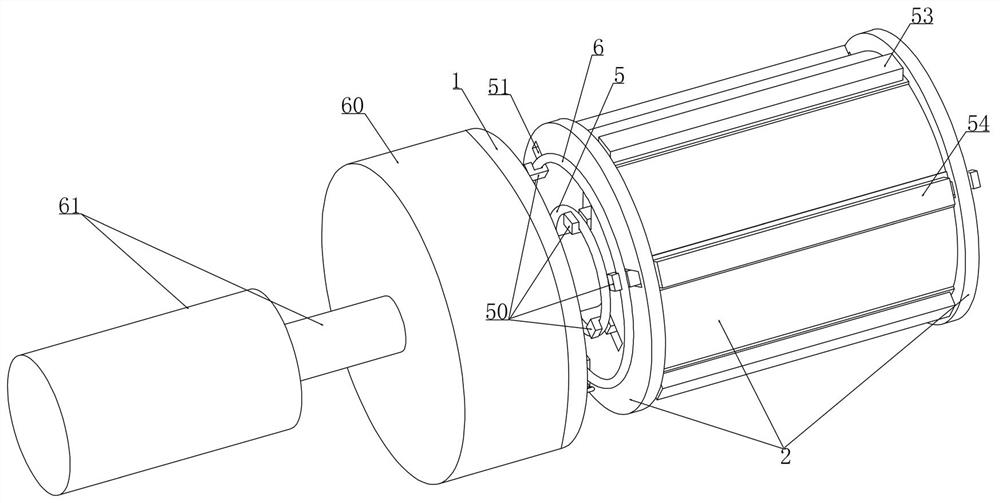

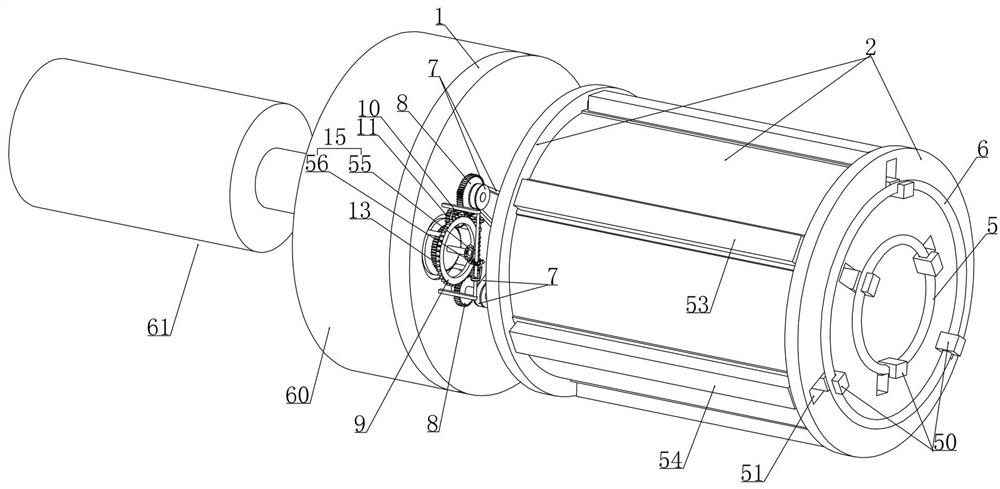

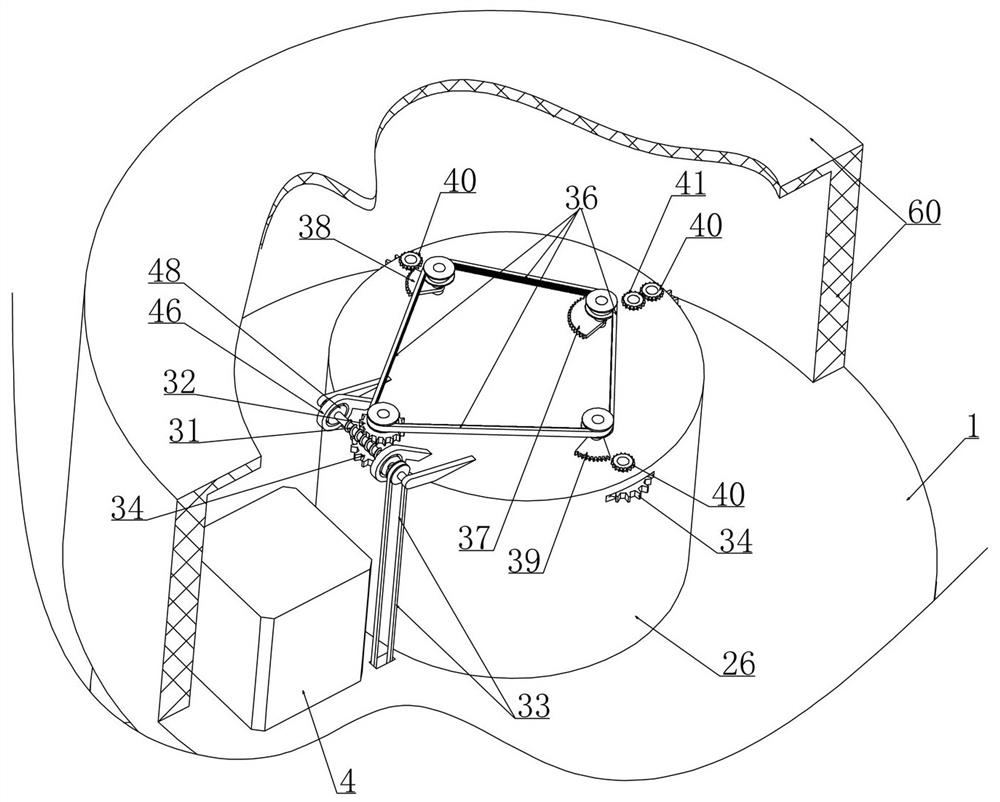

[0042] Embodiment 1, this embodiment provides a honing head with single and double feed for cylinder block and cylinder liner and adjustable hole diameter, refer to the attached figure 1 As shown, including the bearing plate 1, we rotate the bearing cylinder 2 on the bearing plate 1 and we are integrally provided with a sealing cylinder 60 on the bearing plate 1, and the sealing cylinder 60 is driven by a reciprocating push rod 61 (the reciprocating push The rod 61 can be an electric push rod 43), that is, the carrying cylinder 2 moves linearly and reciprocatingly under the action of the reciprocating push rod 61. The fine grinding base 3 and coarse grinding base 4 refer to the attached figure 1 As shown, several fine grinding bases 3 and coarse grinding bases 4 extend along the length direction of the bearing cylinder 2, and we make several fine grinding bases 3 and coarse grinding bases 4 alternately set up when setting (that is, make the fine grinding bases 3 and coarse gr...

Embodiment 2

[0048] Embodiment 2, on the basis of embodiment 1, with reference to appended Figure 9 As shown, the drive switching device includes a worm gear ring 9 rotatably mounted on the lower end surface of the bearing plate 1, referring to the attached Figure 11 As shown, we rotate and install a rotating shaft 12 on the upper end of the worm wheel ring 9, and the first gear 10 that is inherently matched with the two transmission gears 8 is placed on the rotating shaft 12. One-way gear 11, the one-way gear 11 meshes with the driving gear 13 that is rotatably mounted on the bearing plate 1. When we set it up, the centers of the two transmission gears 8 are distributed on a circle with the center of the driving gear 13 as the center and different diameters. (the distance between the center of circle of the larger transmission gear 8 of diameter and the center of circle of driving gear 13 is greater than the distance between the circle of the smaller transmission gear 8 of diameter and ...

Embodiment 3

[0054] Embodiment 3, on the basis of embodiment 1, with reference to appended Figure 13 As shown, we set a cylinder 18 coaxially in the bearing cylinder 2 and the bearing cylinder 2 is installed on the bearing plate 1 through the rotation of the cylinder 18, and the first belt drive 7 and the cylinder 18 pass through one end of the bearing cylinder 2 upwards. Connected, the radial push device includes a first push rod 19 coaxially arranged in the bearing cylinder 2 and axially slidingly fitted with the cylinder 18, refer to the attached Figure 14 As shown, the first push rod 19 passes through the bearing cylinder 2 at intervals upward (the first push rod 19 does not contact the bearing cylinder 2) and one end of the penetration is connected with the lifting mechanism. Refer to the attached Figure 15 As shown, we installed a second push cylinder 20 axially sliding on the outer wall of the cylinder 18, and we installed a number of precision grinding extrusion devices on the o...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap